Scrubber systems reduce sulfur oxide emissions by using seawater or chemical solutions to wash exhaust gases, effectively lowering SOx pollutants from marine engines. Selective catalytic reduction (SCR) targets nitrogen oxides (NOx) emissions by injecting a urea-based reductant into the exhaust stream, converting NOx into nitrogen and water. Both technologies enhance environmental compliance but address different pollutants, making their combined application essential for meeting IMO Tier III standards.

Table of Comparison

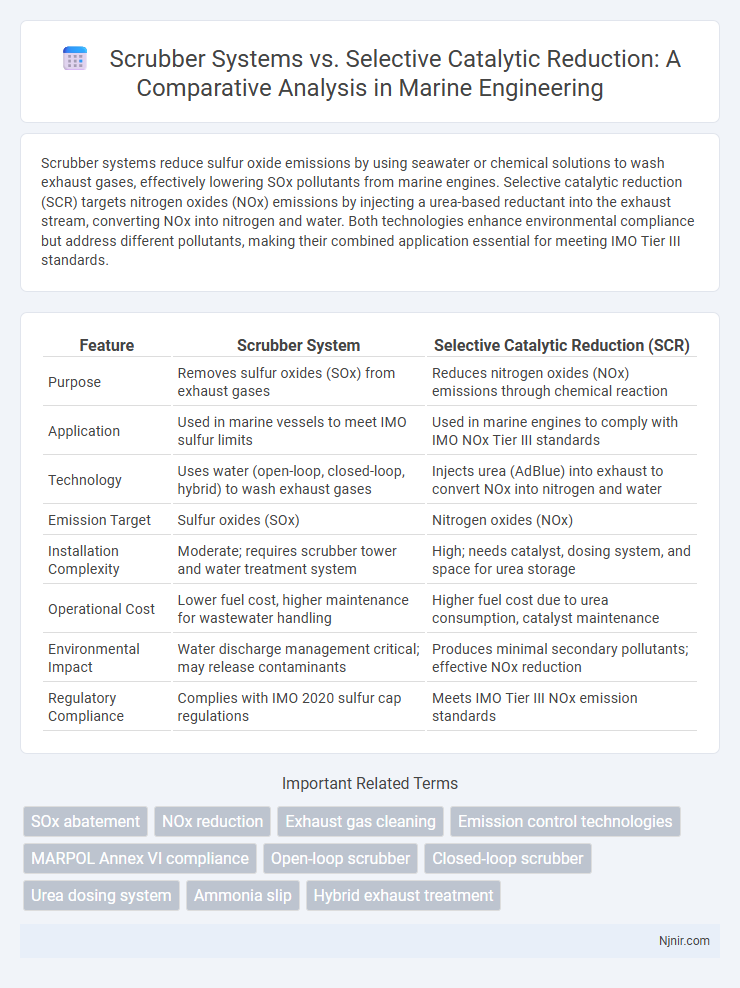

| Feature | Scrubber System | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Removes sulfur oxides (SOx) from exhaust gases | Reduces nitrogen oxides (NOx) emissions through chemical reaction |

| Application | Used in marine vessels to meet IMO sulfur limits | Used in marine engines to comply with IMO NOx Tier III standards |

| Technology | Uses water (open-loop, closed-loop, hybrid) to wash exhaust gases | Injects urea (AdBlue) into exhaust to convert NOx into nitrogen and water |

| Emission Target | Sulfur oxides (SOx) | Nitrogen oxides (NOx) |

| Installation Complexity | Moderate; requires scrubber tower and water treatment system | High; needs catalyst, dosing system, and space for urea storage |

| Operational Cost | Lower fuel cost, higher maintenance for wastewater handling | Higher fuel cost due to urea consumption, catalyst maintenance |

| Environmental Impact | Water discharge management critical; may release contaminants | Produces minimal secondary pollutants; effective NOx reduction |

| Regulatory Compliance | Complies with IMO 2020 sulfur cap regulations | Meets IMO Tier III NOx emission standards |

Introduction to Marine Emission Control Technologies

Scrubber systems and Selective Catalytic Reduction (SCR) are pivotal marine emission control technologies designed to reduce sulfur oxides (SOx) and nitrogen oxides (NOx) from ship exhaust gases. Scrubbers use seawater or freshwater to wash out SOx emissions, enabling compliance with International Maritime Organization (IMO) sulfur limits, while SCR systems inject ammonia or urea into exhaust streams to catalytically convert NOx into harmless nitrogen and water. Both technologies are critical for meeting stringent MARPOL Annex VI regulations, promoting cleaner air quality in maritime transport.

Overview of Scrubber Systems in Marine Engineering

Scrubber systems in marine engineering are exhaust gas cleaning technologies designed to remove sulfur oxides (SOx) from ship emissions, helping vessels comply with International Maritime Organization (IMO) sulfur regulations. These systems typically use seawater or freshwater mixed with chemicals to neutralize and wash out harmful pollutants from engine exhaust before release into the atmosphere. Compared to Selective Catalytic Reduction (SCR) systems, which primarily reduce nitrogen oxides (NOx) through a catalytic chemical reaction, scrubbers focus on sulfur removal and are essential for ships operating on high-sulfur fuels.

Fundamentals of Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) is an advanced emission control technology that reduces nitrogen oxides (NOx) in exhaust gases by injecting a urea-based reductant into the flue gas stream, which reacts over a catalyst to convert NOx into harmless nitrogen and water. Unlike scrubber systems that primarily remove sulfur oxides (SOx), SCR specifically targets NOx reduction, achieving efficiency rates of up to 90% in marine and industrial combustion applications. The catalyst composition, operating temperature range of 250-450degC, and precise dosing of the reductant are critical factors for optimal SCR performance and compliance with stringent emissions regulations.

Regulatory Compliance: Scrubbers vs. SCR

Scrubber systems and Selective Catalytic Reduction (SCR) both play crucial roles in meeting stringent environmental regulations for industrial emissions. Scrubbers primarily target sulfur oxides (SOx) and particulates to comply with sulfur emission limits set by the IMO 2020 and EPA standards, while SCR technology focuses on reducing nitrogen oxides (NOx) emissions, aligning with Tier III regulations under MARPOL Annex VI. Regulatory compliance often requires integrating both systems in maritime and power plants to achieve comprehensive pollutant reduction and meet multi-pollutant emission limits.

Emission Reduction Efficiency: SOx and NOx Comparison

Scrubber systems primarily target sulfur oxides (SOx) by using alkaline substances to neutralize and remove SOx from exhaust gases, achieving removal efficiencies of up to 95%. Selective Catalytic Reduction (SCR) systems specialize in reducing nitrogen oxides (NOx) through a chemical reaction with ammonia or urea in the presence of a catalyst, attaining NOx reduction rates typically between 70% and 95%. While scrubbers excel in SOx reduction, SCR technology is more effective for NOx control, making them complementary solutions for comprehensive emission abatement.

Installation and Integration Challenges

Scrubber systems demand substantial installation space and integration with existing exhaust infrastructure, often requiring significant retrofitting and downtime. Selective Catalytic Reduction (SCR) units face challenges related to precise placement near the engine for optimal temperature control and must incorporate ammonia or urea storage and injection systems. Both technologies require careful electrical and control system integration to ensure efficient operation and compliance with emission regulations.

Operational and Maintenance Considerations

Scrubber systems require regular monitoring of chemical dosing, pH levels, and slurry management to maintain efficient pollutant removal, with maintenance focused on pump and spray nozzle integrity and sludge disposal. Selective Catalytic Reduction (SCR) systems demand consistent catalyst inspection and replacement, precise injection of urea or ammonia, and management of ammonia slip to sustain NOx reduction performance. Operational challenges for scrubbers involve handling corrosive liquids and waste, while SCR systems require careful control of catalyst temperature and avoid catalyst poisoning through fuel quality management.

Environmental Impact and Byproduct Management

Scrubber systems primarily reduce sulfur oxide (SOx) emissions by using alkaline substances to neutralize acid gases, resulting in byproducts like gypsum that require careful disposal or reuse strategies to prevent environmental contamination. Selective Catalytic Reduction (SCR) targets nitrogen oxides (NOx) by converting them into nitrogen and water through a catalytic reaction with ammonia or urea, producing minimal harmful byproducts but necessitating ammonia slip control to avoid secondary pollution. Environmental impact assessments show scrubbers effectively lower acid rain precursors, whereas SCR systems excel in reducing smog-forming NOx, making their combined or site-specific application essential for comprehensive emission control.

Cost Analysis: CAPEX and OPEX Evaluation

Scrubber systems typically exhibit higher capital expenditure (CAPEX) due to the installation of complex equipment for removing sulfur oxides, while selective catalytic reduction (SCR) units tend to have moderate CAPEX focused on catalyst modules and injection systems. Operating expenses (OPEX) for scrubbers are often elevated because of continuous water treatment, reagent consumption, and sludge disposal, whereas SCR systems incur costs primarily from catalyst replacement and ammonia or urea feedstock. A comprehensive cost analysis reveals that SCR may be more cost-effective in long-term operations with stringent NOx limits, whereas scrubbers are preferred for sulfur-heavy fuel applications despite their higher initial and operational costs.

Future Trends and Technological Advancements

Scrubber systems and Selective Catalytic Reduction (SCR) technologies are evolving with advancements in sensor integration, real-time emissions monitoring, and AI-driven process optimization to meet stricter global environmental regulations. Future trends emphasize hybrid solutions combining scrubbers' sulfur oxide removal with SCR's nitrogen oxide reduction for enhanced multi-pollutant control in marine and industrial applications. Emerging materials such as advanced catalysts and corrosion-resistant coatings are improving durability and efficiency, lowering operational costs, and reducing environmental impact.

SOx abatement

Selective catalytic reduction primarily targets NOx reduction, while scrubber systems efficiently remove SOx emissions by chemically absorbing sulfur oxides from industrial exhaust gases.

NOx reduction

The scrubber system removes NOx by absorbing gases into a liquid solution, while Selective Catalytic Reduction (SCR) chemically converts NOx into nitrogen and water using a catalyst and ammonia, achieving up to 90% NOx reduction efficiency.

Exhaust gas cleaning

Selective catalytic reduction (SCR) uses a catalyst and reductant to convert NOx in exhaust gases into nitrogen and water, while scrubber systems remove sulfur oxides (SOx) and particulate matter from exhaust streams through chemical absorption and filtration processes.

Emission control technologies

Scrubber systems primarily reduce sulfur oxides (SOx) by washing exhaust gases with a liquid, while Selective Catalytic Reduction (SCR) systems target nitrogen oxides (NOx) emissions through chemical reactions using a catalyst and ammonia or urea.

MARPOL Annex VI compliance

Scrubber systems and Selective Catalytic Reduction (SCR) both reduce ship emissions to comply with MARPOL Annex VI, with scrubbers focusing on sulfur oxide (SOx) removal from exhaust gases and SCR targeting nitrogen oxide (NOx) reduction through catalytic reactions.

Open-loop scrubber

Open-loop scrubber systems reduce sulfur oxide emissions by using seawater to neutralize exhaust gases, whereas Selective Catalytic Reduction (SCR) systems target nitrogen oxides by injecting ammonia or urea and catalyzing their conversion into nitrogen and water.

Closed-loop scrubber

Closed-loop scrubbers in scrubber systems recycle purified wash water to efficiently remove sulfur oxides from ship emissions, offering a sustainable alternative to Selective Catalytic Reduction systems that target nitrogen oxides through catalyst-based chemical reactions.

Urea dosing system

The urea dosing system in Selective Catalytic Reduction precisely injects ammonia from urea to reduce NOx emissions, whereas scrubber systems primarily remove SOx using chemical absorption without urea-based dosing.

Ammonia slip

Scrubber systems reduce sulfur oxides without ammonia slip, whereas Selective Catalytic Reduction (SCR) effectively lowers nitrogen oxides but can produce ammonia slip typically ranging from 2 to 10 ppm if improperly managed.

Hybrid exhaust treatment

Hybrid exhaust treatment combines scrubber systems and selective catalytic reduction to optimize emissions control by simultaneously removing sulfur oxides and nitrogen oxides, enhancing overall air pollution reduction in marine and industrial engines.

Scrubber system vs Selective catalytic reduction Infographic

njnir.com

njnir.com