Waterjet propulsion offers superior maneuverability and reduced cavitation compared to traditional propellers, making it ideal for high-speed marine vessels. It provides enhanced shallow water operation and decreased environmental impact due to minimized underwater noise and vibration. Traditional propellers excel in fuel efficiency for steady cruising speeds but often suffer from damage and performance loss in debris-laden waters.

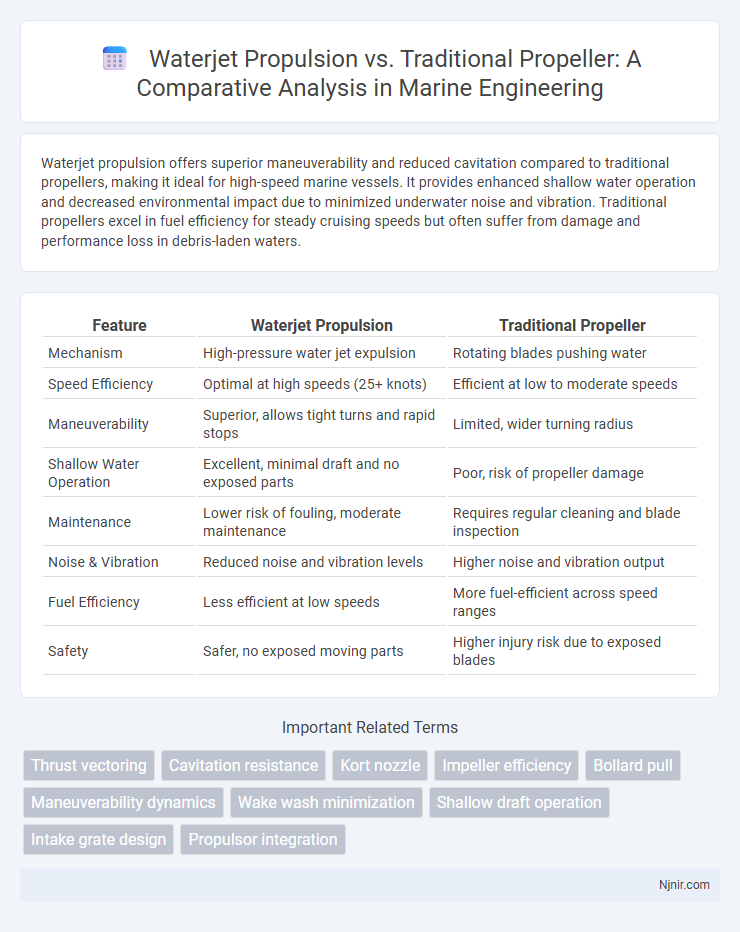

Table of Comparison

| Feature | Waterjet Propulsion | Traditional Propeller |

|---|---|---|

| Mechanism | High-pressure water jet expulsion | Rotating blades pushing water |

| Speed Efficiency | Optimal at high speeds (25+ knots) | Efficient at low to moderate speeds |

| Maneuverability | Superior, allows tight turns and rapid stops | Limited, wider turning radius |

| Shallow Water Operation | Excellent, minimal draft and no exposed parts | Poor, risk of propeller damage |

| Maintenance | Lower risk of fouling, moderate maintenance | Requires regular cleaning and blade inspection |

| Noise & Vibration | Reduced noise and vibration levels | Higher noise and vibration output |

| Fuel Efficiency | Less efficient at low speeds | More fuel-efficient across speed ranges |

| Safety | Safer, no exposed moving parts | Higher injury risk due to exposed blades |

Introduction to Marine Propulsion Systems

Waterjet propulsion offers high maneuverability and shallow water operation advantages compared to traditional propellers commonly used in marine propulsion systems. Waterjets generate thrust by accelerating water through an internal pump and ejecting it at high velocity, resulting in less drag and reduced risk of damage from underwater objects. Traditional propeller systems, while efficient at lower speeds, often face limitations in agility and vulnerability in harsh marine environments.

Overview of Waterjet Propulsion Technology

Waterjet propulsion technology uses high-speed jets of water ejected from a nozzle to generate thrust, providing enhanced maneuverability and shallow-water operation compared to traditional propellers. This system minimizes the risk of damage from debris or grounding while offering superior acceleration and safety for vessels in confined or hazardous waters. Waterjets are commonly employed in high-speed boats and naval vessels due to their compact design and efficient thrust-to-weight ratio.

Fundamentals of Traditional Propeller Systems

Traditional propeller systems operate by converting rotational energy from the engine into thrust through the blades, which create a pressure difference in the water to propel the vessel forward. Blade design, pitch, diameter, and rotational speed are crucial factors influencing the efficiency and performance of traditional propellers. Despite their widespread use, traditional propeller systems are susceptible to cavitation and mechanical damage, which can reduce propulsion efficiency and increase maintenance requirements.

Efficiency Comparison: Waterjets vs Propellers

Waterjet propulsion offers higher efficiency at high speeds due to reduced drag and enhanced maneuverability, making it ideal for fast vessels and shallow waters. Traditional propellers excel in fuel efficiency at lower speeds and provide greater thrust for heavy loads, benefiting larger ships and cargo vessels. Efficiency comparison highlights waterjets' superior performance in speed and agility, while propellers maintain advantages in low-speed fuel economy and heavy-duty applications.

Maneuverability and Handling Differences

Waterjet propulsion offers superior maneuverability compared to traditional propellers by allowing rapid changes in thrust direction and providing precise control at low speeds. The absence of exposed rotating blades reduces the risk of damage and enables higher operational safety in shallow or debris-filled waters. In contrast, traditional propellers often struggle with responsiveness and require a rudder for directional changes, limiting their effectiveness in tight or complex navigation scenarios.

Performance in Shallow vs Deep Waters

Waterjet propulsion offers superior maneuverability and reduced risk of damage in shallow waters due to its enclosed jet system, making it ideal for environments with debris or underwater obstacles. Traditional propellers provide higher efficiency and thrust in deep waters, delivering better fuel economy and speed performance on open seas. This contrast underscores waterjets' advantage in shallow, constraint-rich zones, while propellers dominate deep-water scenarios with optimized hydrodynamic efficiency.

Maintenance and Durability Considerations

Waterjet propulsion systems generally require less maintenance than traditional propellers because they have fewer moving external parts vulnerable to damage, such as blades and shafts, which reduces corrosion and fouling risks. The enclosed impeller in waterjet systems enhances durability by protecting components from debris and impact, leading to lower repair costs and longer service intervals. However, traditional propellers, while more exposed, have simpler designs that allow for easier and quicker repairs in many maritime applications.

Environmental Impact and Noise Levels

Waterjet propulsion produces significantly lower underwater noise levels compared to traditional propellers, reducing marine life disturbance and enhancing aquatic ecosystem health. Its design minimizes cavitation, which is a primary source of noise pollution in conventional propeller systems. Additionally, waterjet systems generate less vibration and can decrease the emission of underwater pollutants, contributing to improved environmental sustainability in marine transportation.

Application Suitability: Choosing the Right System

Waterjet propulsion offers superior maneuverability and shallow water capability, making it ideal for high-speed vessels, rescue boats, and recreational crafts operating in coastal or inland waters. Traditional propellers deliver higher fuel efficiency and better thrust at lower speeds, which suits large cargo ships, fishing vessels, and slow-moving commercial boats in deep waters. Selecting the right system depends on operational environment, speed requirements, and vessel size to optimize performance and safety.

Future Trends in Marine Propulsion Technologies

Waterjet propulsion is gaining traction in marine propulsion technologies due to its superior maneuverability, higher efficiency at high speeds, and reduced environmental impact compared to traditional propellers. Future trends emphasize integrating advanced materials and electric hybrid systems to enhance waterjet performance while minimizing noise and vibration. Innovations in computational fluid dynamics (CFD) and control algorithms are driving optimization of waterjet designs, promoting their adoption in commercial, military, and recreational vessels over conventional propellers.

Thrust vectoring

Waterjet propulsion provides superior thrust vectoring capabilities compared to traditional propellers, enabling enhanced maneuverability and precise directional control in marine vessels.

Cavitation resistance

Waterjet propulsion offers superior cavitation resistance compared to traditional propellers by utilizing high-pressure water jets that reduce localized pressure drops and minimize bubble formation.

Kort nozzle

Waterjet propulsion with a Kort nozzle enhances thrust and maneuverability by channeling water flow through a duct, increasing efficiency compared to traditional open propellers, especially in low-speed and high-load marine applications.

Impeller efficiency

Waterjet propulsion achieves higher impeller efficiency by reducing cavitation and optimizing flow dynamics compared to traditional propeller systems.

Bollard pull

Waterjet propulsion typically delivers lower bollard pull compared to traditional propellers, making propellers more effective for high-thrust applications like tugboats and heavy towing.

Maneuverability dynamics

Waterjet propulsion offers superior maneuverability dynamics compared to traditional propellers by enabling rapid acceleration, precise directional control, and enhanced performance in shallow waters.

Wake wash minimization

Waterjet propulsion significantly reduces wake wash compared to traditional propellers by ejecting water in a high-velocity jet, minimizing turbulence and environmental impact in sensitive marine areas.

Shallow draft operation

Waterjet propulsion provides superior shallow draft operation by minimizing underwater appendages and reducing the risk of damage compared to traditional propellers.

Intake grate design

Waterjet propulsion systems utilize intake grates designed to optimize water flow and prevent debris ingestion, significantly reducing clogging compared to traditional propeller intake designs.

Propulsor integration

Waterjet propulsion integrates compactly into hull designs, improving maneuverability and reducing draft, while traditional propellers require larger shaft spaces and rudder assemblies for effective operation.

Waterjet propulsion vs Traditional propeller Infographic

njnir.com

njnir.com