Azimuth thrusters provide superior maneuverability and efficiency compared to conventional propellers by allowing 360-degree rotation for precise directional control without the need for rudders. Their compact design reduces hull resistance, enhancing fuel efficiency and performance in tight or shallow waters. Conventional propellers, while simpler and often more robust for straightforward propulsion, lack the flexibility in steering and dynamic positioning that azimuth thrusters offer.

Table of Comparison

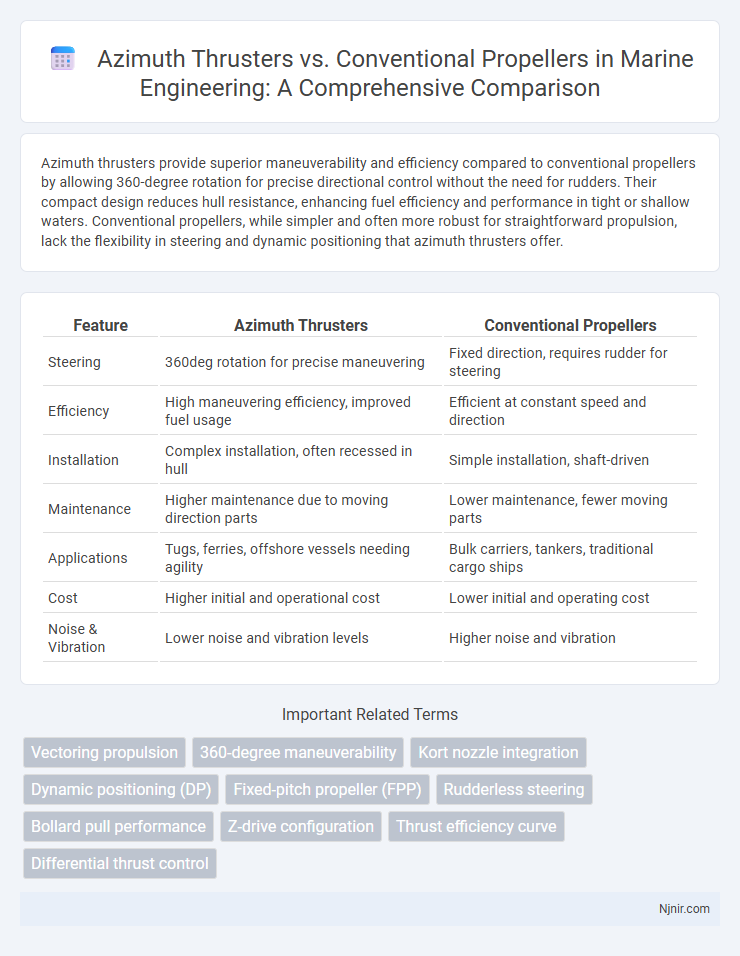

| Feature | Azimuth Thrusters | Conventional Propellers |

|---|---|---|

| Steering | 360deg rotation for precise maneuvering | Fixed direction, requires rudder for steering |

| Efficiency | High maneuvering efficiency, improved fuel usage | Efficient at constant speed and direction |

| Installation | Complex installation, often recessed in hull | Simple installation, shaft-driven |

| Maintenance | Higher maintenance due to moving direction parts | Lower maintenance, fewer moving parts |

| Applications | Tugs, ferries, offshore vessels needing agility | Bulk carriers, tankers, traditional cargo ships |

| Cost | Higher initial and operational cost | Lower initial and operating cost |

| Noise & Vibration | Lower noise and vibration levels | Higher noise and vibration |

Introduction to Azimuth Thrusters and Conventional Propellers

Azimuth thrusters offer 360-degree rotation, providing superior maneuverability compared to conventional propellers that are fixed in position with limited steering capabilities. Conventional propellers rely on rudders for directional control, whereas azimuth thrusters integrate thrust vectoring and steering into a single unit, enhancing vessel response and positioning. This design difference results in improved efficiency and operational flexibility, especially for dynamic positioning and complex navigational tasks.

Principles of Operation: How Each System Works

Azimuth thrusters operate by rotating 360 degrees around a vertical axis, combining propulsion and steering in a single unit, which allows for enhanced maneuverability and precise directional control. Conventional propellers are fixed in orientation and rely on rudders for steering, where the rotational force generated by the propeller pushes water backwards to move the vessel forward. Azimuth thrusters use electric or hydraulic motors to directly turn the propeller and adjust thrust vector, while conventional propellers transmit torque from an engine through a shaft and gearbox to produce propulsion in a single axial direction.

Maneuverability and Vessel Control

Azimuth thrusters provide superior maneuverability and vessel control compared to conventional propellers by allowing 360-degree rotation for precise directional thrust, facilitating tight turning circles and rapid course adjustments. This enhanced control is particularly advantageous for vessels operating in confined waters or requiring dynamic positioning, as azimuth thrusters enable lateral movement and station-keeping without auxiliary devices. Conventional propellers, relying on rudders for steering, offer less flexibility, leading to slower response times and reduced handling efficiency in complex navigational scenarios.

Efficiency and Fuel Consumption Comparison

Azimuth thrusters provide superior maneuverability and can improve propulsion efficiency by optimizing thrust direction, often resulting in lower fuel consumption compared to conventional fixed propellers. Studies indicate azimuth thrusters reduce fuel usage by up to 15% in dynamic operating conditions due to enhanced hydrodynamic performance and reduced need for auxiliary thrusters. Conventional propellers typically exhibit less efficiency in complex navigation scenarios, leading to higher overall fuel consumption and increased emissions.

Installation and Maintenance Requirements

Azimuth thrusters offer greater installation flexibility by eliminating the need for rudders and allowing 360-degree rotation, which simplifies steering systems compared to conventional propellers fixed to shafts with separate rudders. Maintenance requirements for azimuth thrusters typically involve more specialized servicing due to integrated complex gearboxes and electric or hydraulic motors, whereas conventional propellers require routine shaft and rudder inspections but generally have simpler mechanical components. The space-saving design of azimuth thrusters also reduces hull modifications during installation, optimizing vessel layout and reducing downtime.

Applications and Vessel Types

Azimuth thrusters offer superior maneuverability and are widely used in offshore supply vessels, tugboats, and dynamic positioning ships, where precise control and multidirectional thrust are critical. Conventional propellers remain the preferred choice for large cargo ships, tankers, and container vessels due to their simplicity, fuel efficiency, and cost-effectiveness in steady, long-distance navigation. The choice between azimuth thrusters and conventional propellers largely depends on vessel type, operational requirements, and navigational complexity.

Cost Analysis: Initial and Operational Expenses

Azimuth thrusters typically have higher initial costs compared to conventional propellers due to their complex design and advanced maneuverability features. Operational expenses for azimuth thrusters can be lower in certain applications because of improved fuel efficiency and reduced need for tug assistance, which cuts down on labor and fuel costs. Maintenance costs vary, with azimuth thrusters requiring specialized servicing that may increase expenses, while conventional propellers have simpler designs that generally lead to lower routine maintenance fees.

Environmental Impact and Emissions

Azimuth thrusters offer improved fuel efficiency and reduced emissions compared to conventional propellers due to their enhanced maneuverability and optimized hydrodynamic performance, leading to lower greenhouse gas outputs. Their ability to provide precise directional control minimizes unnecessary fuel consumption during vessel operations, helping to decrease the carbon footprint of maritime activities. Conventional propellers, while simpler in design, often require more power and generate higher emissions due to less efficient propulsion, making azimuth thrusters a more environmentally sustainable choice for modern shipping and offshore vessels.

Reliability and Performance in Rough Conditions

Azimuth thrusters offer superior maneuverability and maintain propulsion efficiency in rough sea conditions due to their 360-degree rotation capability, enhancing vessel control compared to conventional fixed propellers. Their design minimizes cavitation and vibration, resulting in improved reliability and reduced mechanical wear during turbulent operations. Conventional propellers, while generally robust, can experience performance degradation and increased maintenance needs when exposed to harsh marine environments with unpredictable wave patterns.

Future Trends and Technological Developments

Azimuth thrusters are advancing rapidly with developments in electric propulsion, integration of automation systems, and improvements in maneuverability for autonomous vessels, setting new standards in energy efficiency and environmental compliance. Conventional propellers continue to evolve through hybrid powertrain integration and enhanced blade designs that optimize fuel consumption and reduce noise pollution. Future trends point towards increased adoption of azimuth thrusters in offshore and commercial shipping sectors, driven by demand for greater operational flexibility and reduced carbon emissions.

Vectoring propulsion

Azimuth thrusters provide superior vectoring propulsion by enabling 360-degree rotation for enhanced maneuverability compared to the fixed-direction thrust of conventional propellers.

360-degree maneuverability

Azimuth thrusters provide 360-degree maneuverability by rotating the entire propulsion unit, offering superior directional control compared to conventional propellers fixed in a single direction.

Kort nozzle integration

Azimuth thrusters integrated with Kort nozzles deliver enhanced thrust and maneuverability compared to conventional propellers by optimizing water flow and increasing propulsive efficiency in low-speed and high-torque marine applications.

Dynamic positioning (DP)

Azimuth thrusters provide superior dynamic positioning (DP) accuracy and maneuverability compared to conventional propellers by enabling 360-degree thrust vectoring and rapid response to environmental changes.

Fixed-pitch propeller (FPP)

Azimuth thrusters provide enhanced maneuverability and directional control compared to fixed-pitch propellers (FPP), which offer simplicity and reliability but limited steering capabilities.

Rudderless steering

Azimuth thrusters provide rudderless steering by rotating 360 degrees for enhanced maneuverability, unlike conventional propellers that rely on separate rudders for directional control.

Bollard pull performance

Azimuth thrusters deliver higher bollard pull performance than conventional propellers due to their 360-degree rotational capability and optimized thrust direction.

Z-drive configuration

Azimuth thrusters in Z-drive configuration offer 360-degree rotation for superior maneuverability and precise vessel control compared to fixed-direction conventional propellers.

Thrust efficiency curve

Azimuth thrusters exhibit a more consistent and higher thrust efficiency curve across varying speeds and maneuvering angles compared to conventional propellers, enhancing vessel performance and fuel economy.

Differential thrust control

Azimuth thrusters provide superior differential thrust control compared to conventional propellers by enabling 360-degree rotation for enhanced maneuverability and precise directional thrust adjustments.

Azimuth thrusters vs conventional propellers Infographic

njnir.com

njnir.com