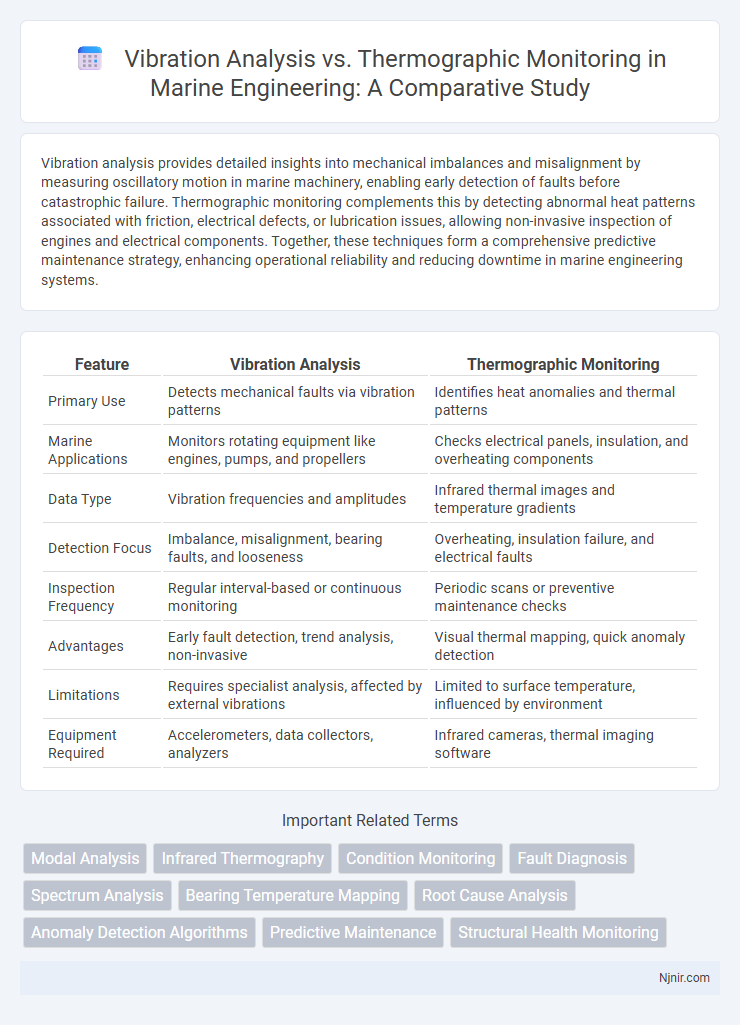

Vibration analysis provides detailed insights into mechanical imbalances and misalignment by measuring oscillatory motion in marine machinery, enabling early detection of faults before catastrophic failure. Thermographic monitoring complements this by detecting abnormal heat patterns associated with friction, electrical defects, or lubrication issues, allowing non-invasive inspection of engines and electrical components. Together, these techniques form a comprehensive predictive maintenance strategy, enhancing operational reliability and reducing downtime in marine engineering systems.

Table of Comparison

| Feature | Vibration Analysis | Thermographic Monitoring |

|---|---|---|

| Primary Use | Detects mechanical faults via vibration patterns | Identifies heat anomalies and thermal patterns |

| Marine Applications | Monitors rotating equipment like engines, pumps, and propellers | Checks electrical panels, insulation, and overheating components |

| Data Type | Vibration frequencies and amplitudes | Infrared thermal images and temperature gradients |

| Detection Focus | Imbalance, misalignment, bearing faults, and looseness | Overheating, insulation failure, and electrical faults |

| Inspection Frequency | Regular interval-based or continuous monitoring | Periodic scans or preventive maintenance checks |

| Advantages | Early fault detection, trend analysis, non-invasive | Visual thermal mapping, quick anomaly detection |

| Limitations | Requires specialist analysis, affected by external vibrations | Limited to surface temperature, influenced by environment |

| Equipment Required | Accelerometers, data collectors, analyzers | Infrared cameras, thermal imaging software |

Introduction to Vibration Analysis and Thermographic Monitoring

Vibration analysis detects mechanical faults by measuring oscillations in machinery components, enabling early identification of imbalance, misalignment, or bearing failures. Thermographic monitoring uses infrared imaging to capture temperature variations, revealing overheating issues and electrical anomalies in equipment. Both techniques provide complementary data for predictive maintenance, enhancing asset reliability and reducing unplanned downtime.

Key Principles of Vibration Analysis in Marine Engineering

Vibration analysis in marine engineering centers on measuring oscillations in machinery to detect imbalances, misalignments, and bearing faults, which can prevent catastrophic equipment failures. It involves capturing frequency and amplitude data through sensors like accelerometers to identify characteristic vibration patterns associated with specific mechanical issues. Compared to thermographic monitoring, which detects temperature anomalies indicating overheating or insulation problems, vibration analysis provides early-stage fault detection by analyzing dynamic mechanical behavior of marine engines and rotating equipment.

Fundamentals of Thermographic Monitoring on Marine Vessels

Thermographic monitoring on marine vessels involves infrared imaging to detect temperature variations indicating potential equipment failures, such as overheating bearings or electrical faults. Unlike vibration analysis, which measures mechanical oscillations to predict anomalies, thermography provides a non-contact assessment of thermal anomalies critical for preventive maintenance. This technique enhances safety and operational efficiency by enabling early detection of thermal issues in engines, generators, and electrical panels aboard ships.

Common Applications: Vibration Analysis vs Thermography

Vibration analysis is commonly applied in rotating equipment such as motors, pumps, and gearboxes to detect imbalances, misalignments, and bearing faults early. Thermographic monitoring is primarily used for electrical inspections, identifying overheating components in switchgear, busbars, and circuit breakers to prevent failures. Both techniques complement each other in predictive maintenance programs by targeting different failure modes across mechanical and electrical systems.

Advantages of Vibration Analysis for Marine Equipment

Vibration analysis offers precise fault detection in marine equipment by identifying imbalances, misalignments, and bearing failures early, reducing unexpected downtime and costly repairs. It provides continuous, real-time monitoring of rotating machinery, enabling proactive maintenance strategies that enhance operational efficiency. Compared to thermographic monitoring, vibration analysis excels in detecting mechanical issues before they manifest as temperature changes, ensuring higher reliability in harsh marine environments.

Benefits of Thermographic Monitoring in Marine Machinery

Thermographic monitoring in marine machinery enables early detection of overheating components, preventing costly equipment failures and reducing downtime. It provides real-time visual data for maintenance teams to identify insulation breakdowns, electrical faults, and bearing issues without physical contact. This non-intrusive method enhances safety, extends machinery lifespan, and improves overall operational efficiency compared to vibration analysis alone.

Limitations and Challenges: Vibration Analysis vs Thermography

Vibration analysis faces challenges in detecting early-stage faults in slow-moving equipment and requires baseline data for accurate interpretation, limiting its effectiveness in complex machinery. Thermographic monitoring struggles with surface-only temperature detection, often missing subsurface defects and being affected by external environmental factors like ambient temperature variations. Both methods demand skilled interpretation and can generate false positives if not calibrated properly, highlighting the need for complementary use to improve reliability in predictive maintenance.

Data Interpretation and Diagnostic Accuracy

Vibration analysis provides detailed insights into mechanical faults through frequency spectrum data, enabling precise identification of imbalance, misalignment, and bearing defects. Thermographic monitoring offers visual data on temperature anomalies, which is effective for detecting electrical faults, insulation failures, and overheating components. Combining both methods enhances diagnostic accuracy by correlating mechanical vibrations with thermal patterns for comprehensive equipment condition assessment.

Integrating Vibration and Thermographic Monitoring Strategies

Integrating vibration analysis and thermographic monitoring strategies enhances predictive maintenance by combining real-time mechanical fault detection with thermal anomaly identification, resulting in a comprehensive assessment of equipment health. This dual-approach enables early detection of issues such as imbalance, misalignment, bearing defects, and overheating, reducing unplanned downtime and maintenance costs. Optimized data fusion from both vibration and thermal sensors improves diagnostic accuracy, leading to more informed decision-making in asset management systems.

Future Trends in Marine Condition Monitoring Technologies

Future trends in marine condition monitoring technologies emphasize the integration of advanced vibration analysis with thermographic monitoring to enhance predictive maintenance accuracy. The adoption of IoT-enabled sensors and AI-driven analytics enables real-time data fusion from vibration signatures and thermal imaging, facilitating early fault detection in marine engines and propulsion systems. Enhanced machine learning algorithms and edge computing are expected to optimize energy efficiency and reduce downtime by providing more precise diagnostics and proactive intervention strategies.

Modal Analysis

Modal analysis enhances vibration analysis by identifying natural frequencies and mode shapes, enabling more precise detection of structural anomalies compared to thermographic monitoring.

Infrared Thermography

Infrared thermography provides non-contact, real-time monitoring of temperature variations in equipment, enabling early detection of faults often missed by vibration analysis.

Condition Monitoring

Vibration analysis detects mechanical faults through oscillation patterns, while thermographic monitoring identifies thermal anomalies, both essential for comprehensive condition monitoring in predictive maintenance.

Fault Diagnosis

Vibration analysis detects mechanical faults through abnormal oscillations, while thermographic monitoring identifies thermal anomalies for precise fault diagnosis in equipment maintenance.

Spectrum Analysis

Spectrum analysis in vibration analysis provides detailed frequency data to identify mechanical faults, whereas thermographic monitoring detects thermal anomalies indicating potential equipment failures.

Bearing Temperature Mapping

Bearing Temperature Mapping using thermographic monitoring provides precise thermal profiles that complement vibration analysis by detecting early-stage bearing defects and overheating risks.

Root Cause Analysis

Vibration analysis excels at detecting mechanical faults such as misalignment and imbalance, while thermographic monitoring identifies thermal anomalies, making both complementary tools for comprehensive root cause analysis in predictive maintenance.

Anomaly Detection Algorithms

Anomaly detection algorithms in vibration analysis primarily identify mechanical faults through signal frequency and amplitude variations, while thermographic monitoring uses thermal pattern deviations for early heat-related fault detection.

Predictive Maintenance

Vibration analysis detects mechanical faults through abnormal oscillations while thermographic monitoring identifies heat anomalies, both enabling predictive maintenance by forecasting equipment failures and minimizing downtime.

Structural Health Monitoring

Vibration analysis detects structural anomalies by measuring dynamic response frequencies, while thermographic monitoring identifies defects through infrared temperature variations, both integral techniques for comprehensive Structural Health Monitoring.

vibration analysis vs thermographic monitoring Infographic

njnir.com

njnir.com