Azimuth thrusters provide superior maneuverability and precise steering by allowing 360-degree rotation, unlike conventional propellers fixed in position. They enhance vessel efficiency in tight spaces such as harbors or during dynamic positioning operations, reducing the need for additional rudders. Conventional propellers, while generally more cost-effective and simpler in design, offer less agility and are better suited for straight-line cruising at constant speeds.

Table of Comparison

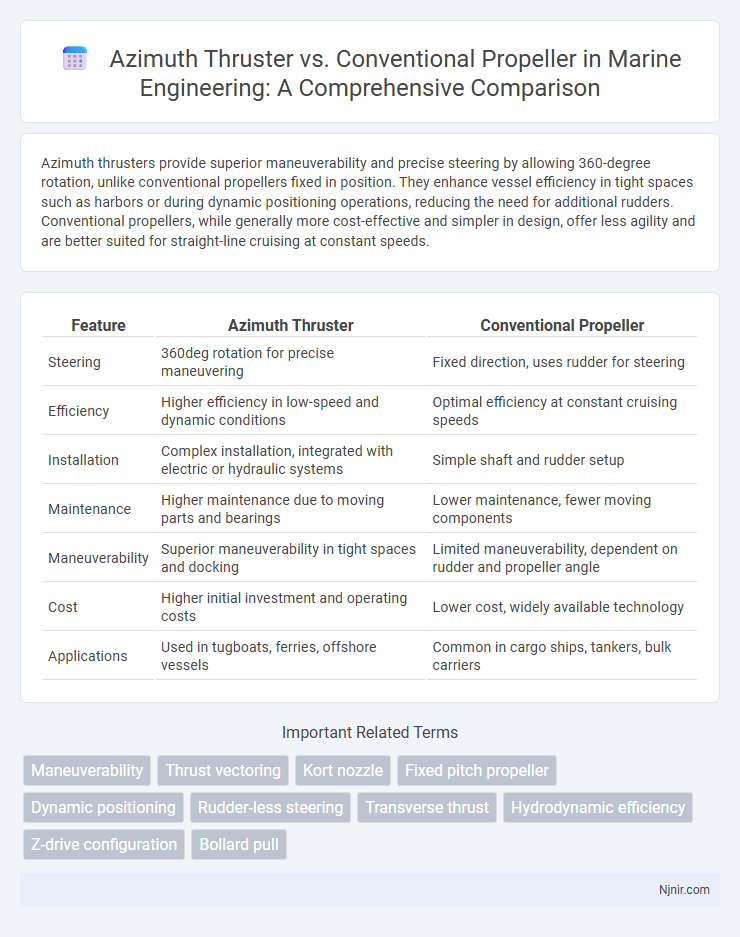

| Feature | Azimuth Thruster | Conventional Propeller |

|---|---|---|

| Steering | 360deg rotation for precise maneuvering | Fixed direction, uses rudder for steering |

| Efficiency | Higher efficiency in low-speed and dynamic conditions | Optimal efficiency at constant cruising speeds |

| Installation | Complex installation, integrated with electric or hydraulic systems | Simple shaft and rudder setup |

| Maintenance | Higher maintenance due to moving parts and bearings | Lower maintenance, fewer moving components |

| Maneuverability | Superior maneuverability in tight spaces and docking | Limited maneuverability, dependent on rudder and propeller angle |

| Cost | Higher initial investment and operating costs | Lower cost, widely available technology |

| Applications | Used in tugboats, ferries, offshore vessels | Common in cargo ships, tankers, bulk carriers |

Introduction to Marine Propulsion Systems

Azimuth thrusters provide 360-degree rotation, enabling superior maneuverability compared to conventional fixed propellers, which require rudders for steering. Marine propulsion systems incorporating azimuth thrusters enhance vessel control in tight spaces, making them ideal for tugs, offshore supply vessels, and dynamic positioning ships. Conventional propellers remain prevalent in bulk carriers and tankers due to their simpler design, durability, and fuel efficiency in straightforward navigation scenarios.

Overview of Azimuth Thrusters

Azimuth thrusters provide 360-degree rotation for enhanced maneuverability compared to conventional fixed propellers, which typically offer limited directional control. These thrusters integrate propulsion and steering in one unit, enabling precise vessel positioning and improved handling in tight spaces or adverse conditions. The advanced design reduces the need for rudders and stern thrusters, increasing overall efficiency and operational flexibility.

Overview of Conventional Propellers

Conventional propellers consist of a fixed shaft with blades rotating around it, providing thrust by pushing water backward to propel the vessel forward. These propellers are typically mounted at the stern and rely on rudders for directional control, resulting in less maneuverability compared to azimuth thrusters. Their efficiency and simplicity make them widely used in various commercial and recreational ships, especially where high-speed cruising is required.

Maneuverability Comparison

Azimuth thrusters provide superior maneuverability compared to conventional propellers due to their ability to rotate 360 degrees, allowing for precise directional control and rapid changes in thrust direction. Conventional propellers, typically fixed in position with rudders for steering, offer less responsiveness and require larger turning radii. The enhanced agility of azimuth thrusters is particularly advantageous for vessels operating in confined waters or requiring dynamic positioning.

Efficiency and Performance Analysis

Azimuth thrusters offer superior maneuverability and fuel efficiency compared to conventional propellers, enabling precise vessel control and reduced hydrodynamic losses. Their ability to rotate 360 degrees improves thrust vectoring, leading to enhanced performance in tight navigation and dynamic positioning systems. Conventional propellers, while simpler and more robust, generally exhibit lower propulsion efficiency due to fixed direction thrust and limited control in varying marine conditions.

Installation and Maintenance Considerations

Azimuth thrusters offer flexible installation options due to their ability to rotate 360 degrees, eliminating the need for complex rudder systems and reducing hull penetrations compared to conventional propellers. Maintenance of azimuth thrusters can be more straightforward since they are typically mounted externally and allow easier access for inspection and repairs, whereas conventional propellers often require dry-docking for propeller shaft servicing. However, azimuth thrusters entail specialized components such as electric or hydraulic drive systems that may demand specific technical expertise and regular preventive maintenance.

Space and Design Flexibility

Azimuth thrusters enhance spatial efficiency by integrating a 360-degree rotating propulsion system, eliminating the need for separate rudders and allowing for streamlined hull designs. Their compact footprint provides superior design flexibility, enabling innovative vessel layouts and optimized internal space utilization compared to conventional fixed propeller systems. This adaptability improves maneuverability and operational performance in diverse maritime applications.

Operational Applications in Marine Vessels

Azimuth thrusters provide superior maneuverability and precise directional control, making them ideal for dynamic positioning in offshore vessels, tugboats, and ferries. Conventional propellers are more efficient for steady, straight-line cruising, commonly used in cargo ships and large tankers where fuel economy is critical. The choice between azimuth thrusters and conventional propellers depends heavily on vessel operational needs, including maneuverability requirements and voyage profiles.

Cost Implications and Lifecycle Assessment

Azimuth thrusters often have higher upfront costs compared to conventional propellers due to their advanced steering mechanisms and increased complexity, impacting initial capital investment. Lifecycle assessment reveals azimuth thrusters can offer improved fuel efficiency and maneuverability, potentially lowering operational expenses over time despite higher maintenance costs from more intricate components. Conventional propellers typically incur lower maintenance and repair costs but may lead to increased fuel consumption and reduced vessel agility, influencing total lifecycle cost-effectiveness.

Future Trends in Marine Propulsion Technology

Azimuth thrusters offer enhanced maneuverability and fuel efficiency compared to conventional propellers, driving their adoption in advanced marine propulsion systems. Future trends emphasize integration with hybrid and electric power sources, improving energy efficiency and reducing emissions. Innovations in autonomous vessel technology further leverage azimuth thrusters for precise navigation and operational flexibility in complex maritime environments.

Maneuverability

Azimuth thrusters provide superior maneuverability compared to conventional propellers by enabling 360-degree rotation and precise directional control.

Thrust vectoring

Azimuth thrusters provide superior thrust vectoring by enabling 360-degree rotation for enhanced maneuverability compared to fixed-direction conventional propellers.

Kort nozzle

Azimuth thrusters equipped with Kort nozzles provide superior thrust efficiency and maneuverability compared to conventional propellers by directing water flow through the nozzle, increasing thrust at low speeds and enhancing vessel control.

Fixed pitch propeller

Azimuth thrusters provide enhanced maneuverability and 360-degree rotation compared to conventional fixed pitch propellers, which offer simpler design and greater efficiency at constant speeds.

Dynamic positioning

Azimuth thrusters provide superior dynamic positioning accuracy and maneuverability compared to conventional propellers by enabling 360-degree rotation and precise thrust vectoring in real-time.

Rudder-less steering

Azimuth thrusters provide precise rudder-less steering by rotating 360 degrees, enhancing maneuverability and control compared to conventional propellers which rely on separate rudders for directional changes.

Transverse thrust

Azimuth thrusters provide superior transverse thrust and enhanced maneuverability compared to conventional propellers due to their 360-degree rotational capability.

Hydrodynamic efficiency

Azimuth thrusters offer superior hydrodynamic efficiency compared to conventional propellers by enabling 360-degree rotation, reducing drag, and optimizing thrust direction for improved maneuverability and fuel savings.

Z-drive configuration

The Z-drive azimuth thruster offers superior maneuverability and 360-degree rotation compared to conventional fixed propellers, enabling enhanced vessel control and efficiency.

Bollard pull

Azimuth thrusters provide higher bollard pull and enhanced maneuverability compared to conventional propellers by delivering 360-degree directional thrust.

azimuth thruster vs conventional propeller Infographic

njnir.com

njnir.com