Marine engines and marine motors differ primarily in their function and design; marine engines convert fuel into mechanical energy through combustion, typically used for larger vessels requiring significant power. Marine motors, often electric, utilize electrical energy to generate motion with higher efficiency and lower emissions, suitable for smaller boats or hybrid systems. Understanding the specific application and power requirements is crucial for selecting the appropriate marine propulsion system.

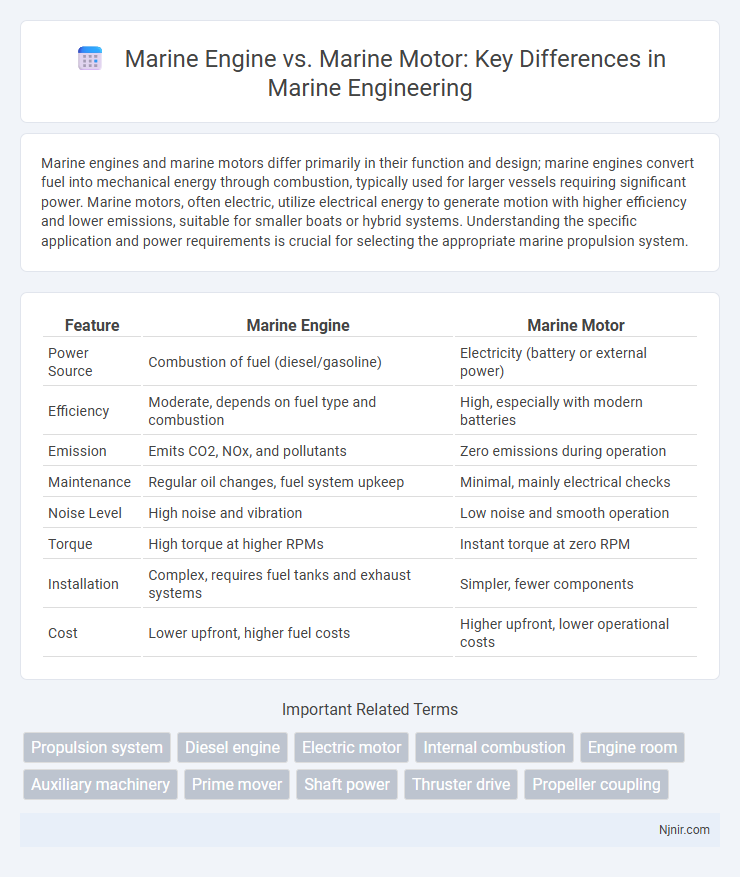

Table of Comparison

| Feature | Marine Engine | Marine Motor |

|---|---|---|

| Power Source | Combustion of fuel (diesel/gasoline) | Electricity (battery or external power) |

| Efficiency | Moderate, depends on fuel type and combustion | High, especially with modern batteries |

| Emission | Emits CO2, NOx, and pollutants | Zero emissions during operation |

| Maintenance | Regular oil changes, fuel system upkeep | Minimal, mainly electrical checks |

| Noise Level | High noise and vibration | Low noise and smooth operation |

| Torque | High torque at higher RPMs | Instant torque at zero RPM |

| Installation | Complex, requires fuel tanks and exhaust systems | Simpler, fewer components |

| Cost | Lower upfront, higher fuel costs | Higher upfront, lower operational costs |

Introduction to Marine Engines and Marine Motors

Marine engines and marine motors are critical propulsion systems used in various types of vessels, with marine engines typically referring to internal combustion engines powered by diesel or gasoline, and marine motors often indicating electric propulsion units. Diesel marine engines dominate commercial shipping due to their high power output and fuel efficiency, while marine motors are increasingly popular in recreational boats for their quiet operation and environmental benefits. Understanding the distinctions between these propulsion methods is essential for selecting the appropriate system based on vessel size, usage, and environmental regulations.

Core Differences Between Marine Engines and Marine Motors

Marine engines and marine motors serve distinct functions in maritime propulsion systems, with marine engines typically referring to internal combustion units that generate power through fuel combustion, while marine motors often denote electric motors converting electrical energy into mechanical motion. The core differences lie in their energy sources, with marine engines running on diesel or gasoline and marine motors powered by batteries or external electrical supply, impacting efficiency, maintenance, and emissions. Understanding these distinctions is crucial for selecting the appropriate propulsion method based on vessel size, usage, and environmental considerations.

Types of Marine Engines: Internal Combustion and Beyond

Marine engines primarily include internal combustion types such as diesel and gasoline engines, which are widely used for their efficiency and power output in boats and ships. Beyond internal combustion, alternatives like electric marine motors and hybrid propulsion systems are gaining popularity due to their reduced emissions and improved fuel economy. Advances in technology continue to expand options with fuel cell engines and renewable energy-powered motors enhancing the marine propulsion landscape.

Types of Marine Motors: Electric and Hydraulic Solutions

Marine motors primarily include electric and hydraulic types, each designed to meet specific marine propulsion and auxiliary needs. Electric marine motors offer high efficiency, low noise, and minimal emissions, making them ideal for eco-friendly vessels and applications requiring precise control, while hydraulic marine motors provide robust power density and durability suitable for heavy-duty marine equipment and steering systems. Selecting between electric and hydraulic solutions depends on operational requirements, vessel size, and environmental considerations within marine engineering.

Performance Comparison: Power, Efficiency, and Speed

Marine engines typically deliver higher power output and torque compared to marine motors, making them suitable for larger vessels requiring significant thrust. Marine motors, especially electric variants, offer superior energy efficiency and quieter operation, enhancing fuel economy and reducing emissions. Speed performance depends on vessel design, but marine engines generally enable higher maximum speeds, while marine motors excel in consistent, efficient cruising conditions.

Applications: Where Marine Engines and Motors Excel

Marine engines excel in heavy-duty applications such as cargo ships, commercial fishing vessels, and large yachts due to their robust power output and fuel efficiency for long-distance travel. Marine motors are ideal for small boats, recreational watercraft, and electric-driven vessels, offering quiet operation and environmental benefits in coastal and inland waterways. Both technologies play crucial roles in marine transportation, with engines dominating traditional propulsion and motors advancing eco-friendly marine mobility.

Maintenance Requirements and Lifecycle

Marine engines typically require regular oil changes, filter replacements, and cooling system inspections to ensure optimal performance, with maintenance intervals varying based on engine type and usage. Marine motors, especially electric types, demand less frequent mechanical servicing but require battery health monitoring and electrical system checks to maintain efficiency. The lifecycle of marine engines averages 15,000 to 20,000 operational hours, while marine motors often exceed 20,000 hours, benefiting from fewer moving parts and lower wear rates.

Environmental Impact and Emission Considerations

Marine engines and marine motors differ significantly in environmental impact and emission considerations. Marine engines, typically internal combustion engines, emit higher levels of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter, contributing to marine pollution and greenhouse gas effects. In contrast, electric marine motors produce zero direct emissions, reducing carbon footprint and supporting stricter maritime environmental regulations such as IMO Tier III standards.

Cost Analysis: Acquisition, Operation, and Maintenance

Marine engines typically have higher acquisition costs compared to marine motors due to their complexity and power output capabilities. Operational expenses for marine engines are generally greater, driven by higher fuel consumption and more extensive cooling systems, whereas marine motors benefit from greater energy efficiency and lower fuel usage. Maintenance costs for marine engines involve frequent servicing of internal combustion components, while marine motors demand less frequent, simpler upkeep, resulting in overall reduced lifetime expenses.

Future Trends in Marine Propulsion Technologies

Future trends in marine propulsion technologies emphasize the shift from traditional marine engines, typically diesel-powered, to electric marine motors driven by advancements in battery energy density and power electronics. The integration of hybrid systems combining internal combustion engines with electric motors is gaining traction for enhanced fuel efficiency and reduced emissions. Innovations in hydrogen fuel cells and renewable energy sources are accelerating the development of zero-emission marine vessels, shaping the future landscape of sustainable marine propulsion.

Propulsion system

Marine engines, typically combustion-based, provide higher power and torque for large vessel propulsion systems, while marine motors, primarily electric, offer efficient, low-maintenance propulsion ideal for smaller or hybrid marine applications.

Diesel engine

Marine diesel engines provide higher fuel efficiency, greater torque, and longer durability compared to electric marine motors, making them the preferred choice for heavy-duty maritime applications.

Electric motor

Electric marine motors offer higher efficiency, lower emissions, and reduced maintenance compared to traditional marine engines, making them ideal for sustainable and eco-friendly maritime propulsion.

Internal combustion

Marine engines, specifically internal combustion types, convert fuel into mechanical power through controlled explosions, whereas marine motors typically refer to electric propulsion systems powered by batteries or external sources.

Engine room

Marine engines in the engine room provide high torque and durability for propulsion, while marine motors offer compact size and efficient electric power for auxiliary systems.

Auxiliary machinery

Marine engines typically power primary propulsion, while marine motors are commonly used in auxiliary machinery such as pumps, generators, and winches for enhanced vessel operation.

Prime mover

A marine engine serves as the primary prime mover by converting fuel into mechanical power to propel vessels, while a marine motor typically refers to an electric or hydraulic device that drives propulsion systems using external power sources.

Shaft power

Marine engines typically deliver higher shaft power than marine motors, making them more suitable for large vessels requiring robust propulsion systems.

Thruster drive

Thruster drives in marine engines provide enhanced torque and fuel efficiency compared to marine motors, making them ideal for precise maneuvering and propulsion in marine vessels.

Propeller coupling

Marine engines typically require specialized propeller couplings for torque transmission, while marine motors often use integrated coupling designs for direct drive efficiency.

marine engine vs marine motor Infographic

njnir.com

njnir.com