Diesel-electric propulsion offers superior flexibility and efficiency in marine engineering by using diesel engines to generate electricity that powers electric motors, enabling smoother speed control and reduced mechanical complexity. Direct diesel drive systems transfer mechanical power straight from the diesel engine to the propeller, resulting in higher mechanical efficiency but less operational flexibility. Diesel-electric systems excel in applications requiring variable speed and precise maneuvering, while direct diesel drives are preferred for straightforward, high-torque demands.

Table of Comparison

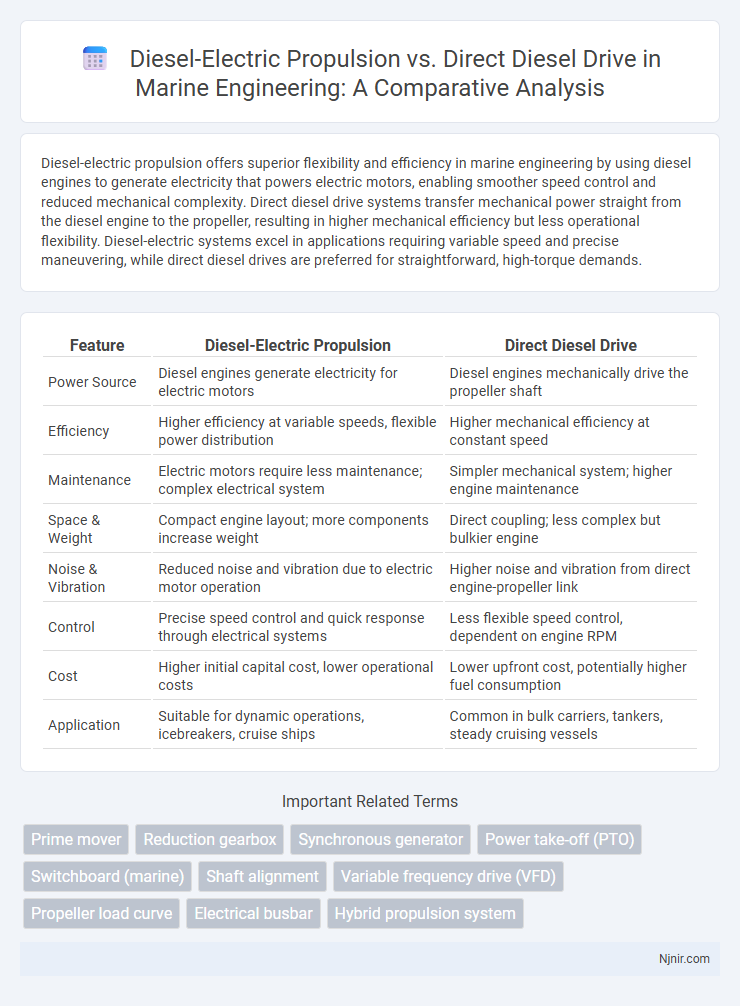

| Feature | Diesel-Electric Propulsion | Direct Diesel Drive |

|---|---|---|

| Power Source | Diesel engines generate electricity for electric motors | Diesel engines mechanically drive the propeller shaft |

| Efficiency | Higher efficiency at variable speeds, flexible power distribution | Higher mechanical efficiency at constant speed |

| Maintenance | Electric motors require less maintenance; complex electrical system | Simpler mechanical system; higher engine maintenance |

| Space & Weight | Compact engine layout; more components increase weight | Direct coupling; less complex but bulkier engine |

| Noise & Vibration | Reduced noise and vibration due to electric motor operation | Higher noise and vibration from direct engine-propeller link |

| Control | Precise speed control and quick response through electrical systems | Less flexible speed control, dependent on engine RPM |

| Cost | Higher initial capital cost, lower operational costs | Lower upfront cost, potentially higher fuel consumption |

| Application | Suitable for dynamic operations, icebreakers, cruise ships | Common in bulk carriers, tankers, steady cruising vessels |

Overview of Diesel-Electric Propulsion Systems

Diesel-electric propulsion systems integrate diesel engines with electric generators and motors, enabling efficient power distribution and flexible control in marine and rail applications. These systems offer improved fuel economy and reduced emissions compared to direct diesel drives by optimizing engine load and allowing for energy recovery through regenerative braking. Widely utilized in modern vessels and locomotives, diesel-electric propulsion enhances operational efficiency and overall performance while minimizing environmental impact.

Understanding Direct Diesel Drive Systems

Direct diesel drive systems connect the diesel engine directly to the propeller shaft, optimizing mechanical efficiency by eliminating intermediate components like generators or electric motors. This setup reduces energy losses, lowers maintenance costs, and offers straightforward control for vessels requiring consistent speed and power output. Diesel-electric propulsion, in contrast, converts mechanical energy into electrical energy to drive electric motors, providing greater flexibility in power distribution but at the expense of higher complexity and efficiency losses.

Efficiency Comparison: Diesel-Electric vs Direct Diesel

Diesel-electric propulsion systems offer higher operational efficiency by optimizing engine load and allowing variable speed control, which reduces fuel consumption during low-speed operations compared to direct diesel drive systems that deliver mechanical power directly to the propeller. The flexibility of diesel-electric setups supports improved energy management and lower emissions, especially in marine and rail applications where fluctuating power demands are common. Direct diesel drive systems maintain simplicity and lower initial costs but often experience reduced efficiency under partial loads due to fixed engine speed operation.

Flexibility and Vessel Design Considerations

Diesel-electric propulsion offers enhanced flexibility by decoupling engine operation from propeller speed, allowing for optimized power distribution and more efficient fuel consumption, especially in vessels requiring varied operating profiles such as cruise ships and offshore platforms. Direct diesel drive systems provide a simpler, more compact arrangement with fewer components but limit vessel design due to fixed engine placement and direct shaft alignment, constraining optimal space utilization and reducing maneuverability options. Vessel design using diesel-electric systems benefits from modular engine placement, facilitating better weight distribution and enabling advanced control systems that improve overall performance and adaptability across diverse maritime applications.

Fuel Consumption and Emissions Impact

Diesel-electric propulsion systems optimize fuel consumption by running diesel engines at constant, efficient speeds while electric motors handle variable loads, resulting in lower overall fuel use compared to direct diesel drive systems that operate engines under fluctuating loads. This steady engine operation significantly reduces emissions of nitrogen oxides (NOx) and particulate matter (PM), contributing to cleaner exhaust profiles in maritime and rail applications. In contrast, direct diesel drive systems experience higher fuel consumption and increased emissions due to engine speed variations and less efficient load management.

Maintenance Requirements and Lifecycle Costs

Diesel-electric propulsion systems typically have higher initial installation costs but offer reduced maintenance requirements due to fewer mechanical components exposed to wear and vibration, leading to lower lifecycle costs over time. Direct diesel drive systems involve more frequent maintenance because of the continuous mechanical coupling between the diesel engine and the drive shaft, increasing downtime and repair expenses. Lifecycle cost analysis often favors diesel-electric propulsion in applications requiring variable speed and load conditions, where efficiency gains offset maintenance savings.

Noise and Vibration Reduction

Diesel-electric propulsion systems significantly reduce noise and vibration by isolating the diesel engine from the propeller shaft through electric motors, resulting in smoother and quieter operation. Direct diesel drive transmits engine vibrations directly to the hull, leading to higher noise levels and increased structural vibrations. Noise and vibration reduction in diesel-electric systems enhances crew comfort and lowers acoustic signature, crucial for naval and research vessels.

Space Utilization and Installation Complexity

Diesel-electric propulsion offers superior space utilization by allowing flexible placement of engines and electric components independently, optimizing internal vessel layout and reducing vibrations. Direct diesel drive requires alignment of engines with the propulsion shaft, leading to more rigid and space-consuming installations. The installation complexity is higher for direct diesel drives due to precise mechanical alignment and integration, whereas diesel-electric systems benefit from modular components and simplified connection interfaces.

Applications in Modern Marine Vessels

Diesel-electric propulsion systems are widely used in cruise ships and research vessels for their improved fuel efficiency, reduced emissions, and flexible power distribution to multiple electric motors. Direct diesel drive remains prevalent in cargo ships and smaller commercial vessels where simplicity, lower initial costs, and mechanical reliability are prioritized. Modern marine applications increasingly favor diesel-electric systems for hybrid configurations and integration with renewable energy sources, enhancing operational versatility.

Future Trends in Marine Propulsion Technologies

Diesel-electric propulsion offers enhanced fuel efficiency and reduced emissions by optimizing engine loading through electric power distribution, making it suitable for future marine vessels aiming for sustainability. Direct diesel drive systems boast simplicity and lower initial costs but face challenges in meeting stringent environmental regulations and achieving fuel flexibility. Emerging trends favor hybrid systems integrating battery storage and alternative fuels to improve energy efficiency, reduce carbon footprints, and comply with evolving maritime emission standards.

Prime mover

Diesel-electric propulsion uses a diesel engine as a prime mover to generate electricity for electric motors, offering flexible power distribution and efficiency, while direct diesel drive connects the diesel engine directly to the propulsion shaft for simpler mechanics but less operational flexibility.

Reduction gearbox

Diesel-electric propulsion eliminates the need for a reduction gearbox by using electric motors to control propeller speed, whereas direct diesel drive requires a reduction gearbox to match the engine's high RPM to the propeller's optimal speed.

Synchronous generator

Diesel-electric propulsion systems utilize synchronous generators to convert mechanical energy from diesel engines into stable, variable-frequency electrical power, enabling precise control and improved efficiency compared to direct diesel drives which mechanically link engines directly to the propeller.

Power take-off (PTO)

Diesel-electric propulsion offers greater flexibility and efficiency in Power Take-Off (PTO) applications by enabling variable speed and load management compared to the fixed-speed PTO typical of direct diesel drive systems.

Switchboard (marine)

Diesel-electric propulsion systems use a marine switchboard to efficiently manage power distribution between diesel generators and electric motors, offering greater flexibility and redundancy compared to the simpler switchboards in direct diesel drive systems.

Shaft alignment

Diesel-electric propulsion offers enhanced shaft alignment flexibility compared to direct diesel drive systems, reducing mechanical stress and improving overall system reliability.

Variable frequency drive (VFD)

Variable frequency drive (VFD) technology enhances diesel-electric propulsion systems by optimizing motor speed control, improving fuel efficiency, and reducing emissions compared to traditional direct diesel drive configurations.

Propeller load curve

Diesel-electric propulsion systems optimize propeller load curves by enabling variable speed and torque control, whereas direct diesel drive systems face rigid load curves due to fixed engine-propeller coupling.

Electrical busbar

Diesel-electric propulsion offers enhanced operational flexibility and simplified power distribution through the use of an electrical busbar, unlike direct diesel drive systems that lack centralized electrical power management.

Hybrid propulsion system

Hybrid propulsion systems combine diesel-electric and direct diesel drive technologies to optimize fuel efficiency, reduce emissions, and enhance operational flexibility in marine and industrial applications.

Diesel-electric propulsion vs direct diesel drive Infographic

njnir.com

njnir.com