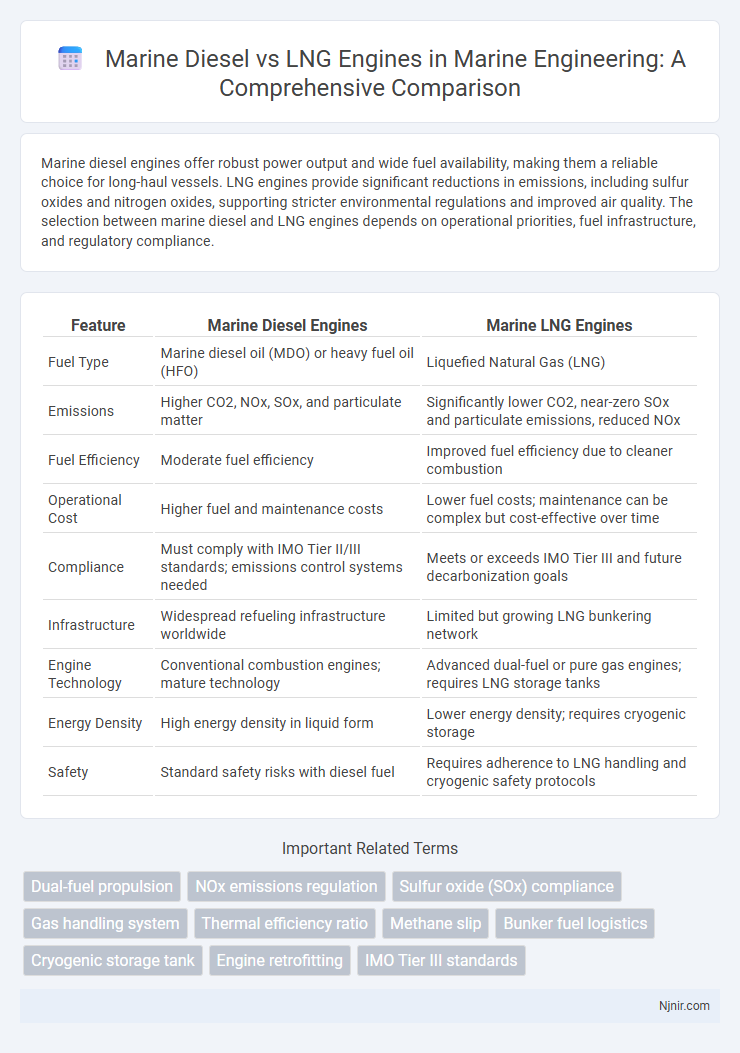

Marine diesel engines offer robust power output and wide fuel availability, making them a reliable choice for long-haul vessels. LNG engines provide significant reductions in emissions, including sulfur oxides and nitrogen oxides, supporting stricter environmental regulations and improved air quality. The selection between marine diesel and LNG engines depends on operational priorities, fuel infrastructure, and regulatory compliance.

Table of Comparison

| Feature | Marine Diesel Engines | Marine LNG Engines |

|---|---|---|

| Fuel Type | Marine diesel oil (MDO) or heavy fuel oil (HFO) | Liquefied Natural Gas (LNG) |

| Emissions | Higher CO2, NOx, SOx, and particulate matter | Significantly lower CO2, near-zero SOx and particulate emissions, reduced NOx |

| Fuel Efficiency | Moderate fuel efficiency | Improved fuel efficiency due to cleaner combustion |

| Operational Cost | Higher fuel and maintenance costs | Lower fuel costs; maintenance can be complex but cost-effective over time |

| Compliance | Must comply with IMO Tier II/III standards; emissions control systems needed | Meets or exceeds IMO Tier III and future decarbonization goals |

| Infrastructure | Widespread refueling infrastructure worldwide | Limited but growing LNG bunkering network |

| Engine Technology | Conventional combustion engines; mature technology | Advanced dual-fuel or pure gas engines; requires LNG storage tanks |

| Energy Density | High energy density in liquid form | Lower energy density; requires cryogenic storage |

| Safety | Standard safety risks with diesel fuel | Requires adherence to LNG handling and cryogenic safety protocols |

Introduction to Marine Diesel and LNG Engines

Marine diesel engines have long been the backbone of maritime propulsion due to their high efficiency, reliability, and widespread fueling infrastructure, operating primarily on heavy fuel oil or marine diesel oil. LNG engines offer a cleaner alternative, utilizing liquefied natural gas to significantly reduce greenhouse gas emissions and meet stricter International Maritime Organization (IMO) environmental regulations. The transition from marine diesel to LNG engines represents a critical shift in the shipping industry towards sustainability and compliance with evolving environmental standards.

Fuel Characteristics and Availability

Marine diesel engines rely on heavy fuel oil or marine diesel oil, which has high energy density but contains sulfur and produces more emissions. LNG engines use liquefied natural gas, offering cleaner combustion with lower sulfur content and reduced greenhouse gas emissions, enhancing compliance with IMO sulfur regulations. Availability of marine diesel is widespread globally, while LNG infrastructure is rapidly expanding, especially in major ports, but remains limited in some regions, influencing fuel choice for shipping operators.

Emissions and Environmental Impact

Marine diesel engines emit higher levels of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter, contributing significantly to air pollution and acid rain. LNG engines produce substantially lower emissions of SOx and particulate matter, and emit up to 20-30% less CO2, reducing greenhouse gas impact and improving compliance with IMO sulfur caps. The shift to LNG as marine fuel supports cleaner shipping operations, aligning with global environmental regulations and reducing the vessel's overall carbon footprint.

Engine Efficiency and Performance

Marine diesel engines typically offer higher energy density and reliable performance with well-established fuel infrastructure, achieving thermal efficiencies around 45-50%. LNG engines provide cleaner combustion, significantly reducing NOx, SOx, and particulate emissions while maintaining comparable power output and efficiency levels near 45%. Advances in LNG engine technology enhance fuel flexibility and optimize engine tuning, resulting in improved performance and reduced greenhouse gas emissions compared to conventional marine diesel engines.

Operational Costs and Economic Comparison

Marine diesel engines generally incur higher operational costs due to increased fuel consumption and maintenance requirements compared to LNG engines. LNG engines offer significant economic advantages with lower fuel prices, reduced sulfur oxide emissions, and compliance with stricter environmental regulations, resulting in cost savings over time. The initial investment for LNG engine technology is higher, but the long-term operational cost efficiency and regulatory benefits provide a compelling financial advantage.

Maintenance Requirements and Service Life

Marine diesel engines typically require more frequent maintenance due to their complex fuel injection systems and higher operating temperatures, resulting in shorter intervals between overhauls compared to LNG engines. LNG engines benefit from cleaner combustion, reducing carbon deposits and wear on components, which extends service life and lowers overall maintenance costs. The average service life of marine diesel engines ranges from 15 to 25 years, while LNG engines can often exceed 25 years with proper maintenance, enhancing vessel operational efficiency and longevity.

Safety Considerations and Regulations

Marine diesel engines are subject to rigorous safety standards such as the International Maritime Organization's (IMO) MARPOL Annex VI regulations, which address emission controls and fuel quality to prevent environmental hazards. LNG engines, while offering reduced emissions, require specialized safety protocols including gas detection systems and rigorous ventilation requirements due to the flammability and low temperature of liquefied natural gas. Compliance with Classification Societies' standards, such as those from the American Bureau of Shipping (ABS) and DNV GL, ensures both engine types meet strict operational safety and maintenance regulations to mitigate risks during maritime operations.

Infrastructure and Bunkering Challenges

Marine diesel engines benefit from extensive existing infrastructure, including widespread bunkering facilities and well-established supply chains, enabling efficient refueling worldwide. In contrast, LNG engines face significant bunkering challenges due to limited LNG bunker availability, high initial investment costs for specialized infrastructure, and the need for strict safety protocols during handling. The transition to LNG requires coordinated development of LNG bunkering terminals and vessels, which currently limits its adoption despite environmental advantages.

Future Trends in Marine Propulsion

The future of marine propulsion increasingly favors LNG engines due to their lower sulfur emissions and compliance with IMO 2020 regulations, positioning them as a cleaner alternative to traditional marine diesel engines. Advances in LNG bunkering infrastructure and hybrid propulsion systems are accelerating the adoption of LNG, optimizing fuel efficiency and reducing greenhouse gas emissions in the shipping industry. Emerging technologies like dual-fuel engines and battery integration further enhance operational flexibility and sustainability, shaping the evolution of next-generation marine propulsion.

Decision Factors for Engine Selection

Marine diesel engines offer higher energy density and established refueling infrastructure, making them favorable for long-haul shipping routes with limited port LNG availability. LNG engines provide substantial reductions in sulfur oxides (SOx), nitrogen oxides (NOx), and carbon dioxide (CO2) emissions, aligning with increasingly stringent IMO environmental regulations for emission control areas (ECAs). Vessel operational profile, fuel cost volatility, emissions compliance, and availability of LNG bunkering facilities are critical decision factors influencing the selection between marine diesel and LNG propulsion systems.

Dual-fuel propulsion

Dual-fuel propulsion systems in marine engines optimize fuel efficiency and reduce emissions by seamlessly switching between marine diesel and liquefied natural gas (LNG), leveraging LNG's lower carbon footprint and diesel's high energy density for enhanced environmental compliance and operational flexibility.

NOx emissions regulation

Marine diesel engines produce higher NOx emissions compared to LNG engines, which comply more effectively with IMO Tier III regulations for nitrogen oxide reduction in shipping.

Sulfur oxide (SOx) compliance

Marine diesel engines emit higher sulfur oxide (SOx) levels, necessitating costly exhaust gas cleaning systems or low-sulfur fuel, while LNG engines inherently comply with stringent SOx regulations due to near-zero sulfur content.

Gas handling system

Marine LNG engines require complex gas handling systems including cryogenic storage, vaporization units, and safety valves, while marine diesel engines utilize simpler fuel delivery systems with liquid fuel pumps and injectors.

Thermal efficiency ratio

Marine diesel engines typically achieve a thermal efficiency ratio of 40-50%, whereas LNG engines can reach up to 50-55%, offering improved fuel efficiency and lower emissions.

Methane slip

Methane slip in marine diesel engines is significantly higher than in LNG engines, making LNG engines a cleaner alternative for reducing greenhouse gas emissions in maritime transport.

Bunker fuel logistics

Marine LNG engines reduce bunker fuel logistics complexity by enabling cleaner, more efficient fuel storage and refueling compared to traditional marine diesel systems.

Cryogenic storage tank

Marine LNG engines require advanced cryogenic storage tanks capable of maintaining LNG at approximately -162degC to ensure fuel stability and safety, unlike marine diesel engines which use conventional fuel tanks operating at ambient temperatures.

Engine retrofitting

Engine retrofitting from marine diesel to LNG propulsion reduces emissions by up to 25%, improves fuel efficiency by 15%, and complies with IMO 2020 sulfur cap regulations.

IMO Tier III standards

Marine diesel engines emit higher NOx levels compared to LNG engines, making LNG propulsion more compliant with IMO Tier III standards for reducing nitrogen oxide emissions in designated emission control areas.

marine diesel vs LNG engines Infographic

njnir.com

njnir.com