Dynamic positioning systems in marine engineering utilize advanced sensors and computer algorithms to maintain a vessel's exact position and heading, providing superior accuracy compared to manual positioning methods. While manual positioning relies on the skill and experience of operators adjusting thrusters and engines, dynamic systems reduce human error and enhance safety during complex operations such as offshore drilling and diving support. The integration of GPS, gyroscopes, and real-time environmental data allows dynamic positioning to adapt quickly to changing conditions, ensuring stability in challenging marine environments.

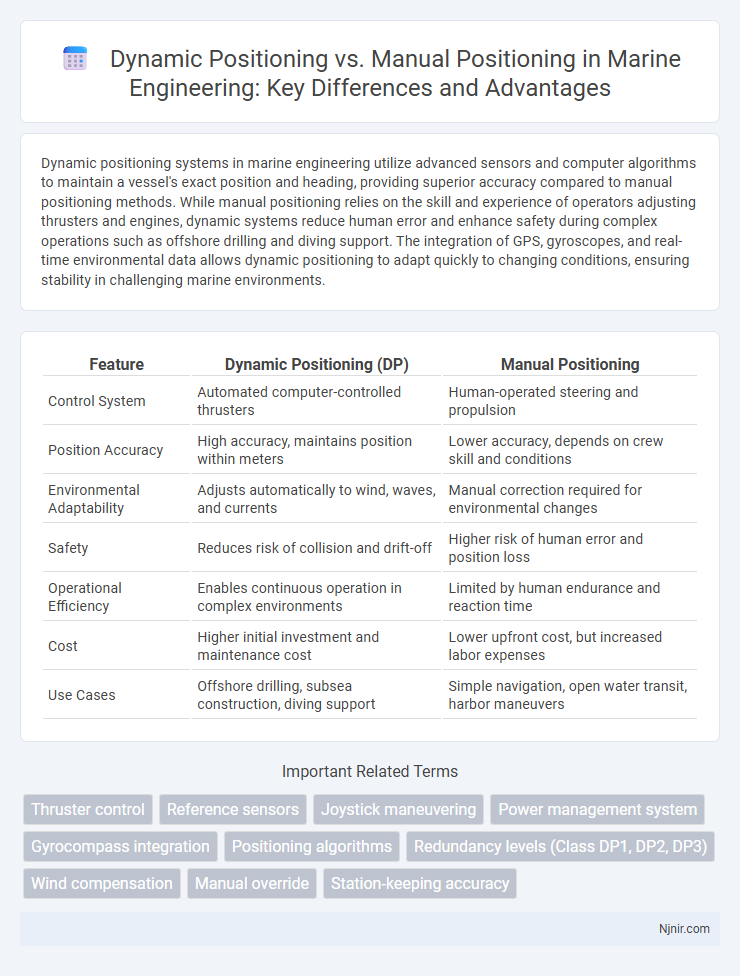

Table of Comparison

| Feature | Dynamic Positioning (DP) | Manual Positioning |

|---|---|---|

| Control System | Automated computer-controlled thrusters | Human-operated steering and propulsion |

| Position Accuracy | High accuracy, maintains position within meters | Lower accuracy, depends on crew skill and conditions |

| Environmental Adaptability | Adjusts automatically to wind, waves, and currents | Manual correction required for environmental changes |

| Safety | Reduces risk of collision and drift-off | Higher risk of human error and position loss |

| Operational Efficiency | Enables continuous operation in complex environments | Limited by human endurance and reaction time |

| Cost | Higher initial investment and maintenance cost | Lower upfront cost, but increased labor expenses |

| Use Cases | Offshore drilling, subsea construction, diving support | Simple navigation, open water transit, harbor maneuvers |

Introduction to Vessel Positioning Systems

Vessel positioning systems are critical for maritime operations, offering two primary methods: dynamic positioning (DP) and manual positioning. Dynamic positioning uses advanced computer-controlled systems and sensors, including GPS, gyroscopes, and thrusters, to maintain a vessel's position automatically despite environmental forces like wind and currents. Manual positioning relies on human operators navigating through visual references, radar, and manual controls, making it less precise and more dependent on operator skill and environmental conditions.

Fundamentals of Dynamic Positioning in Marine Engineering

Dynamic positioning (DP) systems use computer-controlled thrusters and sensors to automatically maintain a vessel's position and heading, counteracting environmental forces such as wind, waves, and currents. Manual positioning, by contrast, relies on human operators adjusting controls without automated feedback, increasing the risk of drift and inefficiency in challenging marine conditions. Fundamentals of dynamic positioning in marine engineering involve integrating GPS, gyrocompasses, and motion sensors with control algorithms to optimize vessel stability and precision during offshore operations.

Manual Positioning: Traditional Methods & Techniques

Manual positioning relies on visual cues, magnetic compasses, and mechanical controls to navigate vessels, focusing on human skill and experience. Traditional methods include dead reckoning, celestial navigation, and the use of landmarks to determine the vessel's location without electronic aid. These techniques require constant attention, detailed knowledge of navigation principles, and are often less precise compared to dynamic positioning systems.

Key Components of Dynamic Positioning Systems

Dynamic positioning systems rely on key components such as position reference systems, motion sensors, and computer control systems to maintain vessel stability and precise location automatically. Thrusters and propellers are integrated with real-time sensor data, enabling continuous adjustments to counteract environmental forces like wind and currents. Manual positioning depends on operator skill and visual cues, lacking the automated feedback loops and sensor integration that optimize accuracy in dynamic positioning systems.

Advantages of Dynamic Positioning Over Manual Positioning

Dynamic positioning systems offer superior precision and stability compared to manual positioning, enabling vessels and offshore platforms to maintain exact locations despite environmental forces like wind, waves, and currents. These systems reduce human error and operational fatigue by automating intricate control processes, resulting in enhanced safety and efficiency during critical operations such as drilling or diving support. Furthermore, dynamic positioning significantly minimizes downtime by allowing quick adjustments and continuous station-keeping without physical anchoring, improving operational continuity and cost-effectiveness.

Limitations and Challenges of Both Positioning Methods

Dynamic positioning systems face limitations such as high operational costs, complex maintenance requirements, and vulnerability to sensor failures or extreme weather conditions. Manual positioning relies heavily on operator skill and can lead to human error, inconsistent precision, and slower response times in dynamic marine environments. Both methods encounter challenges in maintaining accuracy in strong currents, limited visibility, and unpredictable sea states.

Operational Scenarios: When to Use DP vs Manual Positioning

Dynamic positioning (DP) is essential in operational scenarios requiring precise station-keeping on offshore drilling rigs, subsea construction, and floating production units under challenging sea conditions where anchor use is impractical or risky. Manual positioning is preferred for nearshore operations, vessel maneuvering in confined waterways, or when weather and sea state are mild, allowing direct human control for navigation and positioning. DP systems enhance safety and operational efficiency during complex deep-water tasks, while manual methods remain cost-effective and practical for routine or low-risk scenarios.

Safety Considerations in Vessel Positioning

Dynamic positioning systems enhance vessel safety by automatically maintaining position through thrusters and sensors, reducing human error risks. Manual positioning relies heavily on operator skill, increasing potential for mistakes during challenging environmental conditions such as strong currents or high winds. Integrating dynamic positioning technology significantly improves operational safety by providing continuous monitoring and rapid adjustments that are difficult to achieve manually.

Cost Analysis: Dynamic Positioning vs Manual Positioning

Dynamic positioning systems incur higher upfront costs due to advanced sensors, thrusters, and control software, but significantly reduce operational expenses by minimizing fuel consumption and crew requirements. Manual positioning, while less costly initially, involves increased labor costs and heightened risk of human error, which can lead to costly downtime and maintenance. Over time, dynamic positioning proves more cost-effective for complex offshore operations requiring precision and safety.

Future Trends in Marine Positioning Technology

Future trends in marine positioning technology emphasize advanced dynamic positioning (DP) systems powered by AI and machine learning algorithms to enhance precision and fuel efficiency. Integration of real-time environmental data with automated control mechanisms reduces human error inherent in manual positioning methods. Emerging innovations include hybrid systems combining satellite-based augmentation and underwater acoustic positioning for improved reliability in complex marine environments.

Thruster control

Dynamic positioning uses automated thruster control systems with real-time sensor feedback to maintain vessel position, whereas manual positioning relies on direct human input to operate thrusters without automated adjustments.

Reference sensors

Dynamic positioning relies on advanced reference sensors such as GPS, gyrocompasses, and motion sensors to maintain vessel position automatically, whereas manual positioning depends on visual or manual input without real-time sensor data integration.

Joystick maneuvering

Joystick maneuvering in dynamic positioning systems offers precise, automated vessel control compared to the skill-intensive, manual adjustments required in manual positioning.

Power management system

Dynamic positioning systems optimize power management by automatically distributing energy loads for vessel stability, whereas manual positioning relies on operator control, often resulting in less efficient power usage.

Gyrocompass integration

Dynamic positioning systems integrate gyrocompass data for precise vessel orientation, offering superior accuracy and automated control compared to manual positioning methods.

Positioning algorithms

Dynamic positioning uses advanced sensor fusion algorithms and real-time feedback control systems to automatically maintain vessel position, whereas manual positioning relies on human judgment and manual adjustments without automated algorithmic support.

Redundancy levels (Class DP1, DP2, DP3)

Dynamic positioning systems offer varying redundancy levels categorized as Class DP1 with no redundancy, Class DP2 featuring redundancy to prevent failure in a single component, and Class DP3 providing full redundancy to withstand multiple failures, unlike manual positioning which lacks such structured fault-tolerant capabilities.

Wind compensation

Dynamic positioning systems provide precise wind compensation by continuously adjusting thrusters to maintain vessel stability, whereas manual positioning relies on operator skill and slower response times, resulting in less effective wind force counteraction.

Manual override

Manual override in dynamic positioning systems enables operators to instantly regain full control of the vessel, ensuring precise navigation and safety during system failures or complex maneuvers.

Station-keeping accuracy

Dynamic positioning systems maintain station-keeping accuracy within meters by automatically compensating for environmental forces, whereas manual positioning relies on operator skill and can result in significantly less precise station-keeping.

dynamic positioning vs manual positioning Infographic

njnir.com

njnir.com