Dynamic positioning systems enable vessels to maintain a precise position and heading using thrusters and GPS technology, enhancing operational efficiency in deep water and harsh environments. Anchoring relies on physical anchors dropped to the seabed, providing stability in shallower waters but limiting mobility and depth range. Choosing between dynamic positioning and anchoring depends on factors such as water depth, seabed conditions, and operational requirements.

Table of Comparison

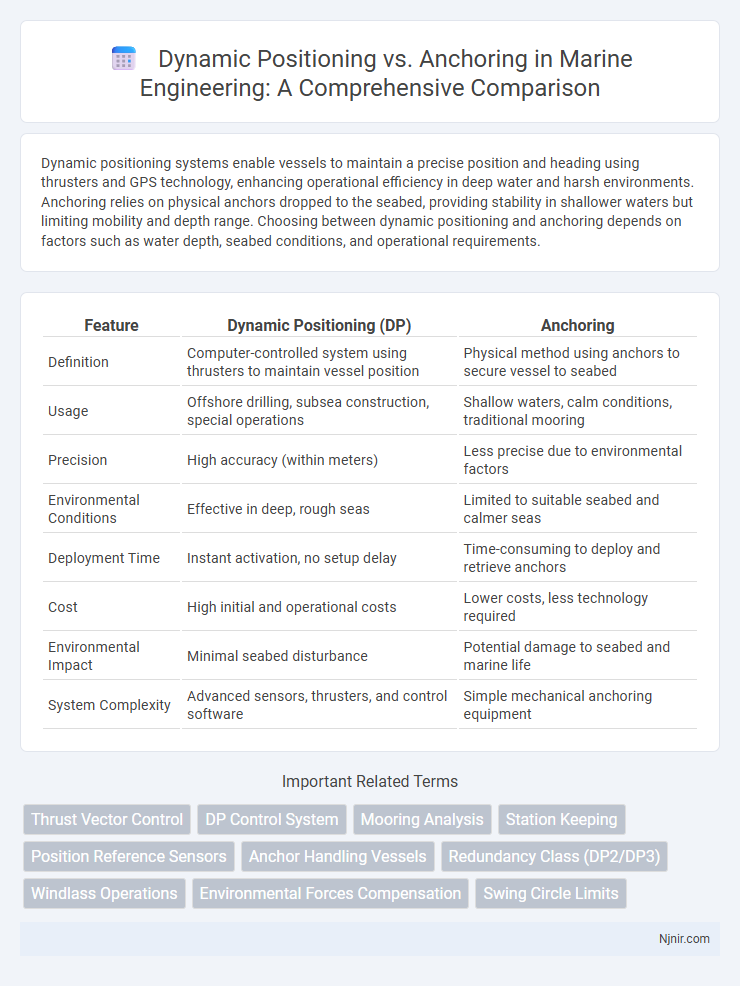

| Feature | Dynamic Positioning (DP) | Anchoring |

|---|---|---|

| Definition | Computer-controlled system using thrusters to maintain vessel position | Physical method using anchors to secure vessel to seabed |

| Usage | Offshore drilling, subsea construction, special operations | Shallow waters, calm conditions, traditional mooring |

| Precision | High accuracy (within meters) | Less precise due to environmental factors |

| Environmental Conditions | Effective in deep, rough seas | Limited to suitable seabed and calmer seas |

| Deployment Time | Instant activation, no setup delay | Time-consuming to deploy and retrieve anchors |

| Cost | High initial and operational costs | Lower costs, less technology required |

| Environmental Impact | Minimal seabed disturbance | Potential damage to seabed and marine life |

| System Complexity | Advanced sensors, thrusters, and control software | Simple mechanical anchoring equipment |

Introduction to Dynamic Positioning and Anchoring

Dynamic Positioning (DP) is an advanced navigation system that uses computer-controlled thrusters to maintain a vessel's position and heading automatically, crucial for operations where precise station-keeping is required, such as offshore drilling and diving support. Anchoring relies on deploying a physical anchor to secure a vessel in place, depending on seabed conditions and suitable depth, often used for cost-effective stationary positioning in shallower waters. The choice between DP and anchoring depends on operational demands, environmental conditions, and vessel capabilities, balancing precision and practicality.

Fundamentals of Dynamic Positioning Systems

Dynamic positioning systems use computer-controlled thrusters and sensors to maintain a vessel's position and heading automatically, without relying on anchors. These systems integrate GPS, wind sensors, motion sensors, and gyrocompasses to continuously calculate the necessary adjustments, ensuring stability in challenging marine environments. Unlike anchoring, dynamic positioning allows for precise station-keeping in deep water or sensitive areas where anchoring is impractical or environmentally harmful.

Core Principles of Anchoring Techniques

Anchoring relies on mechanical means such as chains, ropes, and seabed interaction to secure a vessel, emphasizing holding power through weight and friction. Dynamic Positioning (DP) uses thrusters and propellers controlled by computer systems to maintain vessel position without physical connection to the seabed. Anchoring techniques prioritize seabed type, anchor design, scope length, and environmental conditions to optimize stability and minimize drag.

Operational Advantages of Dynamic Positioning

Dynamic Positioning (DP) systems provide superior operational precision by automatically maintaining a vessel's position and heading using thrusters and propellers, eliminating the need for physical anchors. This capability enhances operational safety and efficiency, especially in deep waters or sensitive environments where anchoring is impractical or damaging. DP enables continuous adjustments to environmental changes such as wind, current, and waves, allowing uninterrupted operations like drilling, diving, or construction.

Limitations and Challenges of Anchoring

Anchoring faces significant limitations such as dependency on seabed conditions, making it ineffective in rocky, uneven, or environmentally sensitive areas. The process requires manual intervention and continuous monitoring to avoid anchor drag, especially under strong currents, waves, or high winds. These challenges increase operational risks, reduce precision in vessel positioning, and limit the use of anchoring in deepwater or dynamic offshore environments.

Safety Considerations: DP vs Anchoring

Dynamic Positioning (DP) systems enhance vessel safety by using thrusters and sensors to maintain position without physical anchors, reducing risks of anchor dragging and seabed damage. Anchoring, while reliable in shallow waters, poses hazards such as anchor line breakage and environmental impact on fragile marine habitats. DP offers superior safety in deep waters and congested areas, minimizing collision risk and ensuring operational stability under adverse weather conditions.

Environmental Impact Comparison

Dynamic positioning (DP) systems minimize seabed disturbance by using thrusters to maintain vessel position without physical contact, significantly reducing habitat damage compared to traditional anchoring methods. Anchoring causes physical harm to marine ecosystems by dragging and embedding anchors and chains into the seabed, disrupting benthic organisms and coral reefs. The reduced environmental footprint of DP systems supports sustainable marine operations, especially in ecologically sensitive areas.

Cost Implications and Operational Efficiency

Dynamic positioning systems incur higher upfront costs due to advanced sensors, thrusters, and control systems, but reduce operational expenses by minimizing anchor damage and seabed disturbance. Anchoring requires lower initial investment but can lead to increased costs from equipment wear, manual labor, and environmental impact mitigation. Operational efficiency improves with dynamic positioning through precise station-keeping, reducing downtime and enhancing safety in complex offshore operations.

Application Scenarios in Marine Engineering

Dynamic Positioning (DP) systems enable vessels to maintain precise locations using thrusters and propellers, ideal for deepwater drilling units, offshore construction, and subsea operations where anchoring is impractical. Anchoring remains preferred for shallow water scenarios with stable seabeds, such as coastal supply vessels, fishing boats, and stationary platforms that require cost-effective, reliable station-keeping without electronic intervention. Marine engineering projects select DP for complex, high-precision tasks and anchoring for simpler, routine applications to balance operational efficiency and environmental conditions.

Future Trends and Technological Innovations

Dynamic Positioning (DP) systems are rapidly advancing with integration of AI-driven algorithms and real-time sensor fusion, enhancing vessel stability and operational precision in challenging marine environments. Future trends emphasize autonomous DP operations powered by machine learning, reducing human error and improving fuel efficiency compared to traditional anchoring methods. Innovations such as hybrid propulsion systems and advanced thruster designs further optimize dynamic positioning, promoting safer and more sustainable offshore activities.

Thrust Vector Control

Thrust vector control in dynamic positioning systems enables precise vessel maneuvering by adjusting thruster angles dynamically, whereas anchoring relies on fixed position maintenance with physical anchors and lacks real-time thrust adjustments.

DP Control System

Dynamic Positioning (DP) control systems use real-time sensor data and advanced algorithms to automatically maintain a vessel's position and heading without physical anchors, offering precise maneuverability and operational efficiency over traditional anchoring methods.

Mooring Analysis

Dynamic Positioning systems enhance mooring analysis by providing real-time vessel station-keeping without reliance on anchors, improving precision and operational flexibility in challenging marine environments.

Station Keeping

Dynamic Positioning uses automated thrusters and sensors to maintain a vessel's station with high precision, whereas Anchoring relies on physical anchors to keep the vessel stationary, often less effective in deep or unstable seabeds.

Position Reference Sensors

Dynamic positioning relies on advanced position reference sensors such as DGPS, taut wire, and acoustic beacons to maintain vessel location, while anchoring depends on physical anchor engagement with seabed without requiring position sensors.

Anchor Handling Vessels

Anchor Handling Vessels utilize dynamic positioning systems to maintain precise station-keeping during offshore operations, offering enhanced safety and efficiency compared to traditional anchoring methods.

Redundancy Class (DP2/DP3)

Dynamic Positioning systems with Redundancy Class DP2 or DP3 offer enhanced reliability and fault tolerance compared to traditional anchoring by maintaining position through multiple independent control and power systems.

Windlass Operations

Dynamic positioning systems eliminate reliance on windlass operations by maintaining vessel position through automated thruster control, whereas anchoring depends on manual windlass deployment to secure the vessel against environmental forces.

Environmental Forces Compensation

Dynamic Positioning systems continuously compensate for environmental forces such as wind, waves, and currents through thruster adjustments, whereas traditional anchoring relies on physical anchors to resist these forces passively.

Swing Circle Limits

Dynamic positioning maintains vessel stability within strict swing circle limits by actively adjusting thrusters, whereas anchoring relies on physical anchor scope and chain length to control swing radius.

Dynamic Positioning vs Anchoring Infographic

njnir.com

njnir.com