Air lubrication systems reduce friction between the ship hull and water by creating a layer of air bubbles, enhancing fuel efficiency and lowering emissions. Hull coatings work by providing a smooth, antifouling surface that minimizes drag and prevents biofouling growth. Combining both technologies results in optimized hydrodynamic performance and significant energy savings in marine vessels.

Table of Comparison

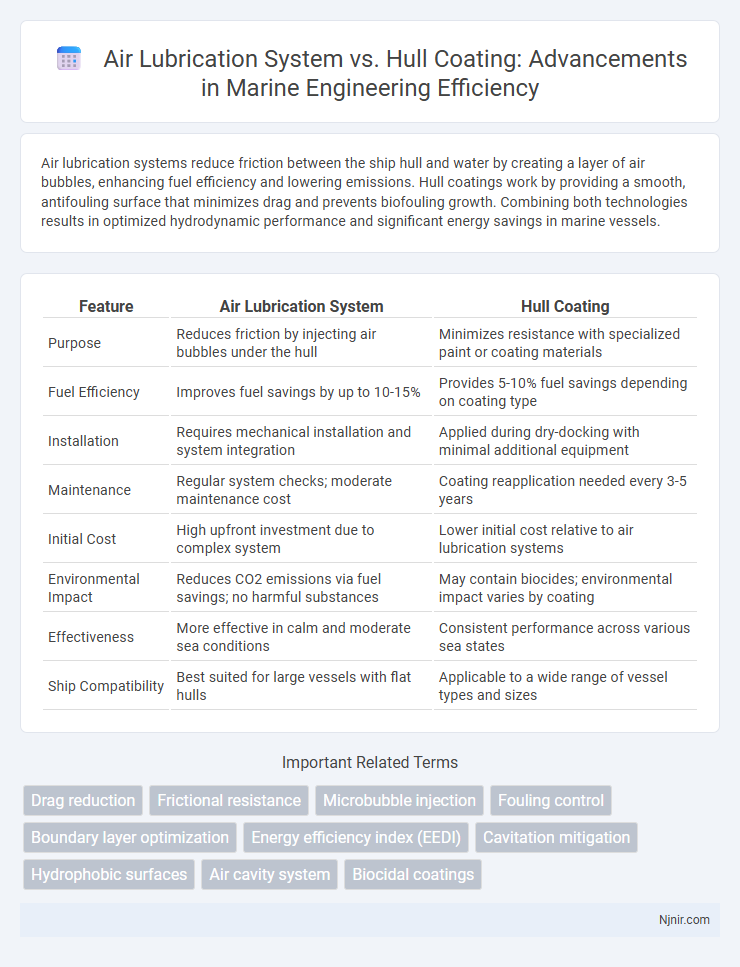

| Feature | Air Lubrication System | Hull Coating |

|---|---|---|

| Purpose | Reduces friction by injecting air bubbles under the hull | Minimizes resistance with specialized paint or coating materials |

| Fuel Efficiency | Improves fuel savings by up to 10-15% | Provides 5-10% fuel savings depending on coating type |

| Installation | Requires mechanical installation and system integration | Applied during dry-docking with minimal additional equipment |

| Maintenance | Regular system checks; moderate maintenance cost | Coating reapplication needed every 3-5 years |

| Initial Cost | High upfront investment due to complex system | Lower initial cost relative to air lubrication systems |

| Environmental Impact | Reduces CO2 emissions via fuel savings; no harmful substances | May contain biocides; environmental impact varies by coating |

| Effectiveness | More effective in calm and moderate sea conditions | Consistent performance across various sea states |

| Ship Compatibility | Best suited for large vessels with flat hulls | Applicable to a wide range of vessel types and sizes |

Introduction to Marine Energy Efficiency Technologies

Air lubrication systems reduce frictional resistance by injecting a layer of microbubbles along the hull, enhancing fuel efficiency and lowering CO2 emissions. Hull coatings use advanced low-friction or antifouling materials to minimize drag and prevent biofouling, contributing to reduced fuel consumption and maintenance costs. Both technologies play a crucial role in marine energy efficiency by optimizing vessel performance and complying with international environmental regulations.

Overview of Air Lubrication Systems

Air lubrication systems reduce ship hull friction by generating a continuous layer of microbubbles along the hull, enhancing fuel efficiency and lowering emissions. These systems release compressed air through perforated pipes or plates installed on the ship's bottom, minimizing direct water-to-hull contact and thus decreasing drag. Compared to traditional hull coatings, air lubrication offers dynamic friction reduction without degrading over time, providing sustainable performance improvements for marine vessels.

Hull Coating Solutions in Marine Engineering

Hull coating solutions in marine engineering enhance vessel performance by reducing frictional resistance and preventing biofouling, leading to improved fuel efficiency and lower maintenance costs. Advanced coatings such as silicone-based or fluoropolymer paints create smooth surfaces that inhibit marine organism attachment, preserving hull integrity and optimizing hydrodynamics. Compared to air lubrication systems that introduce air bubbles to reduce drag, hull coatings offer a passive, durable approach requiring less operational complexity and energy input.

Principles of Drag Reduction: Air vs. Coatings

Air lubrication systems reduce drag by creating a layer of microbubbles along the hull surface, decreasing water friction and enhancing vessel speed and fuel efficiency. Hull coatings minimize drag through specially formulated materials that create a smooth, hydrophobic surface, preventing biofouling and reducing surface roughness. Both technologies target frictional resistance but apply different principles: air lubrication modifies the fluid interface, while hull coatings optimize surface condition.

Installation and Maintenance Requirements

Air lubrication systems require extensive installation involving compressors, piping, and air diffusers integrated into the hull, often demanding dry-dock periods and technical expertise. Hull coatings apply a protective layer to the ship's exterior, allowing for faster installation with minimal downtime, though reapplication is needed periodically to maintain effectiveness. Maintenance of air lubrication systems involves regular checks on air supply and equipment functionality, whereas hull coatings need surface inspections and touch-ups to prevent biofouling and corrosion.

Impact on Fuel Consumption and Emissions

Air lubrication systems reduce fuel consumption by creating a layer of microbubbles along the hull, decreasing frictional resistance and improving hydrodynamic efficiency by up to 10%, which directly lowers CO2 and NOx emissions. Hull coatings minimize surface roughness and biofouling, maintaining a smooth hull and reducing drag, typically resulting in 5-15% fuel savings and corresponding emission reductions. Combining air lubrication with advanced hull coatings maximizes propulsion efficiency, leading to significant operational cost savings and enhanced compliance with maritime emission regulations.

Cost Analysis and Return on Investment

Air lubrication systems typically involve higher initial installation costs due to complex technology and integration requirements, whereas hull coatings represent a more straightforward and lower-cost application. Operational savings from air lubrication arise primarily from significant fuel efficiency improvements, often yielding a faster return on investment compared to hull coatings, which provide moderate fuel savings with longer payback periods. Comprehensive cost analysis shows that despite higher upfront expenses, air lubrication systems deliver superior long-term value through greater reductions in drag and fuel consumption.

Performance in Different Vessel Types

Air lubrication systems enhance fuel efficiency by creating a layer of air bubbles along the hull, significantly reducing friction for large container ships and bulk carriers. Hull coatings improve hydrodynamic performance by minimizing surface roughness, making them effective across various vessel types, including tankers and passenger ships. Combining both methods can optimize performance, with air lubrication favored for high-speed vessels and hull coatings providing consistent benefits for slower-moving ships.

Environmental Benefits and Drawbacks

Air lubrication systems reduce friction between the hull and water by injecting microbubbles, leading to lower fuel consumption and reduced greenhouse gas emissions, which enhances environmental sustainability. Hull coatings minimize biofouling, improving fuel efficiency and decreasing harmful emissions, though some coatings may contain biocides that pose ecological risks. Comparing both, air lubrication offers significant emission reductions without chemical pollutants, while hull coatings provide biofouling control but require careful selection to avoid environmental toxicity.

Future Trends: Hybrid and Integrated Approaches

Future trends in maritime efficiency emphasize hybrid and integrated approaches combining air lubrication systems and advanced hull coatings. These innovations enhance fuel savings and reduce emissions by optimizing friction reduction through synergistic effects on hull surfaces. Investment in smart sensors and AI-driven control systems enables real-time adaptation, maximizing performance and environmental compliance.

Drag reduction

Air lubrication systems reduce ship hull drag by creating a layer of microbubbles, achieving up to 10-15% fuel savings, while hull coatings primarily minimize friction through surface smoothness, offering 3-7% drag reduction.

Frictional resistance

Air lubrication systems reduce frictional resistance by creating a layer of microbubbles beneath the hull, while hull coatings minimize frictional resistance through smooth, low-friction surfaces that prevent biofouling.

Microbubble injection

Microbubble injection in air lubrication systems significantly reduces hull friction by creating a layer of fine bubbles that minimize water resistance, outperforming traditional hull coatings in fuel efficiency and environmental impact.

Fouling control

Air lubrication systems reduce hull fouling by creating a layer of microbubbles that minimize biofouling adhesion, while hull coatings prevent fouling through chemical or physical barrier properties applied directly to the ship's surface.

Boundary layer optimization

The air lubrication system reduces friction by generating a microbubble layer along the hull, enhancing boundary layer optimization more effectively than traditional hull coatings.

Energy efficiency index (EEDI)

Air lubrication systems reduce the Energy Efficiency Design Index (EEDI) more effectively than traditional hull coatings by minimizing frictional resistance and improving fuel efficiency in marine vessels.

Cavitation mitigation

Air lubrication systems reduce cavitation by creating a stable microbubble layer on the hull, whereas hull coatings primarily minimize cavitation damage through improved surface smoothness and corrosion resistance.

Hydrophobic surfaces

Hydrophobic hull coatings enhance vessel efficiency by minimizing water adhesion, while air lubrication systems reduce drag by generating a layer of air bubbles along the hull surface.

Air cavity system

The air cavity system enhances ship performance by creating a persistent air layer beneath the hull, reducing drag more effectively than traditional hull coating methods that rely solely on surface friction reduction.

Biocidal coatings

Air lubrication systems reduce ship hull friction by creating a layer of air bubbles, whereas biocidal hull coatings actively prevent marine organism growth using toxic substances that protect the hull from biofouling.

Air lubrication system vs Hull coating Infographic

njnir.com

njnir.com