Riveted joints offer reliable mechanical fastening and ease of inspection in marine engineering but can introduce stress concentrations and require more maintenance compared to welded joints. Welded joints provide stronger, seamless connections that reduce weight and improve structural integrity, making them ideal for modern shipbuilding. However, welding demands skilled labor and careful quality control to prevent defects such as cracks and corrosion, which can compromise durability in harsh marine environments.

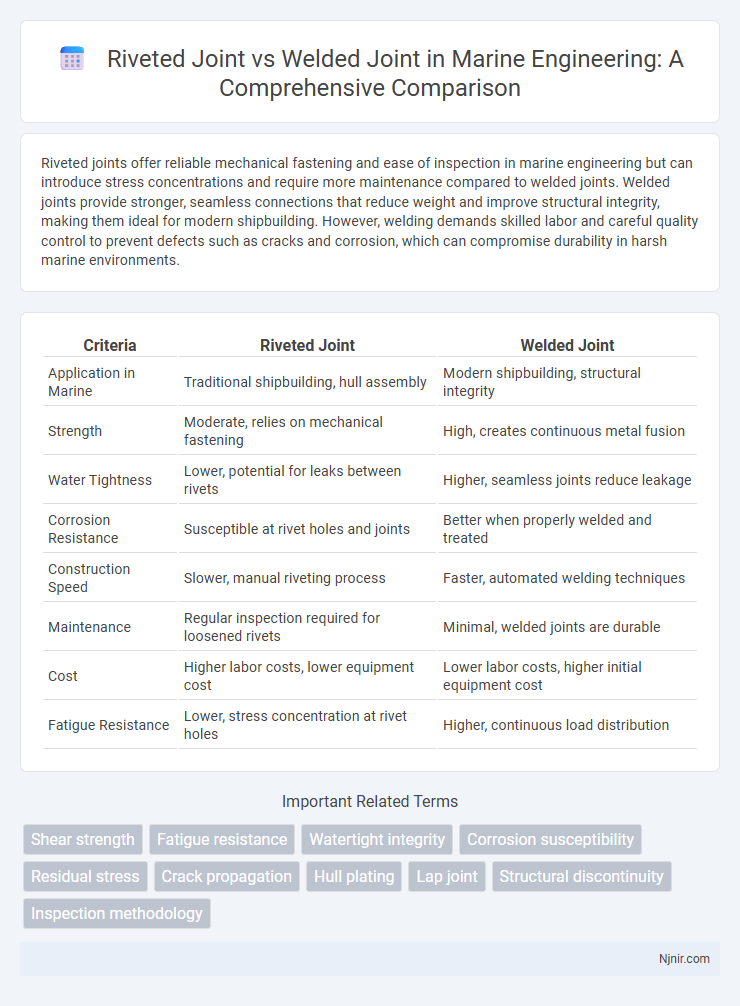

Table of Comparison

| Criteria | Riveted Joint | Welded Joint |

|---|---|---|

| Application in Marine | Traditional shipbuilding, hull assembly | Modern shipbuilding, structural integrity |

| Strength | Moderate, relies on mechanical fastening | High, creates continuous metal fusion |

| Water Tightness | Lower, potential for leaks between rivets | Higher, seamless joints reduce leakage |

| Corrosion Resistance | Susceptible at rivet holes and joints | Better when properly welded and treated |

| Construction Speed | Slower, manual riveting process | Faster, automated welding techniques |

| Maintenance | Regular inspection required for loosened rivets | Minimal, welded joints are durable |

| Cost | Higher labor costs, lower equipment cost | Lower labor costs, higher initial equipment cost |

| Fatigue Resistance | Lower, stress concentration at rivet holes | Higher, continuous load distribution |

Introduction to Marine Joint Technologies

Riveted joints in marine applications provide mechanical fastening through overlapping metal plates secured by metal pins, ensuring high shear strength and resistance to dynamic loads in ship structures. Welded joints create a continuous metal fusion between components, offering superior strength, reduced weight, and enhanced watertight integrity critical for modern shipbuilding. Marine joint technologies prioritize corrosion resistance and fatigue durability to withstand harsh ocean environments and maintain structural integrity over the vessel's lifespan.

Overview of Riveted Joints in Marine Engineering

Riveted joints in marine engineering involve fastening components using metal pins or rivets, providing reliable mechanical interlocking suitable for ship hull construction and structural frames. These joints offer excellent vibration resistance and fatigue strength in harsh marine environments, especially where thermal deformation must be minimized. Riveting remains a preferred method for assembling steel plates in shipbuilding due to its durability and ease of inspection compared to welded joints.

Fundamentals of Welded Joints in Shipbuilding

Welded joints in shipbuilding involve the fusion of metal parts through localized melting, creating a continuous and strong bond essential for structural integrity in marine environments. These joints offer superior strength, weight savings, and resistance to corrosion compared to riveted joints, which rely on mechanical fastening that can introduce stress concentrations. Understanding metallurgical effects, heat input control, and proper weld techniques is fundamental for ensuring durability and fatigue resistance in welded ship structures.

Riveted vs Welded Joints: Strength Comparison

Riveted joints provide high shear strength and are effective in applications subjected to dynamic loads, while welded joints offer superior tensile strength and better resistance to fatigue due to their continuous metal fusion. Welded joints eliminate stress concentration points found in rivet holes, enhancing overall structural integrity, especially in high-stress environments. The choice between riveted and welded joints depends on load conditions, material compatibility, and the specific requirements of the engineering application.

Fatigue Resistance in Marine Applications

Riveted joints exhibit superior fatigue resistance in marine applications due to their ability to distribute stress more evenly and accommodate slight movements caused by waves and vibrations. Welded joints, while providing a continuous bond, often develop stress concentrations and micro-cracks under cyclic loading, leading to premature fatigue failure in harsh marine environments. Selecting riveted joints enhances structural durability and reduces maintenance costs in ships and offshore platforms subjected to repetitive loading.

Corrosion Behavior of Riveted and Welded Joints

Riveted joints exhibit localized crevice corrosion due to moisture entrapment between overlapping plates, whereas welded joints are prone to heat-affected zone (HAZ) corrosion caused by microstructural changes during welding. The corrosion resistance of welded joints can be improved through post-weld heat treatment and precise control of welding parameters, which minimize residual stresses and prevent sensitization. In contrast, riveted joints require protective coatings and regular maintenance to mitigate galvanic corrosion from dissimilar metal contact at rivet holes.

Maintenance and Repair Considerations

Riveted joints require periodic inspection for loose or corroded rivets, with replacement needing partial disassembly, making repairs time-consuming. Welded joints offer easier maintenance due to their continuous metal fusion but can develop cracks or defects that require non-destructive testing and skilled welding repairs. Proper maintenance of welded joints often involves grinding and re-welding, whereas riveted joints demand careful alignment and rivet replacement for structural integrity.

Cost Analysis: Riveting vs Welding

Riveted joints typically incur higher labor costs due to the extensive manual work and time required for hole preparation, alignment, and riveting compared to welded joints, which benefit from faster automated processes and reduced labor intensity. Material costs for rivets and additional components further increase expenses, while welding primarily consumes shielding gases and electrodes that are generally less costly per joint. Maintenance and inspection costs for riveted joints also tend to be higher due to potential loosening over time, whereas welded joints offer lower long-term costs through superior joint integrity and reduced risk of failure.

Safety Implications in Marine Structures

Riveted joints offer enhanced safety in marine structures by providing visible inspection points that help detect corrosion or fatigue before failure occurs. Welded joints, while stronger and more seamless, require rigorous non-destructive testing to ensure integrity, as hidden cracks or defects can compromise safety in harsh marine environments. The choice between riveted and welded joints significantly impacts the maintenance protocols and overall safety management of marine vessels and offshore platforms.

Future Trends in Marine Joint Technology

Future trends in marine joint technology emphasize the development of advanced welded joints utilizing robotic automation and laser welding for enhanced precision and corrosion resistance. Innovations in high-strength, lightweight materials coupled with real-time structural health monitoring systems are improving the durability and safety of welded connections compared to traditional riveted joints. The shift towards greener shipbuilding practices also drives the adoption of eco-friendly welding processes that reduce emissions and material waste.

Shear strength

Riveted joints typically exhibit lower shear strength compared to welded joints due to the discontinuity and stress concentration around rivet holes.

Fatigue resistance

Riveted joints typically offer superior fatigue resistance compared to welded joints due to their ability to distribute stress more evenly and reduce the risk of crack initiation.

Watertight integrity

Welded joints provide superior watertight integrity compared to riveted joints due to their continuous, seamless bond that eliminates leak paths.

Corrosion susceptibility

Riveted joints exhibit higher corrosion susceptibility due to crevice formation and moisture accumulation compared to welded joints, which generally offer better corrosion resistance through continuous metal fusion.

Residual stress

Residual stresses in riveted joints are typically lower and more evenly distributed compared to welded joints, where high thermal gradients often induce significant tensile residual stresses that can lead to distortion and reduced fatigue life.

Crack propagation

Crack propagation in riveted joints is often slower due to stress distribution around rivets, whereas welded joints exhibit faster crack growth influenced by residual stresses and microstructural changes.

Hull plating

Riveted joints in hull plating provide flexibility and resistance to fatigue cracking, while welded joints offer superior strength and watertight integrity essential for modern ship hull construction.

Lap joint

Lap joints in riveted connections provide better vibration resistance and ease of disassembly, whereas welded lap joints offer superior strength and airtight sealing for permanent structural applications.

Structural discontinuity

Riveted joints create structural discontinuity through overlapping plates and fasteners, whereas welded joints offer a continuous metal interface with minimal disruption to structural integrity.

Inspection methodology

Inspection of riveted joints primarily involves visual examination and ultrasonic testing for looseness or cracks, while welded joints require comprehensive methods including radiographic testing, ultrasonic testing, magnetic particle inspection, and dye penetrant inspection to detect internal and surface defects.

riveted joint vs welded joint Infographic

njnir.com

njnir.com