Reverse osmosis uses semi-permeable membranes to filter seawater, efficiently removing salts and impurities through high-pressure systems, making it energy-efficient and compact for marine applications. Evaporator desalination relies on heat to evaporate seawater, condensing pure water afterward, which consumes more energy but tolerates higher salinity and fouling levels. Both methods are crucial onboard vessels, with reverse osmosis preferred for fuel economy and evaporators favored for robustness in challenging water conditions.

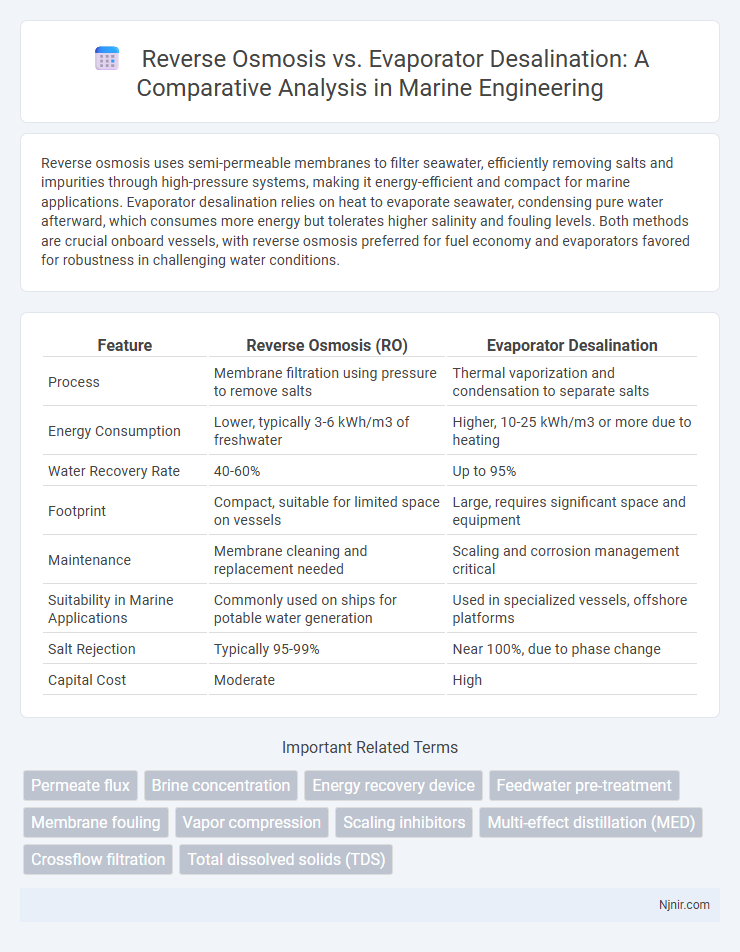

Table of Comparison

| Feature | Reverse Osmosis (RO) | Evaporator Desalination |

|---|---|---|

| Process | Membrane filtration using pressure to remove salts | Thermal vaporization and condensation to separate salts |

| Energy Consumption | Lower, typically 3-6 kWh/m3 of freshwater | Higher, 10-25 kWh/m3 or more due to heating |

| Water Recovery Rate | 40-60% | Up to 95% |

| Footprint | Compact, suitable for limited space on vessels | Large, requires significant space and equipment |

| Maintenance | Membrane cleaning and replacement needed | Scaling and corrosion management critical |

| Suitability in Marine Applications | Commonly used on ships for potable water generation | Used in specialized vessels, offshore platforms |

| Salt Rejection | Typically 95-99% | Near 100%, due to phase change |

| Capital Cost | Moderate | High |

Introduction to Desalination in Marine Engineering

Reverse osmosis and evaporator desalination are two primary methods for removing salt from seawater in marine engineering. Reverse osmosis uses semi-permeable membranes to filter out salt ions, offering energy efficiency and compact design suitable for ship applications. Evaporator desalination relies on thermal processes to vaporize and condense freshwater, providing robustness in handling variable water quality and higher salt concentrations.

Principles of Reverse Osmosis Technology

Reverse osmosis technology relies on a semipermeable membrane to separate dissolved salts and impurities from water by applying pressure greater than the osmotic pressure, forcing freshwater through the membrane while retaining contaminants. This process efficiently removes up to 99% of dissolved solids, organic compounds, bacteria, and pyrogens, making it highly effective for desalination. Compared to evaporator desalination, which uses heat to vaporize water, reverse osmosis consumes significantly less energy and operates at lower temperatures, preserving water quality and reducing operational costs.

Fundamentals of Evaporator Desalination Systems

Evaporator desalination systems operate on the principle of phase change, where seawater is heated to produce vapor, leaving salts and impurities behind, and the vapor is then condensed into freshwater. These systems rely on thermal energy and utilize components such as evaporators, condensers, and heat exchangers to facilitate the separation of salt from water. Unlike reverse osmosis, which uses high-pressure membranes to filter water, evaporator desalination is less sensitive to water salinity and can handle higher concentrations of dissolved solids.

Energy Consumption: Reverse Osmosis vs Evaporators

Reverse osmosis (RO) desalination typically consumes between 3 to 6 kWh per cubic meter of freshwater produced, making it significantly more energy-efficient compared to evaporator-based methods, which can require 10 to 25 kWh per cubic meter due to the heat-intensive vaporization process. RO leverages high-pressure pumps to force water through semi-permeable membranes, reducing energy consumption by avoiding phase change, whereas evaporators rely on thermal energy to vaporize and condense water, often necessitating costly fuel or electricity inputs. Energy consumption differences directly impact operational costs and carbon footprints, positioning RO as the preferred technology for large-scale, energy-conscious desalination projects.

Water Quality and Purity Comparison

Reverse osmosis (RO) desalination produces water with consistently high purity, effectively removing up to 99% of dissolved salts, organic compounds, and microorganisms through semipermeable membranes. Evaporator desalination relies on phase change, producing near-distilled water that is extremely pure but can contain trace volatile compounds and requires complex control to prevent scaling and corrosion. RO water quality excels in removing a broad spectrum of contaminants rapidly and with lower energy use, whereas evaporator systems achieve ultra-pure output at higher operational costs and maintenance demands.

Space and Weight Considerations Onboard Ships

Reverse osmosis desalination systems offer significant advantages in space and weight efficiency onboard ships, utilizing compact membrane modules that reduce overall footprint compared to traditional evaporators. Evaporator desalination units require larger, heavier components due to their reliance on thermal processes and extensive heat exchangers, increasing ship weight and limiting available cargo space. Optimizing reverse osmosis systems enhances capacity while minimizing energy consumption and structural impact, making them more suitable for modern maritime applications demanding space and weight economy.

Maintenance and Operational Complexity

Reverse osmosis systems require regular membrane cleaning and replacement due to fouling, demanding skilled operation and consistent monitoring to maintain efficiency. Evaporator desalination involves complex thermal processes, requiring routine inspection of heat exchangers and scaling control, leading to higher energy consumption and maintenance complexity. Both methods necessitate trained personnel, but evaporators typically have more intensive operational oversight and repair costs compared to reverse osmosis units.

Environmental Impact and Brine Disposal

Reverse osmosis desalination generates highly concentrated brine with dissolved chemicals and requires energy-intensive membrane filtration, leading to significant energy consumption and potential marine toxicity if brine is discharged improperly. Evaporator desalination produces brine with reduced chemical additives and lower chemical pollutants but demands substantial thermal energy, often sourced from fossil fuels, contributing to greenhouse gas emissions. Effective brine disposal methods such as deep-well injection or zero liquid discharge minimize environmental harm in both processes but involve complex management and higher operational costs.

Cost Analysis: Installation and Lifecycle

Reverse osmosis desalination generally involves higher upfront installation costs due to advanced membrane technology and energy requirements, but benefits from lower operational expenses over its lifecycle due to energy-efficient pumps and modular scalability. Evaporator desalination systems typically incur substantial capital expenditure because of complex thermal components and boilers, with ongoing costs heavily influenced by fuel or energy consumption and frequent maintenance needs. When analyzing total lifecycle costs, reverse osmosis often proves more cost-effective for medium to large-scale plants, while evaporators may be viable for niche applications with access to low-cost thermal energy sources.

Application Suitability and Selection Criteria

Reverse osmosis (RO) excels in treating brackish water and seawater with moderate salinity, offering energy-efficient operation for municipal and industrial applications, while evaporators are preferred for high-salinity brines and zero liquid discharge requirements due to their ability to handle concentrated feedwaters. Selection criteria hinge on factors like feedwater quality, energy availability, operational costs, and desired water recovery rates, with RO favored for large-scale potable water production and evaporators suited for industrial waste minimization and resource recovery. Evaluating site-specific parameters and environmental impact further guides the optimal desalination technology choice.

Permeate flux

Reverse osmosis achieves higher permeate flux rates of 20-40 L/m2*hr compared to evaporators, which typically have lower flux rates around 5-15 L/m2*hr due to thermal and mass transfer limitations.

Brine concentration

Reverse osmosis achieves higher brine concentration limits around 70,000 ppm total dissolved solids compared to evaporator desalination, which can concentrate brine beyond saturation but involves higher energy consumption and risk of scaling.

Energy recovery device

Reverse osmosis desalination utilizes energy recovery devices that significantly reduce energy consumption by capturing and reusing high-pressure brine energy, whereas evaporator desalination relies on thermal energy with limited energy recovery options, resulting in higher overall energy use.

Feedwater pre-treatment

Reverse osmosis requires extensive feedwater pre-treatment including filtration and chemical dosing to prevent membrane fouling, whereas evaporator desalination demands less rigorous pre-treatment but higher energy input to handle feedwater impurities.

Membrane fouling

Reverse osmosis experiences greater membrane fouling due to particulate and biofilm accumulation, whereas evaporators face less fouling but higher energy consumption and scaling issues.

Vapor compression

Vapor compression desalination uses mechanical vapor recompression to enhance energy efficiency compared to traditional evaporators, offering a more cost-effective and sustainable alternative to reverse osmosis for high-salinity water treatment.

Scaling inhibitors

Scaling inhibitors in reverse osmosis desalination prevent mineral deposits on membranes, enhancing system efficiency, while evaporator desalination relies less on chemical inhibitors due to thermal processes but may still require anti-scaling agents to maintain heat transfer surfaces.

Multi-effect distillation (MED)

Multi-effect distillation (MED) desalination uses multiple evaporator stages to efficiently produce fresh water by sequentially condensing steam under reduced pressure, offering lower energy consumption compared to traditional evaporators and often complementing reverse osmosis in large-scale seawater treatment.

Crossflow filtration

Reverse osmosis uses crossflow filtration to continuously sweep the membrane surface, reducing fouling and enhancing water recovery, while evaporator desalination relies on phase change without crossflow dynamics.

Total dissolved solids (TDS)

Reverse osmosis effectively reduces Total Dissolved Solids (TDS) levels up to 99%, while evaporators remove TDS by phase change but typically consume more energy and require handling of concentrated brine.

reverse osmosis vs evaporator desalination Infographic

njnir.com

njnir.com