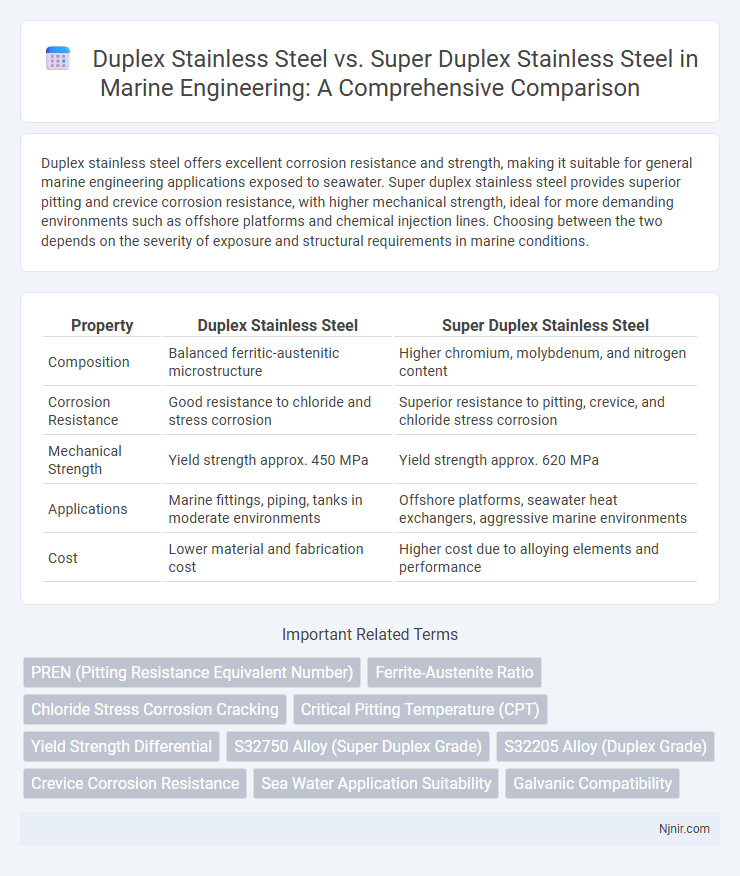

Duplex stainless steel offers excellent corrosion resistance and strength, making it suitable for general marine engineering applications exposed to seawater. Super duplex stainless steel provides superior pitting and crevice corrosion resistance, with higher mechanical strength, ideal for more demanding environments such as offshore platforms and chemical injection lines. Choosing between the two depends on the severity of exposure and structural requirements in marine conditions.

Table of Comparison

| Property | Duplex Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|

| Composition | Balanced ferritic-austenitic microstructure | Higher chromium, molybdenum, and nitrogen content |

| Corrosion Resistance | Good resistance to chloride and stress corrosion | Superior resistance to pitting, crevice, and chloride stress corrosion |

| Mechanical Strength | Yield strength approx. 450 MPa | Yield strength approx. 620 MPa |

| Applications | Marine fittings, piping, tanks in moderate environments | Offshore platforms, seawater heat exchangers, aggressive marine environments |

| Cost | Lower material and fabrication cost | Higher cost due to alloying elements and performance |

Introduction to Duplex and Super Duplex Stainless Steels

Duplex stainless steels consist of approximately equal parts of austenite and ferrite, providing a unique combination of high strength and excellent corrosion resistance, especially in chloride environments. Super duplex stainless steels offer enhanced performance with higher chromium, molybdenum, and nitrogen content, resulting in improved resistance to pitting, crevice corrosion, and stress corrosion cracking. These alloys are widely applied in chemical processing, offshore oil and gas, and marine industries due to their durability and cost-effectiveness compared to austenitic stainless steels.

Chemical Composition Differences

Duplex stainless steel typically contains 18-22% chromium, 4-6% nickel, and 2.5-3.5% molybdenum, while super duplex stainless steel features higher alloying elements with 24-26% chromium, 5-7% nickel, and 3-5% molybdenum. The increased chromium and molybdenum content in super duplex stainless steel enhances corrosion resistance, particularly against pitting and crevice corrosion in aggressive environments. Additionally, super duplex grades often have higher nitrogen levels (0.15-0.35%) compared to duplex stainless steel (0.05-0.15%), which improves mechanical strength and resistance to stress corrosion cracking.

Microstructure Comparison

Duplex stainless steel features a balanced microstructure comprising roughly 50% ferrite and 50% austenite, providing enhanced strength and corrosion resistance compared to standard stainless steels. Super duplex stainless steel contains a similar dual-phase microstructure but with higher alloy content, especially chromium, molybdenum, and nitrogen, which increases ferrite content to about 55-65%, boosting resistance to pitting, crevice corrosion, and stress corrosion cracking. The increased ferrite phase in super duplex stainless steels results in superior mechanical properties and durability in harsh environments such as oil and gas or marine applications.

Mechanical Properties: Strength and Toughness

Duplex stainless steel exhibits a balanced combination of tensile strength typically around 70 ksi (480 MPa) and excellent toughness due to its biphasic microstructure of austenite and ferrite. Super duplex stainless steel offers higher mechanical properties, with tensile strength often exceeding 100 ksi (700 MPa) and enhanced toughness, making it suitable for more demanding environments. The increased nitrogen content and optimized microstructure in super duplex grades significantly improve yield strength and resistance to stress corrosion cracking compared to standard duplex stainless steel.

Corrosion Resistance in Marine Environments

Duplex stainless steel offers excellent corrosion resistance in marine environments due to its balanced microstructure of austenite and ferrite, which enhances pitting and crevice corrosion resistance. Super duplex stainless steel provides superior corrosion resistance with higher alloy content, particularly chromium, molybdenum, and nitrogen, resulting in enhanced resistance to chloride-induced stress corrosion cracking and improved performance in aggressive seawater conditions. Both materials are widely used in marine applications, but super duplex stainless steel is favored for extreme conditions requiring maximum durability and corrosion protection.

Applications in Marine Engineering

Duplex stainless steel, with its balanced austenitic and ferritic phases, offers excellent corrosion resistance and strength, making it suitable for desalination plants and heat exchangers in marine engineering. Super duplex stainless steel provides superior resistance to chloride-induced stress corrosion cracking and higher mechanical strength, ideal for offshore platforms, subsea pipelines, and chemical processing equipment exposed to aggressive saltwater environments. The enhanced performance of super duplex stainless steel ensures longer service life and reduced maintenance in harsh marine conditions.

Welding and Fabrication Challenges

Duplex stainless steel offers excellent weldability with reduced risk of intergranular corrosion but requires precise control of heat input to maintain balanced microstructure and prevent phase segregation. Super duplex stainless steel presents more significant welding challenges due to its higher alloy content, demanding strict control over cooling rates, filler material selection, and post-weld heat treatment to avoid hot cracking and loss of corrosion resistance. Fabrication of super duplex requires specialized procedures and skilled operators to manage its increased hardness and toughness, ensuring structural integrity and desired mechanical properties.

Cost Considerations and Economic Impact

Duplex stainless steel offers a lower upfront cost compared to super duplex stainless steel, making it suitable for applications with moderate corrosion resistance requirements. Super duplex stainless steel, while more expensive initially, delivers superior strength and corrosion resistance, leading to reduced maintenance and longer service life, which can significantly lower total lifecycle costs. Investing in super duplex stainless steel often results in favorable economic impact for industries facing aggressive environments, such as offshore oil and gas, due to decreased downtime and replacement expenses.

Standards and Specifications for Marine Use

Duplex stainless steel grades such as UNS S31803 and S32205 meet ASTM A790 and A995 standards, offering excellent corrosion resistance and strength for marine applications. Super duplex stainless steel, including UNS S32750 and S32760, complies with stricter standards like ASTM A815 and A240, providing superior resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive marine environments. Both materials adhere to ISO 17781 and NORSOK MDS for offshore and subsea use, ensuring optimized performance and durability under harsh conditions.

Choosing the Right Material for Marine Projects

Duplex stainless steel offers excellent corrosion resistance and strength, making it suitable for moderate marine environments, while super duplex stainless steel provides superior resistance to chloride stress corrosion cracking and pitting, ideal for harsher offshore conditions. Selecting the right material depends on the specific exposure to saltwater, temperature, and mechanical stress in the marine project to ensure durability and safety. Super duplex grades, such as UNS S32750, outperform standard duplex (UNS S32205) in highly aggressive environments due to their higher molybdenum and chromium content.

PREN (Pitting Resistance Equivalent Number)

Super duplex stainless steel typically has a higher Pitting Resistance Equivalent Number (PREN) ranging from 38 to 45, compared to duplex stainless steel's PREN of 25 to 35, indicating superior corrosion resistance in chloride-rich environments.

Ferrite-Austenite Ratio

Super duplex stainless steel typically features a balanced ferrite-austenite ratio of approximately 50:50 to enhance corrosion resistance and mechanical strength, whereas duplex stainless steel usually has a ferrite content around 40-60%, affecting its performance in harsh environments.

Chloride Stress Corrosion Cracking

Super duplex stainless steel offers superior resistance to chloride stress corrosion cracking compared to duplex stainless steel due to its higher alloying elements like chromium, molybdenum, and nitrogen.

Critical Pitting Temperature (CPT)

Super duplex stainless steel typically exhibits a higher Critical Pitting Temperature (CPT) than duplex stainless steel, indicating superior resistance to pitting corrosion in aggressive environments.

Yield Strength Differential

Super duplex stainless steel typically exhibits a yield strength differential of approximately 70-90 ksi, significantly higher than duplex stainless steel's 50-65 ksi, enhancing its performance in high-stress applications.

S32750 Alloy (Super Duplex Grade)

S32750 Alloy, a super duplex stainless steel, offers superior corrosion resistance and higher strength compared to standard duplex stainless steel, making it ideal for aggressive environments in chemical processing and offshore applications.

S32205 Alloy (Duplex Grade)

Super Duplex Stainless Steel outperforms Duplex Stainless Steel S32205 alloy by offering higher corrosion resistance and strength, making it ideal for more demanding environments.

Crevice Corrosion Resistance

Super duplex stainless steel offers significantly higher crevice corrosion resistance compared to duplex stainless steel due to its increased chromium, molybdenum, and nitrogen content.

Sea Water Application Suitability

Super duplex stainless steel offers superior corrosion resistance and strength compared to duplex stainless steel, making it more suitable for high-chloride seawater applications.

Galvanic Compatibility

Super duplex stainless steel exhibits superior galvanic compatibility with a wider range of metals compared to duplex stainless steel due to its higher alloy content and enhanced corrosion resistance.

duplex stainless steel vs super duplex stainless steel Infographic

njnir.com

njnir.com