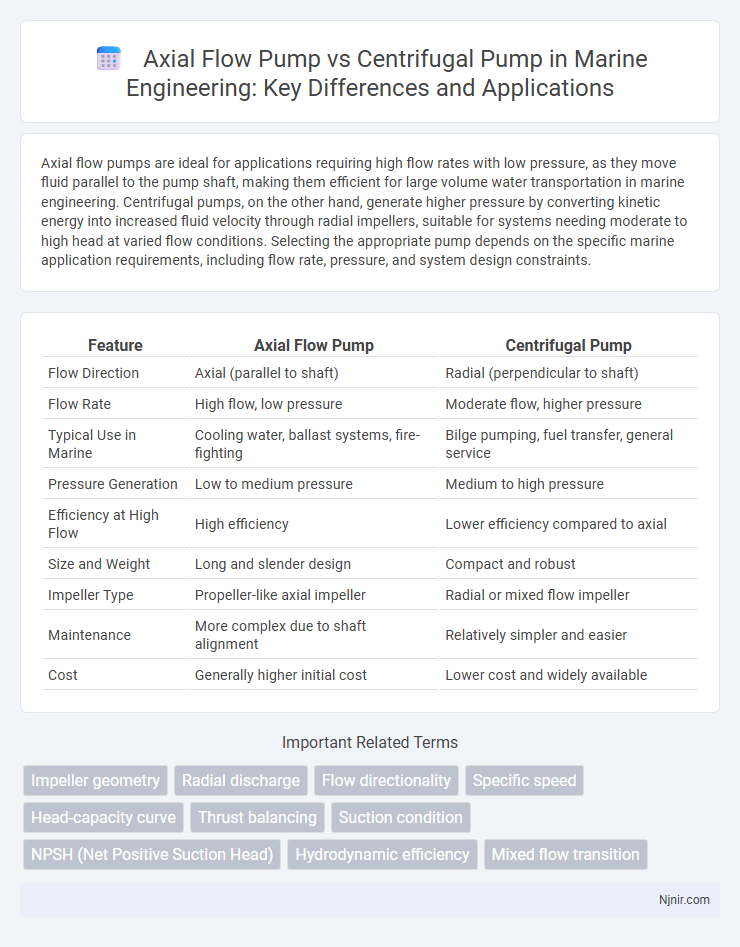

Axial flow pumps are ideal for applications requiring high flow rates with low pressure, as they move fluid parallel to the pump shaft, making them efficient for large volume water transportation in marine engineering. Centrifugal pumps, on the other hand, generate higher pressure by converting kinetic energy into increased fluid velocity through radial impellers, suitable for systems needing moderate to high head at varied flow conditions. Selecting the appropriate pump depends on the specific marine application requirements, including flow rate, pressure, and system design constraints.

Table of Comparison

| Feature | Axial Flow Pump | Centrifugal Pump |

|---|---|---|

| Flow Direction | Axial (parallel to shaft) | Radial (perpendicular to shaft) |

| Flow Rate | High flow, low pressure | Moderate flow, higher pressure |

| Typical Use in Marine | Cooling water, ballast systems, fire-fighting | Bilge pumping, fuel transfer, general service |

| Pressure Generation | Low to medium pressure | Medium to high pressure |

| Efficiency at High Flow | High efficiency | Lower efficiency compared to axial |

| Size and Weight | Long and slender design | Compact and robust |

| Impeller Type | Propeller-like axial impeller | Radial or mixed flow impeller |

| Maintenance | More complex due to shaft alignment | Relatively simpler and easier |

| Cost | Generally higher initial cost | Lower cost and widely available |

Introduction to Axial Flow and Centrifugal Pumps in Marine Engineering

Axial flow pumps and centrifugal pumps are essential in marine engineering for fluid movement and propulsion systems. Axial flow pumps generate flow parallel to the pump shaft, offering high flow rates with low pressure, making them ideal for applications like ballast and fire-fighting systems. Centrifugal pumps use radial flow to convert kinetic energy into pressure, providing higher pressure output suitable for cooling systems and bilge pumping in ships.

Working Principles of Axial Flow Pumps

Axial flow pumps operate by using propeller-like impellers to push fluid along the pump shaft's axis, generating high flow rates with relatively low pressure. The impeller blades create a linear flow pattern, moving fluid efficiently in applications requiring large volumes at low heads. This design contrasts with centrifugal pumps, which rely on radial flow and centrifugal force to increase fluid pressure through a rotating impeller.

Operating Mechanism of Centrifugal Pumps

Centrifugal pumps operate by converting rotational kinetic energy from an impeller into hydrodynamic energy, which moves fluid outward from the pump's center through centrifugal force. The impeller spins, creating a low-pressure area at the intake, drawing fluid in and accelerating it radially outward to the pump casing, where the velocity energy converts to pressure energy. This mechanism enables centrifugal pumps to handle high flow rates efficiently, making them suitable for applications requiring continuous and steady fluid movement.

Key Design Differences: Axial Flow vs Centrifugal Pumps

Axial flow pumps feature propeller-like impellers that move fluid parallel to the pump shaft, enabling high flow rates at low pressure, while centrifugal pumps use a rotating impeller to generate radial flow, producing higher pressure at relatively lower flow rates. Axial flow pumps are designed with elongated, straight flow passages to minimize energy loss, contrasting with the curved volute or diffuser casings in centrifugal pumps that convert velocity into pressure efficiently. The distinct hydraulic designs impact their applications, with axial flow pumps ideal for irrigation and circulation, whereas centrifugal pumps excel in water supply and industrial processes requiring significant pressure.

Performance Characteristics in Marine Applications

Axial flow pumps deliver high flow rates at low pressure, making them ideal for marine applications requiring efficient water circulation and ballast operations. Centrifugal pumps generate higher pressure at comparatively lower flow rates, suitable for firefighting systems and bilge water removal on ships. Performance efficiency varies with application demands, where axial flow pumps excel in continuous, large-volume discharge, and centrifugal pumps provide reliable pressure for targeted fluid movement.

Efficiency Comparison: Axial Flow and Centrifugal Pumps

Axial flow pumps generally exhibit higher efficiency at low to medium head applications due to their ability to handle large volumes of fluid with minimal energy loss. Centrifugal pumps tend to be more efficient at higher heads and lower flow rates because their design facilitates greater pressure increase per stage. Efficiency variations between axial flow and centrifugal pumps depend largely on the specific hydraulic conditions and system requirements, making pump selection critical for optimizing energy consumption.

Common Uses on Ships and Offshore Platforms

Axial flow pumps are commonly used on ships and offshore platforms for applications requiring high flow rates at low pressures, such as cooling water circulation and ballast water transfer. Centrifugal pumps, in contrast, are favored for their versatility and efficiency in handling a wide range of liquids, making them ideal for fuel oil transfer, bilge pumping, and fire-fighting systems on marine vessels. Both pump types are essential for maintaining operational safety and efficiency in maritime and offshore environments.

Advantages and Limitations of Each Pump Type

Axial flow pumps excel in moving large volumes of fluid at low pressure, making them ideal for applications such as flood control and irrigation; however, they have limited head capabilities compared to centrifugal pumps. Centrifugal pumps deliver higher pressure and better efficiency for pumping fluids at moderate to high heads but are less effective in handling very high flow rates or low head conditions. The choice between axial flow and centrifugal pumps depends on specific operational requirements like flow rate, pressure, and fluid characteristics.

Maintenance and Reliability Considerations

Axial flow pumps typically require more frequent maintenance due to their complex blade adjustments and susceptibility to wear from solid particles, whereas centrifugal pumps offer higher reliability with simpler designs and fewer moving parts. Maintenance of axial flow pumps emphasizes blade inspection, alignment, and clearance checks, while centrifugal pumps focus on seal integrity, bearing lubrication, and impeller condition. Reliability in centrifugal pumps often translates to longer operational cycles and reduced downtime, making them favorable in applications demanding consistent performance.

Selection Criteria for Marine Systems

Axial flow pumps are selected for marine systems requiring high flow rates at low head, making them ideal for ballast water circulation and cooling applications. Centrifugal pumps are preferred when moderate flow and higher pressure head are necessary, such as in fire fighting systems and bilge pumping. Selection criteria emphasize the pump's flow capacity, head requirements, space constraints, and energy efficiency for optimal marine system performance.

Impeller geometry

Axial flow pumps feature elongated, propeller-like impellers designed for high flow and low head applications, while centrifugal pumps use radially oriented impellers optimized for high pressure and moderate flow.

Radial discharge

Axial flow pumps discharge fluid parallel to the pump shaft, resulting in minimal radial discharge compared to centrifugal pumps that expel fluid radially outward from the impeller.

Flow directionality

Axial flow pumps move fluid parallel to the pump shaft, providing high flow rates with low pressure, whereas centrifugal pumps direct fluid perpendicular to the shaft, generating higher pressure at lower flow rates.

Specific speed

Axial flow pumps have a higher specific speed (typically above 5000) suitable for high flow, low head applications, whereas centrifugal pumps exhibit lower specific speeds (usually between 500 and 3000) optimized for moderate flow and higher head scenarios.

Head-capacity curve

Axial flow pumps exhibit a relatively flat head-capacity curve with minimal head variation across changing flow rates, whereas centrifugal pumps show a steeply declining head-capacity curve indicating significant head drop as flow increases.

Thrust balancing

Axial flow pumps feature thrust balancing through the use of balance drums or grooves to counteract axial thrust, whereas centrifugal pumps often rely on balance holes or double-suction impellers to manage thrust forces effectively.

Suction condition

Axial flow pumps maintain stable performance under low NPSH (Net Positive Suction Head) conditions compared to centrifugal pumps, making them more suitable for applications with limited suction pressure.

NPSH (Net Positive Suction Head)

Axial flow pumps generally require lower Net Positive Suction Head (NPSH) than centrifugal pumps due to their design, making them more suitable for applications with low inlet pressure and high flow rates.

Hydrodynamic efficiency

Axial flow pumps exhibit higher hydrodynamic efficiency than centrifugal pumps at low head and high flow conditions due to their streamlined blade design minimizing energy losses.

Mixed flow transition

Mixed flow pumps combine axial and centrifugal pump characteristics, offering higher flow rates like axial flow pumps while generating moderate head similar to centrifugal pumps, making them ideal for applications requiring a balance between flow and pressure.

axial flow pump vs centrifugal pump Infographic

njnir.com

njnir.com