Dynamic positioning systems use computer-controlled thrusters to maintain a vessel's position and heading automatically, allowing precise maneuvering in deep water without anchors. Mooring systems rely on physical anchors, chains, and lines to secure a vessel, which can be less flexible and slower to adjust, especially in changing sea conditions. Dynamic positioning offers enhanced operational efficiency and safety for complex marine tasks such as drilling and diving support compared to traditional mooring.

Table of Comparison

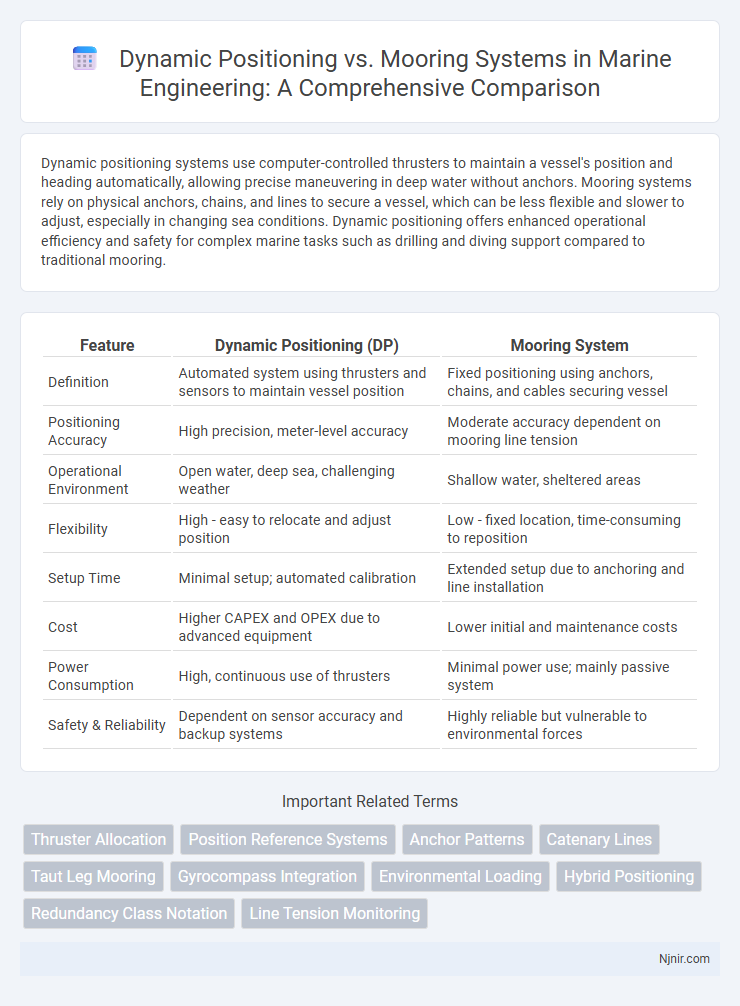

| Feature | Dynamic Positioning (DP) | Mooring System |

|---|---|---|

| Definition | Automated system using thrusters and sensors to maintain vessel position | Fixed positioning using anchors, chains, and cables securing vessel |

| Positioning Accuracy | High precision, meter-level accuracy | Moderate accuracy dependent on mooring line tension |

| Operational Environment | Open water, deep sea, challenging weather | Shallow water, sheltered areas |

| Flexibility | High - easy to relocate and adjust position | Low - fixed location, time-consuming to reposition |

| Setup Time | Minimal setup; automated calibration | Extended setup due to anchoring and line installation |

| Cost | Higher CAPEX and OPEX due to advanced equipment | Lower initial and maintenance costs |

| Power Consumption | High, continuous use of thrusters | Minimal power use; mainly passive system |

| Safety & Reliability | Dependent on sensor accuracy and backup systems | Highly reliable but vulnerable to environmental forces |

Introduction to Marine Positioning Systems

Marine positioning systems are critical technologies used to maintain vessel stability and precise location in offshore operations. Dynamic positioning (DP) employs computer-controlled thrusters and sensors to automatically keep a ship or platform at a specific position and heading, without anchors or mooring lines. Mooring systems rely on fixed anchors, chains, and lines to physically secure vessels, providing stability through mechanical means but limiting mobility and adaptability in changing marine conditions.

Fundamentals of Dynamic Positioning

Dynamic positioning relies on computer-controlled thrusters and sensors to maintain a vessel's position and heading automatically, using GPS, wind sensors, and motion reference units for real-time adjustments. In contrast, mooring systems secure a vessel using anchors, chains, and winches for physical restraint, requiring manual or semi-automated adjustments. The fundamentals of dynamic positioning involve integrating propulsion units with advanced control algorithms to counteract environmental forces without physical anchoring.

Mooring Systems Explained

Mooring systems use fixed anchors, chains, and ropes to secure vessels or offshore platforms, offering stability through physical connection to the seabed. They are essential for long-term station-keeping in environments where dynamic positioning (DP) may be less reliable due to power limitations or complex vessel operations. Mooring systems reduce fuel consumption and operational costs by minimizing thruster use, making them ideal for floating structures such as FPSOs, production platforms, and floating wind turbines.

Key Components of Dynamic Positioning

Dynamic positioning systems rely on key components such as sensors, thrusters, and a central control computer to maintain vessel position and heading automatically, using real-time data from GPS, gyrocompasses, and motion sensors. The control computer processes input from the sensors and adjusts the thrusters accordingly to counteract external forces like wind, current, and waves, enabling precise station-keeping without physical anchors. This contrasts with mooring systems that use anchors, chains, and winches to secure a vessel through mechanical means.

Types of Mooring Configurations

Mooring systems feature several configurations, including spread mooring, single-point mooring, turret mooring, and catenary mooring, each designed to stabilize vessels or offshore structures by anchoring them to the seabed. Spread mooring uses multiple anchors arranged radially, offering high stability for floating platforms; single-point mooring allows rotation around a single anchor point, commonly used in offshore loading. Turret mooring integrates a rotating turret connected to subsea anchors, enabling both positional control and rotational freedom, while catenary mooring relies on heavy chain anchors providing elasticity and shock absorption.

Operational Differences: DP vs. Mooring

Dynamic positioning (DP) systems use computerized controls and thrusters to maintain a vessel's position and heading automatically, allowing for precise station-keeping in deep or confined waters without physical anchors. Mooring systems rely on anchors, chains, or cables fixed to the seabed to hold a vessel in place, making them suitable for stable conditions but limited by water depth and seabed characteristics. DP offers greater flexibility and rapid repositioning, while mooring provides energy-efficient holding with minimal mechanical complexity under suitable environmental conditions.

Advantages of Dynamic Positioning

Dynamic positioning (DP) systems provide precise vessel stability using computer-controlled thrusters, enabling operations in deep or narrow waters where traditional mooring is impractical. Unlike mooring systems, DP offers enhanced maneuverability and rapid repositioning without reliance on seabed anchors, reducing setup time and environmental impact. Advanced sensors and GPS integration ensure superior accuracy and safety during offshore drilling, diving, and construction activities.

Benefits of Mooring Systems

Mooring systems provide reliable vessel station-keeping by securing offshore structures through anchored cables or chains, offering cost-effective stability in shallow to moderate depths compared to dynamic positioning systems. These systems reduce fuel consumption and emissions by minimizing the need for thruster use, enhancing environmental sustainability during operations. Maintenance and operational costs are typically lower, as mooring systems require less complex technology and fewer continuous power demands than dynamic positioning systems.

Applications in Marine Operations

Dynamic positioning systems are essential in offshore drilling, subsea construction, and pipeline installation, where precise vessel positioning is critical despite environmental forces. Mooring systems are widely used in stationary applications such as floating production storage and offloading units (FPSOs), offshore wind farms, and permanent platforms to provide stability over extended periods. Both technologies enhance marine operations by ensuring operational efficiency and safety in complex marine environments.

Choosing Between DP and Mooring Systems

Choosing between Dynamic Positioning (DP) and mooring systems depends on operational needs, environmental conditions, and vessel type. DP offers precise, real-time station-keeping using thrusters, ideal for deepwater or movable operations where flexibility and quick repositioning are essential. Mooring systems provide cost-effective stability using anchors or chains, better suited for fixed or semi-permanent locations with predictable seabed characteristics.

Thruster Allocation

Dynamic positioning relies on advanced thruster allocation algorithms to maintain vessel position precisely without physical anchors, contrasting with mooring systems that depend on fixed anchors and lines for stability.

Position Reference Systems

Dynamic positioning systems rely on advanced position reference systems such as DGPS, hydroacoustic beacons, and taut wire sensors to maintain vessel location, while mooring systems depend on fixed physical anchors and lines without continuous position feedback.

Anchor Patterns

Dynamic positioning uses thrusters controlled by sensors and computers for vessel stability without anchors, while mooring systems rely on fixed anchor patterns arranged in configurations such as spread, single point, or turret mooring to secure vessels.

Catenary Lines

Catenary lines in mooring systems provide passive stability by weight-induced restoring force, whereas dynamic positioning relies on active thruster control without physical anchors or lines.

Taut Leg Mooring

Taut Leg Mooring systems provide enhanced positional stability and reduced vessel movement compared to Dynamic Positioning by using pre-tensioned mooring lines that minimize environmental impact and maintenance costs.

Gyrocompass Integration

Dynamic positioning systems integrate gyrocompasses for real-time heading data to maintain vessel stability, whereas mooring systems rely less on gyrocompass input, focusing more on physical anchor positioning.

Environmental Loading

Dynamic positioning systems precisely maintain vessel position using thrusters to counteract environmental loading such as wind, waves, and currents, whereas mooring systems rely on anchors and lines to passively resist these forces.

Hybrid Positioning

Hybrid positioning combines dynamic positioning and mooring systems to enhance vessel station-keeping accuracy and operational flexibility in complex marine environments.

Redundancy Class Notation

Dynamic positioning systems with higher Redundancy Class Notation ensure superior station-keeping reliability compared to conventional mooring systems, which rely on fixed redundancy configurations.

Line Tension Monitoring

Dynamic positioning systems continuously adjust thruster output based on precise line tension monitoring to maintain vessel stability, whereas mooring systems rely on fixed anchors with tension sensors to monitor and prevent line overloads.

Dynamic positioning vs Mooring system Infographic

njnir.com

njnir.com