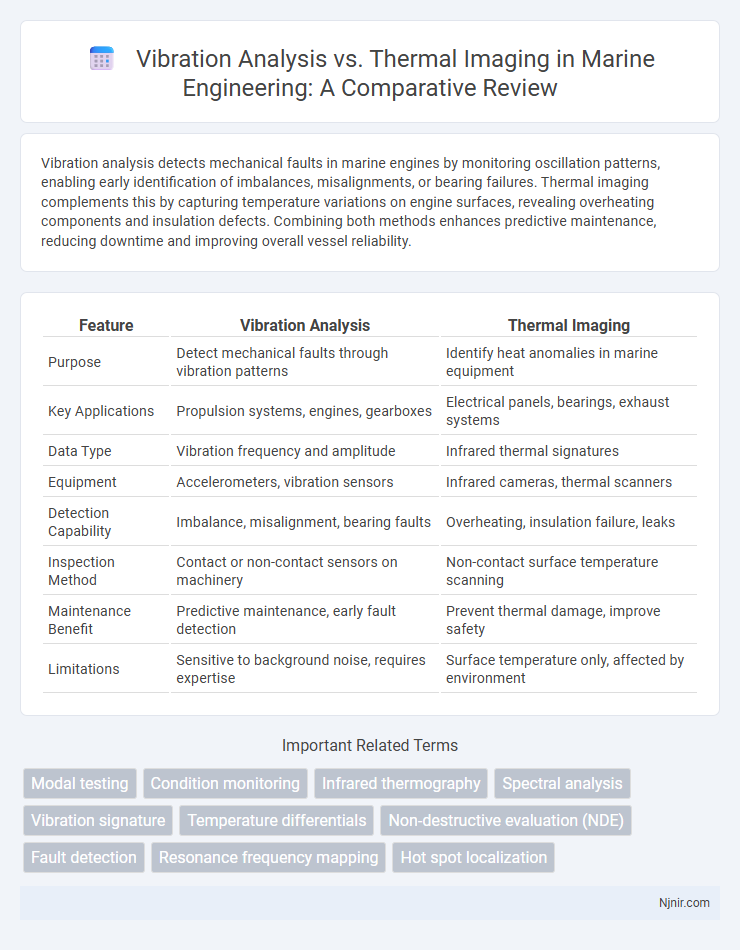

Vibration analysis detects mechanical faults in marine engines by monitoring oscillation patterns, enabling early identification of imbalances, misalignments, or bearing failures. Thermal imaging complements this by capturing temperature variations on engine surfaces, revealing overheating components and insulation defects. Combining both methods enhances predictive maintenance, reducing downtime and improving overall vessel reliability.

Table of Comparison

| Feature | Vibration Analysis | Thermal Imaging |

|---|---|---|

| Purpose | Detect mechanical faults through vibration patterns | Identify heat anomalies in marine equipment |

| Key Applications | Propulsion systems, engines, gearboxes | Electrical panels, bearings, exhaust systems |

| Data Type | Vibration frequency and amplitude | Infrared thermal signatures |

| Equipment | Accelerometers, vibration sensors | Infrared cameras, thermal scanners |

| Detection Capability | Imbalance, misalignment, bearing faults | Overheating, insulation failure, leaks |

| Inspection Method | Contact or non-contact sensors on machinery | Non-contact surface temperature scanning |

| Maintenance Benefit | Predictive maintenance, early fault detection | Prevent thermal damage, improve safety |

| Limitations | Sensitive to background noise, requires expertise | Surface temperature only, affected by environment |

Introduction to Marine Machinery Diagnostics

Vibration analysis detects mechanical faults in marine machinery by monitoring oscillation patterns and identifying abnormalities in rotating components such as shafts, bearings, and gears. Thermal imaging complements this by capturing infrared radiation to reveal temperature variations indicative of insulation failures, misalignments, or overheating parts. Together, these diagnostic techniques enhance predictive maintenance strategies for optimizing marine equipment reliability and minimizing unexpected downtime.

Principles of Vibration Analysis in Marine Engineering

Vibration analysis in marine engineering focuses on detecting mechanical faults by measuring the frequency and amplitude of vibrations in ship machinery, such as engines and propeller shafts. This technique leverages accelerometers and sensors to monitor real-time vibrational patterns, identifying imbalances, misalignments, and bearing failures before they lead to critical breakdowns. Compared to thermal imaging, which detects surface temperature variations to locate overheating components, vibration analysis provides deeper insights into the dynamic behavior and structural integrity of marine propulsion systems.

Fundamentals of Thermal Imaging for Maritime Applications

Thermal imaging detects infrared radiation emitted by objects, enabling the visualization of temperature variations critical for maritime applications such as identifying overheating machinery and electrical faults. This non-contact method enhances safety by allowing early detection of thermal anomalies that could indicate equipment failure or fire hazards on vessels. Unlike vibration analysis, which measures mechanical oscillations, thermal imaging provides spatial temperature distribution, facilitating comprehensive preventive maintenance in maritime environments.

Key Differences Between Vibration Analysis and Thermal Imaging

Vibration analysis detects mechanical faults by measuring oscillations and frequencies in rotating equipment, providing early warnings of imbalance, misalignment, or bearing failures. Thermal imaging identifies temperature variations on equipment surfaces, revealing overheating, insulation defects, or cooling system malfunctions through infrared radiation detection. Vibration analysis targets dynamic mechanical issues, while thermal imaging focuses on thermal anomalies, making each method essential for comprehensive predictive maintenance strategies.

Application Scenarios: When to Use Each Technique

Vibration analysis is ideal for detecting mechanical faults such as imbalance, misalignment, and bearing defects in rotating machinery, making it essential in predictive maintenance for manufacturing plants and power generation equipment. Thermal imaging excels in identifying electrical hotspots, insulation failures, and overheating components, which is critical in electrical systems, building inspections, and HVAC maintenance. Selecting between vibration analysis and thermal imaging depends on whether the focus is on mechanical vibration symptoms or thermal anomalies within equipment and infrastructure.

Accuracy and Reliability in Marine Fault Detection

Vibration analysis in marine fault detection offers high accuracy by capturing mechanical imbalances and misalignments in rotating equipment, providing early-stage fault identification before catastrophic failure. Thermal imaging excels in detecting temperature anomalies related to electrical faults and overheating components, delivering reliable real-time visualization of thermal patterns. Combining both methods enhances fault diagnosis reliability by cross-verifying mechanical and thermal signs of wear or malfunction in marine machinery.

Cost and Resource Implications for Ship Maintenance

Vibration analysis typically requires specialized sensors and skilled technicians, leading to moderate upfront costs but enabling early fault detection, which reduces long-term maintenance expenses on ships. Thermal imaging, while involving higher initial investment in infrared cameras and training, provides rapid, non-contact inspection of electrical and mechanical components, minimizing downtime and labor costs during ship maintenance. Both techniques complement each other by optimizing resource allocation, with vibration analysis focusing on rotating equipment health and thermal imaging targeting heat-related anomalies, ultimately enhancing cost efficiency in maritime asset management.

Data Interpretation: Vibration Signals vs. Thermal Patterns

Vibration analysis interprets data by analyzing frequency, amplitude, and phase of vibration signals to detect mechanical faults such as misalignment, imbalance, or bearing defects. Thermal imaging evaluates temperature distribution and patterns on equipment surfaces to identify overheating, insulation failures, or electrical issues. Each method provides distinct insights: vibration signals reveal dynamic mechanical conditions, while thermal patterns expose thermal anomalies related to operational inefficiencies or malfunctions.

Integration of Vibration Analysis and Thermal Imaging

Integration of vibration analysis and thermal imaging enhances predictive maintenance by providing comprehensive diagnostic insights into equipment health. Combining vibration data with thermal patterns allows early detection of mechanical faults such as misalignment, imbalance, and overheating, improving accuracy in fault identification. This integrated approach optimizes asset management, reduces downtime, and extends machinery lifespan through more effective condition monitoring.

Future Trends in Marine Condition Monitoring Technologies

Future trends in marine condition monitoring technologies emphasize integrating vibration analysis and thermal imaging to enhance predictive maintenance and fault detection accuracy. Advances in sensor fusion and AI-driven data analytics enable real-time monitoring of mechanical vibrations and temperature anomalies, improving early detection of equipment malfunctions in marine engines and propulsion systems. The emergence of wireless IoT devices and cloud-based platforms facilitates remote monitoring, reducing operational downtime and maintenance costs in the maritime industry.

Modal testing

Modal testing identifies structural vibration modes by analyzing frequency response, while thermal imaging detects surface temperature variations, making vibration analysis more precise for modal parameter characterization.

Condition monitoring

Vibration analysis detects mechanical faults by measuring equipment oscillations, while thermal imaging identifies overheating issues through infrared sensors, both essential for comprehensive condition monitoring.

Infrared thermography

Infrared thermography provides non-contact, real-time temperature mapping essential for detecting heat anomalies in vibration analysis to prevent mechanical failures.

Spectral analysis

Spectral analysis in vibration analysis provides detailed frequency-domain insights into machinery faults, enabling precise fault identification, whereas thermal imaging detects surface temperature anomalies without frequency-specific data.

Vibration signature

Vibration analysis provides detailed vibration signature data that detects mechanical faults early, offering more precise insights into equipment condition than thermal imaging.

Temperature differentials

Vibration analysis detects mechanical faults through abnormal motion patterns while thermal imaging identifies temperature differentials to reveal overheating components.

Non-destructive evaluation (NDE)

Vibration analysis detects mechanical faults through signal frequency changes, while thermal imaging identifies temperature anomalies in equipment, both serving as complementary non-destructive evaluation (NDE) techniques for predictive maintenance.

Fault detection

Vibration analysis detects mechanical faults by identifying abnormal oscillations in equipment, while thermal imaging identifies electrical and thermal faults by capturing heat variations and hotspots.

Resonance frequency mapping

Resonance frequency mapping in vibration analysis provides precise detection of mechanical faults by identifying abnormal vibration signatures, whereas thermal imaging offers complementary surface temperature data but lacks direct resonance frequency insights.

Hot spot localization

Vibration analysis detects mechanical faults by monitoring oscillatory signals, while thermal imaging localizes hot spots by capturing infrared radiation, offering precise temperature mapping for early fault detection.

Vibration analysis vs Thermal imaging Infographic

njnir.com

njnir.com