Smart ballast systems in marine engineering offer enhanced precision and adaptability compared to traditional ballast automation by leveraging real-time data analytics and IoT integration to optimize vessel stability and fuel efficiency. These advanced systems reduce human error and maintenance costs through automated monitoring and adaptive control of water levels, improving overall safety during navigation. Traditional ballast automation relies on fixed programming and manual input, limiting responsiveness to changing sea conditions and reducing operational efficiency.

Table of Comparison

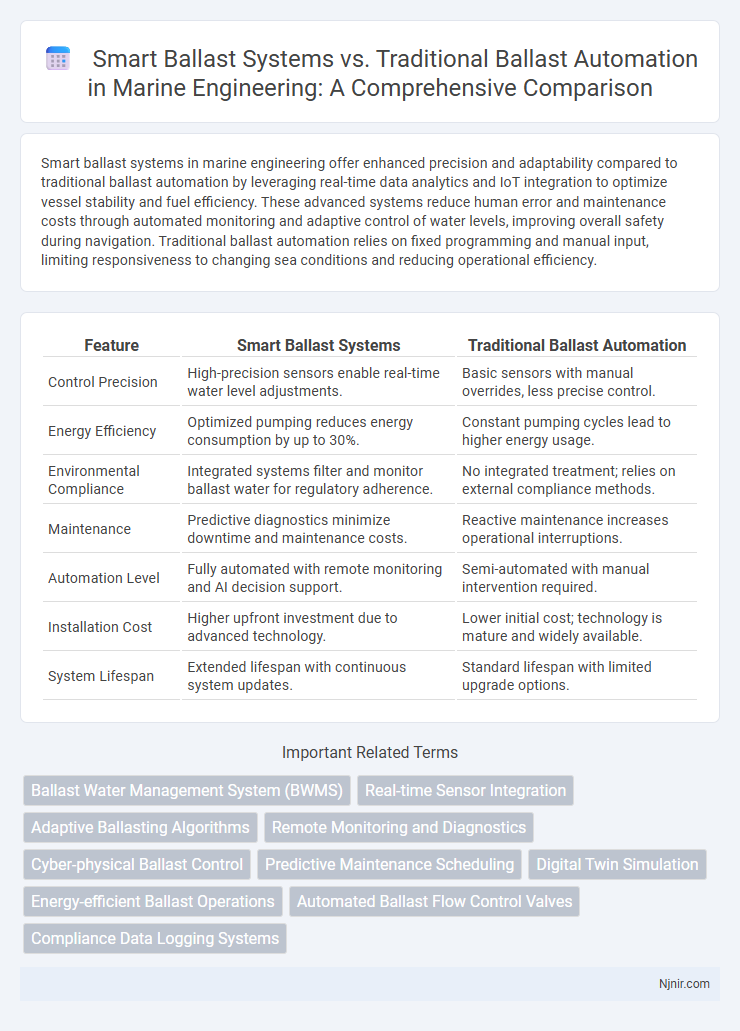

| Feature | Smart Ballast Systems | Traditional Ballast Automation |

|---|---|---|

| Control Precision | High-precision sensors enable real-time water level adjustments. | Basic sensors with manual overrides, less precise control. |

| Energy Efficiency | Optimized pumping reduces energy consumption by up to 30%. | Constant pumping cycles lead to higher energy usage. |

| Environmental Compliance | Integrated systems filter and monitor ballast water for regulatory adherence. | No integrated treatment; relies on external compliance methods. |

| Maintenance | Predictive diagnostics minimize downtime and maintenance costs. | Reactive maintenance increases operational interruptions. |

| Automation Level | Fully automated with remote monitoring and AI decision support. | Semi-automated with manual intervention required. |

| Installation Cost | Higher upfront investment due to advanced technology. | Lower initial cost; technology is mature and widely available. |

| System Lifespan | Extended lifespan with continuous system updates. | Standard lifespan with limited upgrade options. |

Introduction to Ballast Systems in Marine Engineering

Smart ballast systems in marine engineering utilize advanced sensors and automated controls to optimize water ballast management, enhancing ship stability and fuel efficiency while reducing human error. Traditional ballast automation relies on manual operation and fixed control schemes, which often result in less precise water level adjustments and increased energy consumption. Integration of real-time data analytics and IoT in smart ballast systems revolutionizes ballast water management by providing adaptive responses to changing sea conditions and regulatory compliance requirements.

Evolution of Ballast Automation: Traditional to Smart Systems

Smart ballast systems represent a significant evolution from traditional ballast automation by integrating advanced sensors, real-time data analytics, and automated control algorithms. Unlike conventional systems that rely on manual adjustments and simple control mechanisms, smart ballasts optimize water levels and weight distribution dynamically to enhance vessel stability and fuel efficiency. The transition to smart systems enables predictive maintenance and remote monitoring, reducing operational costs and improving overall maritime safety.

Key Components of Traditional Ballast Automation

Traditional ballast automation relies on key components such as electromechanical relays, basic sensors for water level and pressure, and manual control panels for operation. These systems typically use fixed-timing circuits and simple feedback loops to regulate ballast tank filling and emptying, resulting in limited adaptability and precision. The essential parts include pumps, limit switches, float sensors, and centralized control units, which together provide basic automation without advanced diagnostics or remote monitoring.

Technology Behind Smart Ballast Systems

Smart ballast systems utilize advanced digital sensors and microcontrollers to dynamically regulate lamp voltage and current, enhancing energy efficiency and prolonging lamp life. Unlike traditional ballast automation relying on fixed magnetic or analog electronic components, smart ballasts employ integrated communication protocols for real-time monitoring and adaptive control. These cutting-edge technologies enable precise power modulation, fault detection, and remote management, optimizing lighting performance in modern applications.

Operational Efficiency: Smart vs Traditional Ballast Systems

Smart ballast systems enhance operational efficiency by utilizing real-time data and automated adjustments to maintain optimal vessel stability, significantly reducing fuel consumption and ballast water management costs. Traditional ballast automation often relies on fixed schedules and manual inputs, leading to inefficiencies and increased risk of compliance issues with environmental regulations. The integration of advanced sensors and AI in smart systems enables precise control and adaptive responses, outperforming traditional methods in both energy savings and operational reliability.

Compliance with Environmental Regulations

Smart ballast systems enhance compliance with environmental regulations by incorporating advanced sensors and real-time monitoring that reduce harmful emissions and optimize energy consumption. These systems automatically adjust ballast levels to minimize ballast water discharge impact, adhering strictly to International Maritime Organization (IMO) standards. Traditional ballast automation lacks such precise control, often resulting in higher operational inefficiencies and increased risk of regulatory non-compliance.

Cost Implications and ROI Analysis

Smart ballast systems offer significant cost savings compared to traditional ballast automation through enhanced energy efficiency, reduced maintenance expenses, and extended lamp life. ROI analysis indicates that smart ballasts deliver faster payback periods due to lower operational costs and improved system reliability, often achieving cost recovery within 1 to 3 years. The initial higher investment in smart ballast technology is offset by long-term financial benefits, making them a more economical choice for lighting control in commercial and industrial environments.

Maintenance and Reliability Considerations

Smart ballast systems offer enhanced maintenance through real-time monitoring, predictive diagnostics, and remote troubleshooting, significantly reducing downtime compared to traditional ballast automation. The integration of IoT sensors and advanced analytics in smart ballasts allows for early detection of faults, extending operational lifespan and improving reliability. Traditional systems typically require more frequent manual inspections and exhibit higher failure rates due to limited diagnostic capabilities and reactive maintenance approaches.

Integration with Shipboard Digitalization

Smart ballast systems integrate seamlessly with shipboard digitalization platforms by utilizing IoT sensors and advanced analytics to provide real-time monitoring and control of ballast water operations. Unlike traditional ballast automation, which operates independently with limited data exchange, smart systems enable centralized management through digital interfaces, enhancing operational efficiency and regulatory compliance. This integration supports predictive maintenance and data-driven decision-making, crucial for modern maritime asset management.

Future Trends in Ballast System Automation

Smart ballast systems integrate IoT sensors and AI-driven analytics to optimize ballast water management, offering real-time monitoring and enhanced compliance with environmental regulations. Traditional ballast automation relies on fixed schedules and manual controls, limiting efficiency and adaptability in dynamic maritime conditions. Future trends emphasize increased use of predictive maintenance, digital twin technology, and blockchain-based data security to improve operational reliability and regulatory transparency in ballast system automation.

Ballast Water Management System (BWMS)

Smart ballast systems enhance Ballast Water Management System (BWMS) efficiency by integrating real-time data analytics, automated monitoring, and energy-saving technologies, surpassing traditional ballast automation in compliance, operational accuracy, and ecological impact reduction.

Real-time Sensor Integration

Smart ballast systems leverage real-time sensor integration to dynamically adjust water levels and optimize stability, significantly enhancing efficiency and responsiveness compared to traditional ballast automation.

Adaptive Ballasting Algorithms

Adaptive ballasting algorithms in smart ballast systems optimize load distribution in real-time, enhancing energy efficiency and reducing wear compared to traditional ballast automation methods.

Remote Monitoring and Diagnostics

Smart ballast systems enable real-time remote monitoring and diagnostics that enhance maintenance efficiency and reduce downtime compared to traditional ballast automation lacking advanced connectivity features.

Cyber-physical Ballast Control

Cyber-physical ballast control in smart ballast systems enhances precision and real-time monitoring compared to traditional ballast automation, leading to improved vessel stability and energy efficiency.

Predictive Maintenance Scheduling

Smart ballast systems enable predictive maintenance scheduling through real-time sensor data and advanced analytics, reducing downtime and extending equipment lifespan compared to traditional ballast automation.

Digital Twin Simulation

Smart ballast systems utilize Digital Twin Simulation to optimize performance and predictive maintenance, outperforming traditional ballast automation by enabling real-time monitoring and accurate virtual modeling of physical ballast conditions.

Energy-efficient Ballast Operations

Smart ballast systems reduce energy consumption by up to 30% compared to traditional ballast automation through real-time monitoring and adaptive control algorithms.

Automated Ballast Flow Control Valves

Smart ballast systems equipped with automated ballast flow control valves enhance precision, reduce manual intervention, and improve fuel efficiency compared to traditional ballast automation methods.

Compliance Data Logging Systems

Smart ballast systems enhance compliance data logging by providing real-time monitoring, automated reporting, and precise analytics, surpassing traditional ballast automation's manual and intermittent compliance tracking.

Smart ballast systems vs traditional ballast automation Infographic

njnir.com

njnir.com