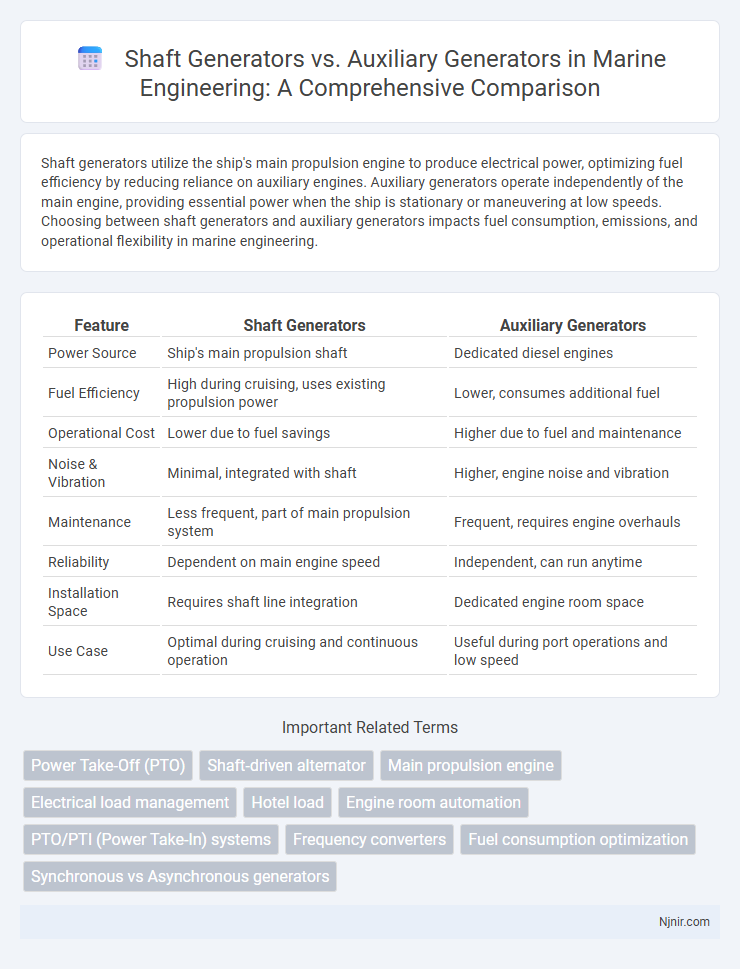

Shaft generators utilize the ship's main propulsion engine to produce electrical power, optimizing fuel efficiency by reducing reliance on auxiliary engines. Auxiliary generators operate independently of the main engine, providing essential power when the ship is stationary or maneuvering at low speeds. Choosing between shaft generators and auxiliary generators impacts fuel consumption, emissions, and operational flexibility in marine engineering.

Table of Comparison

| Feature | Shaft Generators | Auxiliary Generators |

|---|---|---|

| Power Source | Ship's main propulsion shaft | Dedicated diesel engines |

| Fuel Efficiency | High during cruising, uses existing propulsion power | Lower, consumes additional fuel |

| Operational Cost | Lower due to fuel savings | Higher due to fuel and maintenance |

| Noise & Vibration | Minimal, integrated with shaft | Higher, engine noise and vibration |

| Maintenance | Less frequent, part of main propulsion system | Frequent, requires engine overhauls |

| Reliability | Dependent on main engine speed | Independent, can run anytime |

| Installation Space | Requires shaft line integration | Dedicated engine room space |

| Use Case | Optimal during cruising and continuous operation | Useful during port operations and low speed |

Introduction to Marine Power Generation Systems

Shaft generators convert mechanical energy from the ship's main engine into electrical power, enhancing fuel efficiency by utilizing existing propulsion power instead of running separate engines. Auxiliary generators, powered by independent diesel engines, provide electrical power primarily when the main engine is not operational or during peak loads, ensuring continuous power supply. In marine power generation systems, balancing shaft and auxiliary generators optimizes energy consumption, reduces emissions, and maintains critical onboard electrical operations.

Overview of Shaft Generators in Marine Engineering

Shaft generators in marine engineering harness mechanical energy from the ship's main engine shaft to produce electrical power, offering efficient energy conversion and reduced fuel consumption compared to auxiliary generators. These generators are pivotal in large vessels, providing a primary source of electrical power during cruising by synchronizing with the propulsion system. Their integration minimizes reliance on auxiliary generators, leading to optimized operational costs and lower emissions in marine energy management.

Understanding Auxiliary Generators and Their Functions

Auxiliary generators provide essential power for shipboard systems when the main engine or shaft generator is offline, ensuring continuous operation of electrical equipment and safety systems. They function independently of the propulsion system, supplying electricity for lighting, navigation aids, and emergency systems, thus maintaining operational stability. Their ability to run on various fuels and operate under different load conditions makes auxiliary generators crucial for flexible and reliable onboard power management.

Efficiency Comparison: Shaft Generators vs Auxiliary Generators

Shaft generators deliver higher efficiency by directly converting mechanical energy from the ship's main engine into electrical power, reducing fuel consumption and emissions. Auxiliary generators typically operate on separate engines, resulting in lower overall efficiency due to additional fuel use and maintenance demands. Comparing fuel costs and power output reveals shaft generators provide a more sustainable and economical solution for onboard electricity generation.

Fuel Consumption and Operational Cost Analysis

Shaft generators directly utilize the main engine's mechanical power to produce electricity, resulting in lower fuel consumption compared to auxiliary generators, which rely on separate diesel engines. Reduced fuel use in shaft generators translates into significant operational cost savings, especially in vessels with high electrical demand during cruising. Auxiliary generators offer flexibility for load management but incur higher fuel expenses and maintenance costs due to independent engine operation.

Technical Design Considerations

Shaft generators integrate directly with the ship's main engine shaft, offering efficient electrical power generation by converting mechanical energy during propulsion, which reduces fuel consumption and emissions. Auxiliary generators are independent units designed to provide electrical power when the main engine is off or insufficient, featuring flexible operational capacity but higher fuel usage. The technical design of shaft generators emphasizes robust coupling, vibration isolation, and synchronization with the engine speed, whereas auxiliary generators prioritize versatility, load adaptability, and compliance with emission regulations.

Environmental Impact and Emissions

Shaft generators utilize the ship's main engine power to produce electricity, resulting in lower fuel consumption and reduced greenhouse gas emissions compared to auxiliary generators that rely on separate diesel engines. Auxiliary generators typically emit higher levels of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter due to their independent operation and fuel usage. Utilizing shaft generators aligns with maritime emission regulations such as IMO Tier III, promoting sustainable shipping through decreased environmental impact.

Reliability and Maintenance Requirements

Shaft generators offer higher reliability due to their direct connection to the main engine shaft, resulting in fewer moving parts and reduced wear compared to auxiliary generators. Auxiliary generators, while versatile and easier to maintain independently, require more frequent maintenance because of complex mechanical and electrical components. The streamlined design of shaft generators minimizes downtime and maintenance costs, making them preferable for continuous power supply in marine and industrial applications.

Integration with Modern Ship Propulsion Systems

Shaft generators, directly coupled to the ship's main engine shaft, enable efficient energy recovery by converting mechanical power into electrical energy only when the propulsion system is operational, optimizing fuel consumption and reducing emissions. Auxiliary generators, independent from the main propulsion, provide electrical power at all times, offering flexibility for hotel loads and redundancy but less efficiency in fuel usage during cruising. Modern integrated ship propulsion systems often combine both types to balance energy efficiency with operational reliability, leveraging advanced power management systems to seamlessly switch or parallel the generators based on real-time electrical demand and propulsion status.

Future Trends and Technological Advancements in Marine Power Generation

Shaft generators and auxiliary generators are evolving through increased integration of hybrid systems and advanced power electronics to enhance efficiency and reduce emissions in marine vessels. Future trends emphasize the development of smarter control systems and energy storage solutions, enabling optimized load management and the seamless transition between shaft and auxiliary power modes. Emerging technologies such as permanent magnet motors and liquid-cooled converters promise significant improvements in weight, space savings, and overall system reliability for marine power generation.

Power Take-Off (PTO)

Shaft generators convert mechanical energy from the ship's main engine shaft into electrical power through Power Take-Off (PTO), while auxiliary generators rely on independent engines to generate electricity, providing flexibility during low-speed or shutdown conditions.

Shaft-driven alternator

Shaft-driven alternators convert mechanical energy from a ship's main engine into electrical power with higher efficiency and reduced fuel consumption compared to auxiliary generators that rely on separate diesel engines.

Main propulsion engine

Shaft generators convert mechanical energy from the main propulsion engine into electrical power, offering higher efficiency and reduced fuel consumption compared to auxiliary generators which run independently on separate diesel engines.

Electrical load management

Shaft generators optimize electrical load management by directly converting mechanical energy from the main engine into electricity, reducing fuel consumption compared to auxiliary generators that rely on separate engine-driven power sources primarily used during low-speed or docked operations.

Hotel load

Shaft generators efficiently supply hotel load power during vessel operation by utilizing main engine rotation, whereas auxiliary generators provide hotel load power primarily during port stays or main engine shutdowns.

Engine room automation

Shaft generators enhance engine room automation by directly converting engine power into electrical energy for onboard systems, improving efficiency and reducing fuel consumption compared to auxiliary generators that rely on separate engines and require additional monitoring and control.

PTO/PTI (Power Take-In) systems

Shaft generators provide mechanical power converted from the main engine to generate electricity while auxiliary generators supply electrical power independently, with PTO/PTI systems enabling flexible energy management by allowing power to be taken-in from or fed back into the propulsion shaft for hybrid vessel operation.

Frequency converters

Shaft generators directly convert mechanical energy from the ship's engine into electrical power with stable frequency output, while auxiliary generators rely on frequency converters to regulate variable engine speeds and maintain consistent electrical frequency for onboard systems.

Fuel consumption optimization

Shaft generators optimize fuel consumption by converting mechanical energy from the main engine into electricity, reducing reliance on auxiliary generators that burn additional fuel.

Synchronous vs Asynchronous generators

Shaft generators are typically synchronous generators providing stable voltage and frequency for shipboard power systems, while auxiliary generators are often asynchronous (induction) types used for supplementary power with simpler design and lower maintenance.

Shaft generators vs Auxiliary generators Infographic

njnir.com

njnir.com