Vibration monitoring provides real-time data on the mechanical integrity of marine engines by detecting imbalances and misalignments through frequency analysis. Acoustic emission testing captures high-frequency stress waves generated by crack formation or material degradation, offering early detection of structural faults. Combining these techniques enhances predictive maintenance, reducing downtime and improving vessel safety.

Table of Comparison

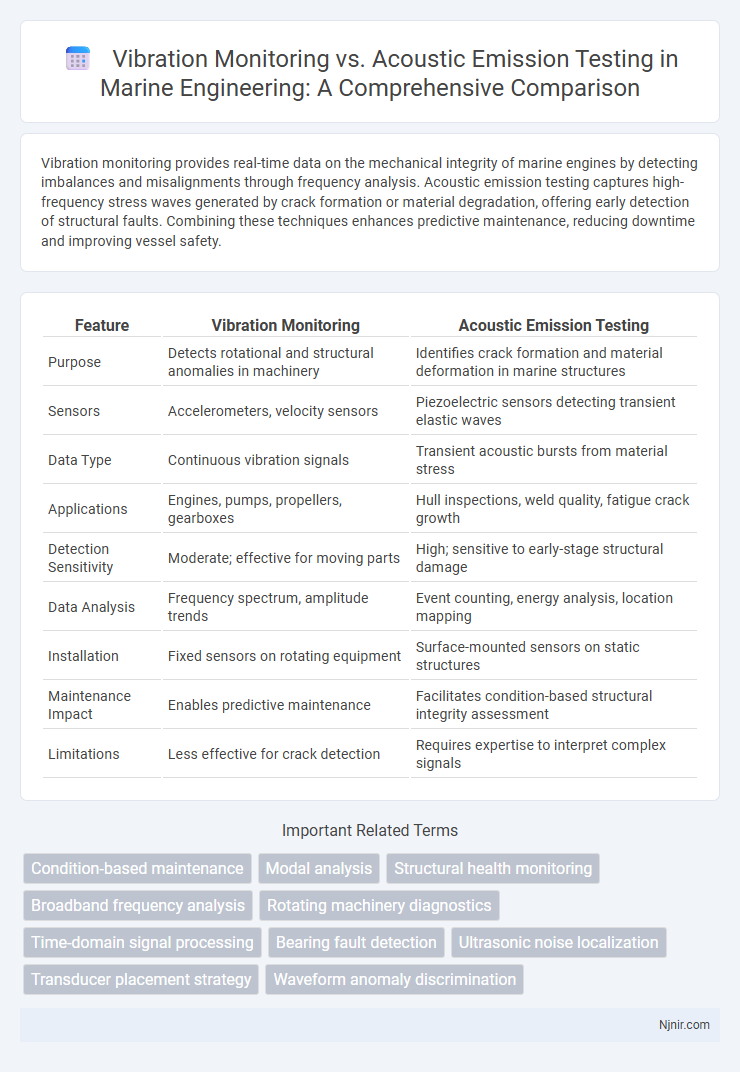

| Feature | Vibration Monitoring | Acoustic Emission Testing |

|---|---|---|

| Purpose | Detects rotational and structural anomalies in machinery | Identifies crack formation and material deformation in marine structures |

| Sensors | Accelerometers, velocity sensors | Piezoelectric sensors detecting transient elastic waves |

| Data Type | Continuous vibration signals | Transient acoustic bursts from material stress |

| Applications | Engines, pumps, propellers, gearboxes | Hull inspections, weld quality, fatigue crack growth |

| Detection Sensitivity | Moderate; effective for moving parts | High; sensitive to early-stage structural damage |

| Data Analysis | Frequency spectrum, amplitude trends | Event counting, energy analysis, location mapping |

| Installation | Fixed sensors on rotating equipment | Surface-mounted sensors on static structures |

| Maintenance Impact | Enables predictive maintenance | Facilitates condition-based structural integrity assessment |

| Limitations | Less effective for crack detection | Requires expertise to interpret complex signals |

Introduction to Condition Monitoring in Marine Engineering

Vibration monitoring detects mechanical faults by analyzing equipment oscillations, providing early warning of imbalance, misalignment, and bearing failures in marine engines and machinery. Acoustic emission testing captures high-frequency sound waves generated by structural defects or crack propagation within ship components, enabling real-time condition assessment without disassembly. Both techniques enhance predictive maintenance in marine engineering, improving vessel reliability and reducing downtime through continuous condition monitoring.

Fundamentals of Vibration Monitoring

Vibration monitoring detects mechanical issues by measuring oscillations and frequency changes in rotating equipment, providing critical data on imbalance, misalignment, and bearing faults. Sensors such as accelerometers capture vibration signals that are analyzed using Fast Fourier Transform (FFT) to identify specific fault frequencies. This fundamental approach enables early detection and predictive maintenance, reducing downtime and equipment failure.

Principles of Acoustic Emission Testing

Acoustic Emission Testing (AET) detects transient elastic waves generated by the rapid release of energy from localized sources within a material, such as crack formation or plastic deformation. Unlike vibration monitoring, which measures overall dynamic response and machine movement, AET focuses on high-frequency stress waves to identify and locate active defects in real time. This principle allows for early fault detection by capturing internal damage mechanisms before they manifest as increased vibration levels.

Key Differences between Vibration Monitoring and Acoustic Emission

Vibration monitoring measures mechanical oscillations and motion patterns in equipment to detect imbalance, misalignment, or bearing defects, primarily focusing on low-frequency signals. Acoustic emission testing detects transient elastic waves generated by rapid internal material changes such as crack growth or leaks, emphasizing high-frequency stress waves for early fault detection. Vibration monitoring excels in identifying overall machine condition, while acoustic emission provides precise insights into active defect generation and material integrity.

Applications of Vibration Monitoring in Marine Systems

Vibration monitoring in marine systems is essential for detecting early signs of bearing failure, misalignment, and imbalance in ship engines, propellers, and pumps, enhancing operational reliability and safety. It provides continuous condition assessment of rotating machinery, enabling predictive maintenance that reduces downtime and prevents catastrophic failures. By analyzing vibration patterns, marine engineers can optimize equipment performance and extend the lifespan of critical components under harsh marine environmental conditions.

Marine Applications of Acoustic Emission Testing

Acoustic Emission Testing (AET) in marine applications enables real-time detection of structural faults, corrosion, and fatigue cracks in ship hulls and offshore platforms, offering higher sensitivity to micro-level defects compared to vibration monitoring. Unlike vibration monitoring, which primarily tracks mechanical imbalances and bearing wear through oscillation patterns, AET detects high-frequency transient elastic waves produced by active crack growth or material deformation, providing early warning for critical failures. The deployment of AET in marine environments enhances safety and maintenance efficiency by facilitating continuous monitoring underwater and in hard-to-access areas where vibration sensors may be less effective.

Sensitivity and Accuracy: Vibration vs Acoustic Emission

Vibration monitoring detects overall machine motion patterns, offering moderate sensitivity to early-stage faults but limited accuracy in pinpointing defect locations. Acoustic emission testing captures high-frequency stress waves from active defects, providing higher sensitivity and precise accuracy in identifying and locating damage initiation. Combining both methods enhances reliability by leveraging vibration's broad diagnostic scope with acoustic emission's detailed defect characterization.

Installation and Maintenance Considerations

Vibration monitoring requires careful sensor placement on rotating machinery, ensuring secure mounting to avoid signal distortion and regular calibration for accurate data collection. Acoustic emission testing demands strategic positioning of sensitive transducers on areas prone to stress or cracking, with meticulous surface preparation to enhance signal transmission and frequent coupling maintenance to sustain detection sensitivity. Both techniques involve periodic system checks and data validation, but acoustic emission testing often entails more complex setup due to environmental noise interference and equipment sensitivity.

Cost-Effectiveness in Marine Vessel Diagnostics

Vibration monitoring offers a cost-effective solution for routine marine vessel diagnostics by detecting imbalances and mechanical faults early, reducing downtime and maintenance expenses. Acoustic emission testing, while more sensitive for detecting crack propagation and structural failures, generally involves higher initial investment and specialized equipment, making it more suitable for targeted inspections. Combining both methods can optimize diagnostic accuracy and cost-efficiency by leveraging vibration monitoring's continuous tracking with acoustic emission's precise fault detection.

Future Trends in Marine Condition Monitoring Technologies

Future trends in marine condition monitoring technologies emphasize the integration of vibration monitoring and acoustic emission testing with advanced AI-driven analytics for predictive maintenance and real-time fault detection. Enhanced sensor miniaturization and wireless communication facilitate continuous data acquisition from critical marine equipment such as engines, propellers, and hull structures. The convergence of these technologies supports improved asset reliability, reduced downtime, and optimized operational efficiency in modern maritime operations.

Condition-based maintenance

Condition-based maintenance leverages vibration monitoring for early fault detection in rotating machinery while acoustic emission testing excels in identifying material cracks and structural changes, providing complementary insights for comprehensive equipment health assessment.

Modal analysis

Modal analysis enhances vibration monitoring by precisely identifying structural modes, while acoustic emission testing detects real-time crack initiation and growth for comprehensive fault diagnosis.

Structural health monitoring

Vibration monitoring detects structural defects by analyzing frequency changes, while acoustic emission testing identifies crack propagation through transient elastic waves, both enhancing structural health monitoring accuracy.

Broadband frequency analysis

Broadband frequency analysis in vibration monitoring captures a wide range of machine vibrations for fault diagnosis, while acoustic emission testing detects transient high-frequency waves generated by material stress or crack propagation for early fault detection.

Rotating machinery diagnostics

Vibration monitoring detects imbalance, misalignment, and bearing defects in rotating machinery by analyzing vibration signals, while acoustic emission testing identifies early-stage faults such as crack growth and material deformation through high-frequency stress wave detection.

Time-domain signal processing

Time-domain signal processing in vibration monitoring captures displacement, velocity, and acceleration data to detect machine faults, while acoustic emission testing analyzes high-frequency transient waveforms to identify crack initiation and material degradation early.

Bearing fault detection

Vibration monitoring detects bearing faults by analyzing mechanical oscillations, while acoustic emission testing identifies early-stage cracks through high-frequency stress wave detection.

Ultrasonic noise localization

Ultrasonic noise localization in acoustic emission testing provides more precise detection of high-frequency signals for early fault identification compared to conventional vibration monitoring, enhancing structural health assessment accuracy.

Transducer placement strategy

Effective transducer placement in vibration monitoring targets bearings and shafts for early fault detection, while acoustic emission testing strategically positions sensors near stress concentration zones to capture high-frequency wave emissions from crack initiation and growth.

Waveform anomaly discrimination

Waveform anomaly discrimination in vibration monitoring provides precise detection of mechanical faults by analyzing vibration signals, whereas acoustic emission testing excels in identifying energy releases from crack initiation through high-frequency waveforms.

vibration monitoring vs acoustic emission testing Infographic

njnir.com

njnir.com