Energy storage systems in marine engineering provide flexibility by storing excess energy for later use, enhancing ship efficiency and reducing reliance on fuel consumption. Direct drive systems, on the other hand, deliver power immediately from the engine to the propeller, offering higher mechanical efficiency and reduced maintenance complexity. Choosing between energy storage and direct drive depends on operational needs, with energy storage suited for variable power demand and direct drive ideal for consistent propulsion.

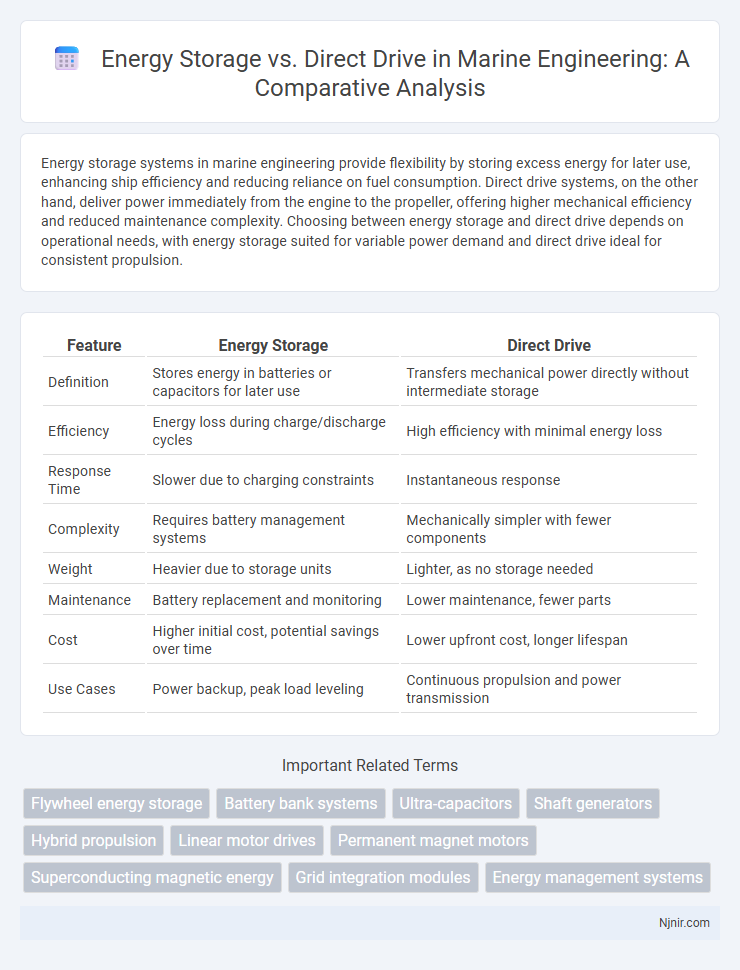

Table of Comparison

| Feature | Energy Storage | Direct Drive |

|---|---|---|

| Definition | Stores energy in batteries or capacitors for later use | Transfers mechanical power directly without intermediate storage |

| Efficiency | Energy loss during charge/discharge cycles | High efficiency with minimal energy loss |

| Response Time | Slower due to charging constraints | Instantaneous response |

| Complexity | Requires battery management systems | Mechanically simpler with fewer components |

| Weight | Heavier due to storage units | Lighter, as no storage needed |

| Maintenance | Battery replacement and monitoring | Lower maintenance, fewer parts |

| Cost | Higher initial cost, potential savings over time | Lower upfront cost, longer lifespan |

| Use Cases | Power backup, peak load leveling | Continuous propulsion and power transmission |

Introduction to Marine Energy Systems

Marine energy systems encompass technologies that harness ocean power for electricity generation, primarily through energy storage and direct drive mechanisms. Energy storage solutions in marine systems involve capturing surplus power generated by tidal or wave energy and storing it for consistent supply, enhancing grid stability. Direct drive systems eliminate intermediate gears, using permanent magnet generators to convert kinetic energy from waves or currents into electricity more efficiently and with reduced maintenance.

Overview of Energy Storage Technologies

Energy storage technologies encompass a range of solutions such as lithium-ion batteries, flow batteries, compressed air energy storage (CAES), and pumped hydro storage, each with distinct energy density, efficiency, and scalability characteristics. These systems store electrical energy for later use, enhancing grid stability and supporting renewable integration by balancing supply and demand fluctuations. Unlike direct drive systems that convert mechanical energy directly into electrical energy through rotor-stator interaction without intermediate energy storage, energy storage technologies provide temporal decoupling of energy generation and consumption.

Direct Drive Systems Explained

Direct drive systems eliminate the need for intermediate components such as gearboxes by connecting the rotor directly to the generator, enhancing efficiency and reducing maintenance costs. These systems improve energy conversion by minimizing mechanical losses, making them ideal for wind turbines and electric vehicles where reliability and performance are crucial. Compared to energy storage solutions, direct drive technology offers immediate mechanical-to-electrical power transfer, optimizing real-time energy generation without latency.

Efficiency Comparison: Energy Storage vs Direct Drive

Energy storage systems convert and store energy, often facing efficiency losses during charging and discharging cycles, typically ranging from 70% to 90%. Direct drive mechanisms eliminate intermediate energy conversions by transferring power mechanically, achieving higher efficiency rates around 90% to 95%. Comparing both, direct drive offers superior efficiency by minimizing energy loss, while energy storage provides flexibility in managing energy availability and demand.

Space and Weight Considerations

Energy storage systems often require significant space and add considerable weight due to batteries or flywheels, impacting overall design and transport efficiency. Direct drive mechanisms reduce weight by eliminating heavy gearboxes, resulting in a more compact and lighter setup ideal for applications with strict space constraints. Optimizing for minimal weight and volume favors direct drive solutions, especially in aerospace and electric vehicle industries where every kilogram and cubic centimeter counts.

Maintenance and Reliability Factors

Energy storage systems typically require regular maintenance due to battery degradation, cooling system checks, and capacity testing, impacting long-term reliability and operational costs. Direct drive technologies, with fewer moving parts and no gearbox, offer higher reliability and reduced maintenance intervals, lowering downtime and service expenses. The choice significantly affects maintenance schedules and system longevity, with direct drive favored in applications demanding high dependability and minimal upkeep.

Cost Implications and Lifecycle Analysis

Energy storage systems often involve higher upfront costs due to battery prices and integration complexities, but they provide flexibility and enable load shifting, which can reduce overall operational expenses. Direct drive technologies eliminate the need for gearboxes, lowering maintenance costs and improving reliability, resulting in longer equipment lifecycles and decreased total cost of ownership. Lifecycle analysis indicates that while energy storage may incur replacement and disposal costs, direct drive systems benefit from fewer mechanical failures and extended service intervals, optimizing long-term economic performance.

Environmental Impact Assessment

Energy storage systems reduce reliance on fossil fuels by enabling renewable energy integration and lowering greenhouse gas emissions, crucial in Environmental Impact Assessments (EIAs). Direct drive technology minimizes mechanical components, enhancing energy efficiency and reducing material usage, leading to lower environmental footprints during manufacturing and operation. Combining energy storage with direct drive solutions supports sustainable energy infrastructures and improves overall environmental performance in energy projects.

Application Suitability in Marine Vessels

Energy storage systems in marine vessels offer high flexibility for fluctuating power demands and enable efficient integration of renewable energy sources, making them suitable for hybrid and electric propulsion applications. Direct drive systems provide superior mechanical efficiency and reliability by eliminating gearbox losses, ideal for steady-state operations such as cruise ships and offshore support vessels. The choice between energy storage and direct drive depends heavily on vessel type, operational profile, and specific power management requirements.

Future Trends: Advancements in Marine Propulsion

Energy storage solutions in marine propulsion are rapidly evolving, emphasizing high-density batteries and improved energy management systems for enhanced efficiency and reduced emissions. Direct drive technology is advancing with innovations in permanent magnet motors and integrated propulsion units, offering higher reliability and lower maintenance costs. Future trends indicate a hybrid approach combining energy storage and direct drive systems to optimize performance and sustainability in marine vessels.

Flywheel energy storage

Flywheel energy storage offers high efficiency and rapid charge-discharge cycles compared to direct drive systems, making it ideal for applications requiring short-term energy buffering and grid stabilization.

Battery bank systems

Battery bank systems offer scalable, efficient energy storage solutions with rapid discharge capabilities, outperforming direct drive systems in grid stability and renewable integration.

Ultra-capacitors

Ultra-capacitors in energy storage systems offer rapid charge-discharge cycles and high power density, outperforming direct drive technologies in applications requiring quick energy bursts and extended lifecycle durability.

Shaft generators

Shaft generators provide efficient onboard energy storage by converting mechanical energy directly from the ship's propulsion shaft into electrical power, reducing reliance on separate energy storage systems like batteries.

Hybrid propulsion

Hybrid propulsion systems optimize energy efficiency by combining energy storage technologies with direct drive mechanisms to enhance performance and reduce emissions.

Linear motor drives

Linear motor drives offer higher efficiency and precise control compared to energy storage systems in direct drive applications, enhancing performance in automation and transportation sectors.

Permanent magnet motors

Permanent magnet motors in direct drive systems offer higher energy efficiency and lower maintenance compared to energy storage solutions relying on traditional mechanical components.

Superconducting magnetic energy

Superconducting magnetic energy storage (SMES) systems offer rapid energy release and high efficiency compared to direct drive systems, making them ideal for grid stabilization and power quality applications.

Grid integration modules

Grid integration modules enhance energy storage systems by providing stable power buffering, whereas direct drive systems offer more efficient mechanical-to-electrical energy conversion with reduced maintenance needs.

Energy management systems

Energy management systems optimize battery-based energy storage for load balancing and renewable integration, whereas direct drive systems enhance mechanical efficiency by eliminating gearboxes in rotating equipment.

Energy storage vs Direct drive Infographic

njnir.com

njnir.com