UMS (Unmanned Machinery Space) notation allows marine vessels to operate engine rooms without constant human presence, relying on automated monitoring and alarm systems to ensure safety and efficiency. This reduces the need for continuous crew supervision, lowering labor costs and minimizing human error compared to manned engine rooms. However, manned engine rooms offer immediate manual intervention, making them suitable for older ships or operations requiring direct human oversight.

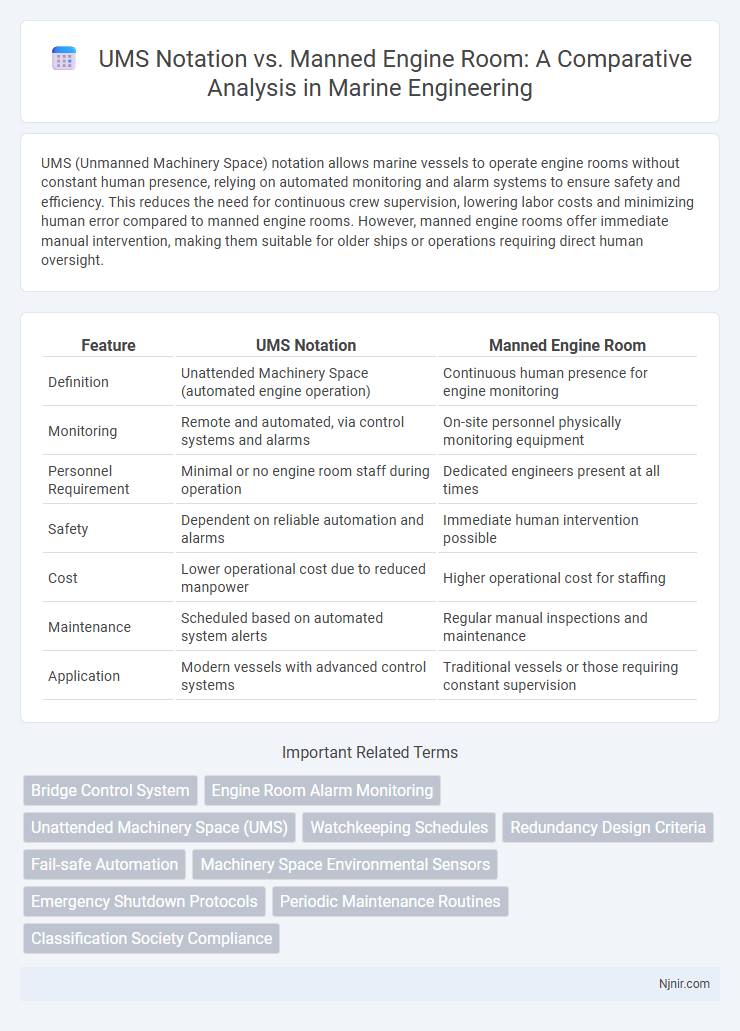

Table of Comparison

| Feature | UMS Notation | Manned Engine Room |

|---|---|---|

| Definition | Unattended Machinery Space (automated engine operation) | Continuous human presence for engine monitoring |

| Monitoring | Remote and automated, via control systems and alarms | On-site personnel physically monitoring equipment |

| Personnel Requirement | Minimal or no engine room staff during operation | Dedicated engineers present at all times |

| Safety | Dependent on reliable automation and alarms | Immediate human intervention possible |

| Cost | Lower operational cost due to reduced manpower | Higher operational cost for staffing |

| Maintenance | Scheduled based on automated system alerts | Regular manual inspections and maintenance |

| Application | Modern vessels with advanced control systems | Traditional vessels or those requiring constant supervision |

Introduction to UMS Notation and Manned Engine Rooms

UMS notation refers to Unattended Machinery Space, indicating engine rooms equipped with automated systems allowing for remote monitoring and control, significantly reducing the need for continuous manned presence. Manned engine rooms require onboard personnel to operate and supervise machinery systems directly, ensuring real-time response to operational changes and emergencies. The transition from manned engine rooms to UMS notation enhances operational efficiency and safety through advanced automation and alarm systems.

Defining Unattended Machinery Space (UMS) Notation

Unattended Machinery Space (UMS) notation refers to a classification indicating that the engine room can operate safely without continuous human presence, supported by automated monitoring and alarm systems. This system enables remote supervision from the ship's bridge or control room, reducing the need for manned engine watchkeepers during normal operations. UMS notation requires strict compliance with international regulations and equipment standards to ensure machinery safety and immediate fault detection.

Characteristics of Manned Engine Rooms

Manned engine rooms require continuous crew presence to monitor machinery, ensuring real-time troubleshooting and maintenance, which enhances operational safety and reliability. These spaces are equipped with comprehensive manual control panels and alarms to facilitate immediate human intervention in case of anomalies. The staffing demands and higher operational costs distinguish manned engine rooms from UMS (Unattended Machinery Space) notations, which rely on automated monitoring systems.

Regulatory Requirements for UMS and Manned Operations

UMS (Unmanned Machinery Space) notation requires compliance with stringent regulatory standards such as SOLAS Chapter II-2 and guidelines from the IMO, mandating advanced remote monitoring and alarm systems to ensure safety without continuous onboard engineering personnel. Manned engine room operations must adhere to traditional regulations that emphasize the presence of qualified engineers for direct supervision and immediate intervention, as outlined by classification societies like ABS and DNV. Both operational types require regular audits and certifications to validate adherence to safety protocols and environmental regulations, but UMS notation allows for reduced staffing while maintaining strict compliance through automated control and monitoring technologies.

Key Technological Differences between UMS and Manned Engine Rooms

UMS (Unattended Machinery Space) notation relies on advanced automation systems, remote monitoring, and alarm technologies that enable engine rooms to operate without constant human presence, contrasting with the traditional manned engine rooms requiring continuous manual supervision. Key technological differences include the integration of sophisticated sensors, control systems, and fail-safe mechanisms in UMS to detect and address abnormalities autonomously, whereas manned engine rooms depend heavily on direct human intervention for monitoring and troubleshooting. Enhanced communication networks and centralized control consoles in UMS notation facilitate real-time data analysis and decision-making, improving efficiency and safety compared to the conventional manual operations in manned engine rooms.

Operational Efficiency: UMS vs Manned Engine Rooms

UMS (Unmanned Machinery Space) notation significantly enhances operational efficiency by reducing the need for continuous human presence, allowing remote monitoring and automated controls in engine rooms. Manned engine rooms require constant staffing, which increases labor costs and limits operational flexibility during off-peak hours. The integration of advanced sensors and alarm systems in UMS setups minimizes downtime and enables quicker response to anomalies, optimizing fuel consumption and maintenance schedules.

Safety and Risk Assessment in UMS and Manned Engine Rooms

UMS (Unattended Machinery Space) notation requires comprehensive automation and remote monitoring systems, significantly reducing human presence in engine rooms and thereby decreasing the risk of human error-related accidents. Safety protocols in UMS focus heavily on real-time alarms, automatic shutdowns, and redundant control systems to mitigate risks associated with unattended operations. In contrast, manned engine rooms rely on continuous human supervision, enabling immediate intervention but increasing exposure to hazards such as fires, toxic leaks, and mechanical failures, thus necessitating stringent personal protective measures and risk assessments.

Crew Competency and Training Implications

UMS notation requires crew members to possess advanced competencies in automated systems management, necessitating specialized training in remote monitoring and fault diagnosis for safe engine room operations. In contrast, manned engine rooms rely heavily on traditional hands-on experience and real-time decision-making skills, demanding comprehensive mechanical and operational training for constant on-site supervision. Transitioning to UMS notation shifts training focus towards automation technology, system integration, and emergency response protocols specific to unattended machinery spaces.

Maintenance Practices: Scheduled vs Condition-Based

UMS notation allows for condition-based maintenance in engine rooms, enabling real-time monitoring of equipment status and predictive interventions, reducing unexpected failures and downtime. In contrast, manned engine rooms typically rely on scheduled maintenance practices, following fixed intervals regardless of actual equipment condition, which can lead to either premature part replacement or increased risk of breakdowns. Condition-based maintenance in UMS environments optimizes resource allocation and enhances safety by addressing issues precisely when needed, unlike the more rigid, time-dependent approach in manned operations.

Future Trends in Marine Engineering Automation

UMS (Unmanned Machinery Space) notation significantly enhances operational efficiency by enabling remote monitoring and control of engine rooms, reducing the need for constant onboard personnel. Future trends in marine engineering automation emphasize integration of AI-powered predictive maintenance, advanced sensor networks, and real-time data analytics to further optimize engine performance and safety. The shift toward fully autonomous ships and smart engine rooms is driven by innovations in IoT, machine learning, and robust cybersecurity measures to ensure reliable manned engine room alternatives.

Bridge Control System

UMS notation enables unmanned engine room operation through advanced Bridge Control Systems that provide remote monitoring, automated alerts, and real-time engine management, enhancing safety and operational efficiency compared to traditional manned engine rooms.

Engine Room Alarm Monitoring

UMS notation enables unattended Engine Room Alarm Monitoring with automated alerts and remote diagnostics, enhancing safety and operational efficiency compared to traditional manned engine rooms.

Unattended Machinery Space (UMS)

Unattended Machinery Space (UMS) notation allows engine rooms to operate without continuous human supervision by employing advanced monitoring and alarm systems, enhancing efficiency compared to traditional manned engine rooms.

Watchkeeping Schedules

UMS notation mandates automated monitoring systems enabling reduced watchkeeping schedules with unattended machinery spaces, whereas manned engine rooms require continuous personnel presence for watchkeeping and operational oversight.

Redundancy Design Criteria

UMS notation mandates rigorous redundancy design criteria in manned engine rooms, requiring separate power sources, duplicated control systems, and fail-safe mechanisms to ensure continuous safe operation without onboard personnel.

Fail-safe Automation

UMS notation integrates fail-safe automation systems in unmanned engine rooms to enhance operational safety by enabling remote monitoring and automatic fault detection compared to traditional manned engine room setups.

Machinery Space Environmental Sensors

UMS notation requires advanced Machinery Space Environmental Sensors for continuous monitoring and automated safety control, enhancing operational efficiency compared to traditional manned engine rooms.

Emergency Shutdown Protocols

UMS notation requires automated Emergency Shutdown Protocols with remote monitoring and control systems, while manned engine rooms rely on manual shutdown procedures performed by on-site personnel.

Periodic Maintenance Routines

UMS notation streamlines Periodic Maintenance Routines by enabling remote monitoring and automated diagnostics, whereas manned engine rooms rely on manual checks and direct human intervention for maintenance tasks.

Classification Society Compliance

UMS notation requires strict adherence to Classification Society Compliance standards involving automated machinery monitoring, remote control capabilities, and enhanced safety protocols unlike traditional manned engine rooms.

UMS notation vs manned engine room Infographic

njnir.com

njnir.com