Shaft alignment ensures that the rotating shafts in marine engines are correctly positioned to minimize wear and prevent vibration, improving overall system efficiency. Shaft balancing focuses on distributing mass evenly around the shaft to reduce centrifugal forces that cause vibration and mechanical stress. Proper shaft alignment combined with precise shaft balancing enhances the reliability and longevity of marine propulsion systems.

Table of Comparison

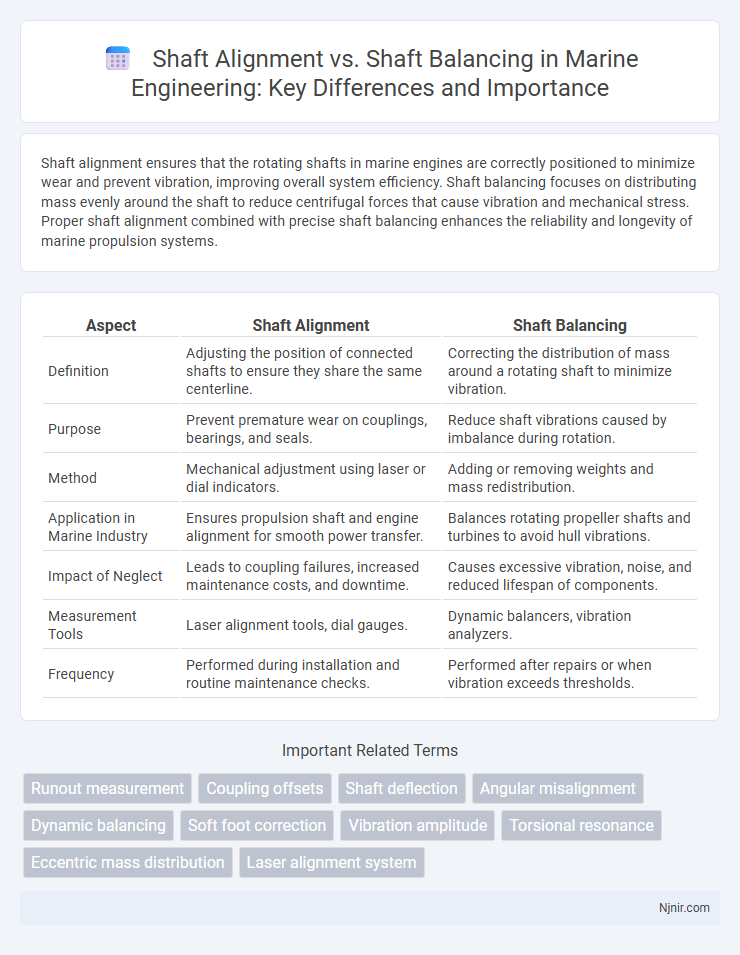

| Aspect | Shaft Alignment | Shaft Balancing |

|---|---|---|

| Definition | Adjusting the position of connected shafts to ensure they share the same centerline. | Correcting the distribution of mass around a rotating shaft to minimize vibration. |

| Purpose | Prevent premature wear on couplings, bearings, and seals. | Reduce shaft vibrations caused by imbalance during rotation. |

| Method | Mechanical adjustment using laser or dial indicators. | Adding or removing weights and mass redistribution. |

| Application in Marine Industry | Ensures propulsion shaft and engine alignment for smooth power transfer. | Balances rotating propeller shafts and turbines to avoid hull vibrations. |

| Impact of Neglect | Leads to coupling failures, increased maintenance costs, and downtime. | Causes excessive vibration, noise, and reduced lifespan of components. |

| Measurement Tools | Laser alignment tools, dial gauges. | Dynamic balancers, vibration analyzers. |

| Frequency | Performed during installation and routine maintenance checks. | Performed after repairs or when vibration exceeds thresholds. |

Introduction to Shaft Alignment and Shaft Balancing

Shaft alignment ensures the proper positioning of two rotating shafts to minimize wear and vibration, critical in maintaining machinery efficiency and prolonging equipment life. Shaft balancing involves correcting weight distribution in rotating components to prevent excessive vibration and damage during operation. Both processes are essential for optimal performance and reliability of rotating machinery in industries such as manufacturing, power generation, and petrochemical.

Importance in Marine Engineering

Shaft alignment ensures precise positioning between the engine and propeller shaft, minimizing vibration and wear to extend the lifespan of marine propulsion systems. Shaft balancing reduces dynamic imbalances in rotating components, preventing excessive shaft stress and improving fuel efficiency in vessels. Proper implementation of both techniques is critical in marine engineering to maintain operational reliability, reduce maintenance costs, and enhance overall vessel performance.

Definitions: Shaft Alignment vs Shaft Balancing

Shaft alignment involves precisely adjusting the position of connected shafts to ensure their rotational axes are collinear, preventing excessive vibration and wear. Shaft balancing, on the other hand, corrects uneven mass distribution in a rotating shaft to minimize centrifugal forces that cause vibration. Both processes are critical in maintaining machinery performance, but alignment focuses on angular and parallel shaft positioning while balancing targets mass distribution.

Causes of Misalignment and Imbalance

Shaft misalignment primarily results from improper installation, thermal expansion, or foundation settling, causing excessive vibration and premature bearing wear. Imbalance occurs due to uneven mass distribution from manufacturing defects, material buildup, or component wear, leading to rotor vibration and increased stress on machinery. Both conditions significantly affect equipment reliability and energy efficiency, necessitating regular maintenance and precise corrective measures.

Effects on Marine Propulsion Systems

Shaft alignment ensures the precise connection between the engine and propeller shaft, reducing vibration and preventing premature wear of marine propulsion components. Shaft balancing corrects mass distribution along the rotating shaft, minimizing dynamic imbalance that causes excessive vibration and noise in marine vessels. Proper alignment and balancing together enhance propulsion efficiency, extend equipment lifespan, and improve overall vessel performance.

Alignment Procedures in Marine Vessels

Shaft alignment in marine vessels involves precise alignment of the propeller shaft with the engine and gearbox to minimize vibrations and prevent premature bearing wear. Procedures include soft foot correction, laser alignment using dial indicators, and thermal growth compensation to ensure optimal angular and parallel alignment within strict tolerances. Accurate shaft alignment improves fuel efficiency, reduces noise, and extends the lifespan of marine propulsion systems compared to shaft balancing, which focuses on counteracting rotational imbalance through weight adjustments.

Balancing Techniques for Marine Shafts

Balancing techniques for marine shafts primarily involve static and dynamic balancing to reduce vibration and prevent premature wear in propulsion systems. Static balancing ensures even weight distribution when the shaft is stationary, while dynamic balancing corrects imbalances during rotation by adjusting weights on the shaft or coupling elements. Proper shaft balancing enhances marine vessel efficiency, reduces fuel consumption, and extends the lifespan of bearings and seals.

Diagnostic Tools and Technologies

Shaft alignment relies heavily on laser alignment systems and dial indicators to precisely measure angular and parallel misalignments between coupled shafts, ensuring optimal machine performance and reduced wear. Shaft balancing employs vibration analyzers and dynamic balancing machines to detect and correct imbalance by measuring oscillations caused by uneven mass distribution, preventing excessive vibration and premature bearing failure. Advanced diagnostic tools integrate real-time monitoring and data analytics, enabling predictive maintenance and enhancing the accuracy of both alignment and balancing processes.

Maintenance Best Practices

Shaft alignment ensures precision positioning of rotating components to reduce wear, vibration, and energy loss, which is critical for maintaining optimal machinery performance. Shaft balancing corrects mass distribution in rotating parts to minimize vibration, prevent bearing damage, and extend equipment lifespan. Implementing regular shaft alignment and balancing as part of maintenance schedules enhances reliability, reduces downtime, and lowers repair costs in industrial machinery operations.

Operational Consequences of Neglect

Neglecting shaft alignment can lead to increased vibration, premature bearing failure, and excessive wear on couplings, resulting in costly equipment downtime. Ignoring shaft balancing causes uneven rotational forces, leading to shaft fatigue, noisy operation, and potential catastrophic failure of rotating machinery. Both misalignment and imbalance reduce overall operational efficiency and significantly increase maintenance expenses.

Runout measurement

Runout measurement in shaft alignment detects misalignment-induced shaft deviation, while in shaft balancing it quantifies mass distribution irregularities causing vibration.

Coupling offsets

Coupling offsets in shaft alignment directly impact equipment performance by causing misalignment-induced vibrations, whereas shaft balancing primarily addresses mass distribution to reduce rotational imbalance without correcting coupling misalignment.

Shaft deflection

Shaft alignment minimizes shaft deflection by ensuring components are collinear, while shaft balancing reduces deflection caused by unbalanced rotational forces.

Angular misalignment

Angular misalignment in shaft alignment causes uneven stress and premature wear, whereas shaft balancing primarily addresses dynamic imbalance to reduce vibration without correcting angular deviations.

Dynamic balancing

Dynamic balancing corrects rotor imbalances by adjusting mass distribution during shaft operation, whereas shaft alignment ensures proper positioning of connected shafts to prevent vibration and wear.

Soft foot correction

Soft foot correction is essential in shaft alignment to eliminate frame distortion that can cause misalignment, whereas shaft balancing focuses on reducing vibrations by distributing mass evenly on the rotating shaft.

Vibration amplitude

Shaft alignment reduces vibration amplitude caused by misaligned shafts, while shaft balancing minimizes vibration amplitude by correcting mass distribution imbalances.

Torsional resonance

Shaft alignment prevents misalignment-induced torsional resonance by maintaining proper angular positioning, while shaft balancing reduces torsional vibrations caused by mass imbalances in rotating components.

Eccentric mass distribution

Shaft balancing corrects eccentric mass distribution to reduce vibration, while shaft alignment ensures proper axial positioning of connected shafts for optimal performance.

Laser alignment system

Laser alignment systems precisely align rotating shafts to reduce vibration and wear, whereas shaft balancing corrects mass distribution to minimize imbalance and operational noise.

shaft alignment vs shaft balancing Infographic

njnir.com

njnir.com