Slow speed engines are primarily used for large ocean-going vessels due to their high thermal efficiency and ability to burn low-quality fuel oil, resulting in lower operational costs. Medium speed engines offer greater flexibility and faster start-up times, making them suitable for smaller ships and auxiliary power generation. Both engine types are integral in marine engineering, with slow speed engines favored for continuous propulsion and medium speed engines preferred for versatility and responsiveness.

Table of Comparison

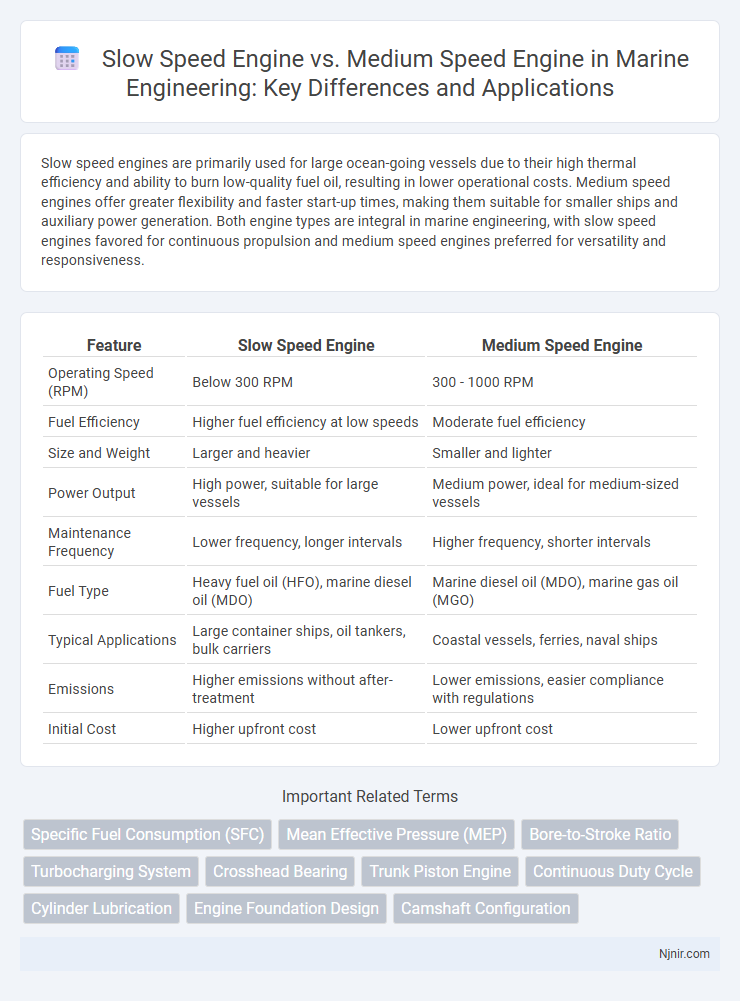

| Feature | Slow Speed Engine | Medium Speed Engine |

|---|---|---|

| Operating Speed (RPM) | Below 300 RPM | 300 - 1000 RPM |

| Fuel Efficiency | Higher fuel efficiency at low speeds | Moderate fuel efficiency |

| Size and Weight | Larger and heavier | Smaller and lighter |

| Power Output | High power, suitable for large vessels | Medium power, ideal for medium-sized vessels |

| Maintenance Frequency | Lower frequency, longer intervals | Higher frequency, shorter intervals |

| Fuel Type | Heavy fuel oil (HFO), marine diesel oil (MDO) | Marine diesel oil (MDO), marine gas oil (MGO) |

| Typical Applications | Large container ships, oil tankers, bulk carriers | Coastal vessels, ferries, naval ships |

| Emissions | Higher emissions without after-treatment | Lower emissions, easier compliance with regulations |

| Initial Cost | Higher upfront cost | Lower upfront cost |

Introduction to Marine Engine Types

Slow speed engines operate at speeds below 300 RPM and are commonly used in large ships due to their high efficiency and ability to burn low-quality heavy fuel oil. Medium speed engines, running between 300 and 1000 RPM, offer a balance between fuel efficiency and power output, making them suitable for smaller vessels and auxiliary power generation. Both engine types are critical in marine propulsion, with slow speed engines dominating long-haul shipping and medium speed engines favored for flexibility and maintenance ease.

Key Differences: Slow Speed vs Medium Speed Engines

Slow speed engines typically operate below 300 RPM and are designed for fuel efficiency in large marine vessels, whereas medium speed engines run between 300 and 1000 RPM, offering a balance of power and flexibility for various industrial applications. Slow speed engines use heavy fuel oil and feature robust, low-speed pistons for durability, while medium speed engines often employ lighter fuels and more compact designs for faster response times. Maintenance intervals in slow speed engines are longer due to their simpler mechanics, contrasted with medium speed engines which require more frequent servicing to maintain performance.

Operational Principles and Design

Slow speed engines operate on a two-stroke cycle with large, heavy components designed for low RPM and high torque, making them ideal for marine propulsion and heavy-duty applications. Medium speed engines use a four-stroke cycle with lighter, more compact components to achieve higher RPMs and better fuel efficiency, suitable for power generation and smaller vessels. The design of slow speed engines emphasizes durability and fuel flexibility, while medium speed engines focus on balance between performance, efficiency, and emissions control.

Fuel Efficiency and Consumption Rates

Medium speed engines generally offer better fuel efficiency compared to slow speed engines due to higher operational speeds and optimized combustion processes. Slow speed engines consume larger volumes of fuel per unit of power output but excel in durability and lower maintenance costs for long-haul marine applications. Fuel consumption rates for medium speed engines typically range from 160 to 200 g/kWh, whereas slow speed engines often consume between 180 to 220 g/kWh, highlighting the efficiency advantage of medium speed engines in diverse industrial uses.

Maintenance Requirements and Costs

Slow speed engines demand higher maintenance due to their large size and heavier structural components, resulting in increased service intervals and labor costs. Medium speed engines, with their more compact design and advanced technology, require less frequent but more specialized maintenance, which can reduce overall downtime and expenses. Cost-efficiency in maintenance depends on operational profiles, with medium speed engines generally offering lower lifecycle costs because of quicker repairs and more accessible spare parts.

Emission Standards and Environmental Impact

Slow speed engines typically emit higher levels of nitrogen oxides (NOx) and particulate matter due to their lower combustion efficiency, making it challenging to meet the latest IMO Tier III emission standards without advanced exhaust gas cleaning systems. Medium speed engines, operating at higher speeds with more efficient combustion processes, generally produce fewer emissions and are more adaptable to cleaner fuels and aftertreatment technologies, thereby reducing their environmental impact. Regulatory compliance increasingly favors medium speed engines for maritime applications focused on minimizing greenhouse gas emissions and air pollution in sensitive areas.

Space and Weight Considerations

Slow speed engines typically have larger dimensions and higher weight due to their robust construction and lower operational speeds, making them suitable for applications where space is less constrained. Medium speed engines offer a more compact design and reduced weight, optimizing space utilization for marine vessels and power plants with limited engine room capacity. The choice between these engines often hinges on balancing the spatial footprint against performance requirements in specific operational contexts.

Performance and Reliability at Sea

Slow speed engines excel in performance and reliability at sea due to their robust design, capable of maintaining consistent power output with minimal wear over long durations. Medium speed engines offer a balance of higher operational speeds and better fuel efficiency, but may require more frequent maintenance to ensure reliability during extended voyages. Both engine types are engineered for maritime use, yet slow speed engines are preferred for their durability and low-speed torque optimal for large vessels operating under heavy load conditions.

Applications in Modern Marine Vessels

Slow speed engines dominate in large container ships and bulk carriers due to their high fuel efficiency and ability to burn heavy fuel oil, optimizing long-haul operations. Medium speed engines find extensive use in ferries, offshore supply vessels, and naval ships, offering versatility and faster startup times suitable for variable speed demands. Their adaptability enables integration with auxiliary systems, contributing to improved overall vessel performance and regulatory compliance.

Future Trends in Marine Engine Technology

Future trends in marine engine technology emphasize the shift from traditional slow speed engines, known for their high efficiency and low fuel consumption, towards medium speed engines that offer greater flexibility and quicker startup times suitable for hybrid and alternative fuel integration. Innovations in medium speed engines include enhanced fuel adaptability, such as LNG and biofuels, alongside digital monitoring systems that optimize performance and reduce emissions. The ongoing development aims to balance the slow speed engine's durability and efficiency with the medium speed engine's responsiveness and environmental compliance, driving the industry toward greener and smarter propulsion solutions.

Specific Fuel Consumption (SFC)

Medium speed engines typically achieve lower Specific Fuel Consumption (SFC) than slow speed engines, offering improved fuel efficiency in applications requiring balanced power output and operational flexibility.

Mean Effective Pressure (MEP)

Medium speed engines typically exhibit higher Mean Effective Pressure (MEP) compared to slow speed engines, resulting in improved efficiency and power output.

Bore-to-Stroke Ratio

Slow speed engines typically feature a lower bore-to-stroke ratio, resulting in longer strokes for increased torque, whereas medium speed engines have a higher bore-to-stroke ratio that supports higher rotational speeds and improved power output.

Turbocharging System

Turbocharging systems in medium speed engines enhance power output and fuel efficiency more effectively than those in slow speed engines due to their higher operational speeds and optimized air intake pressures.

Crosshead Bearing

Crosshead bearings in slow speed engines experience lower RPM and higher load per revolution, enhancing durability and reducing wear compared to medium speed engines where higher speeds increase bearing stress and maintenance requirements.

Trunk Piston Engine

Trunk piston engines in slow-speed variants deliver higher fuel efficiency and durability for marine propulsion, while medium-speed trunk piston engines offer balanced performance suited for auxiliary power and smaller vessels.

Continuous Duty Cycle

Slow speed engines provide higher torque and fuel efficiency for continuous duty cycles in heavy-duty marine and power generation applications, whereas medium speed engines offer greater flexibility and faster response times suitable for variable load conditions.

Cylinder Lubrication

Medium speed engines use more precise cylinder lubrication systems than slow speed engines, enhancing fuel efficiency and reducing wear.

Engine Foundation Design

Slow speed engine foundations require larger mass and extensive vibration isolation due to higher dynamic forces, whereas medium speed engine foundations optimize space with moderate stiffness and damping to balance performance and structural integrity.

Camshaft Configuration

Slow speed engines typically use a single camshaft located in the engine block for simplicity and durability, whereas medium speed engines often employ overhead camshaft configurations to enhance valve timing precision and performance.

slow speed engine vs medium speed engine Infographic

njnir.com

njnir.com