Engine derating in marine engineering involves reducing an engine's maximum output to enhance durability and fuel efficiency under specific operating conditions. Engine retrofitting, on the other hand, entails upgrading or modifying existing engine components to improve performance, comply with new emission standards, or extend service life. Choosing between derating and retrofitting depends on operational demands, regulatory requirements, and cost-benefit analysis.

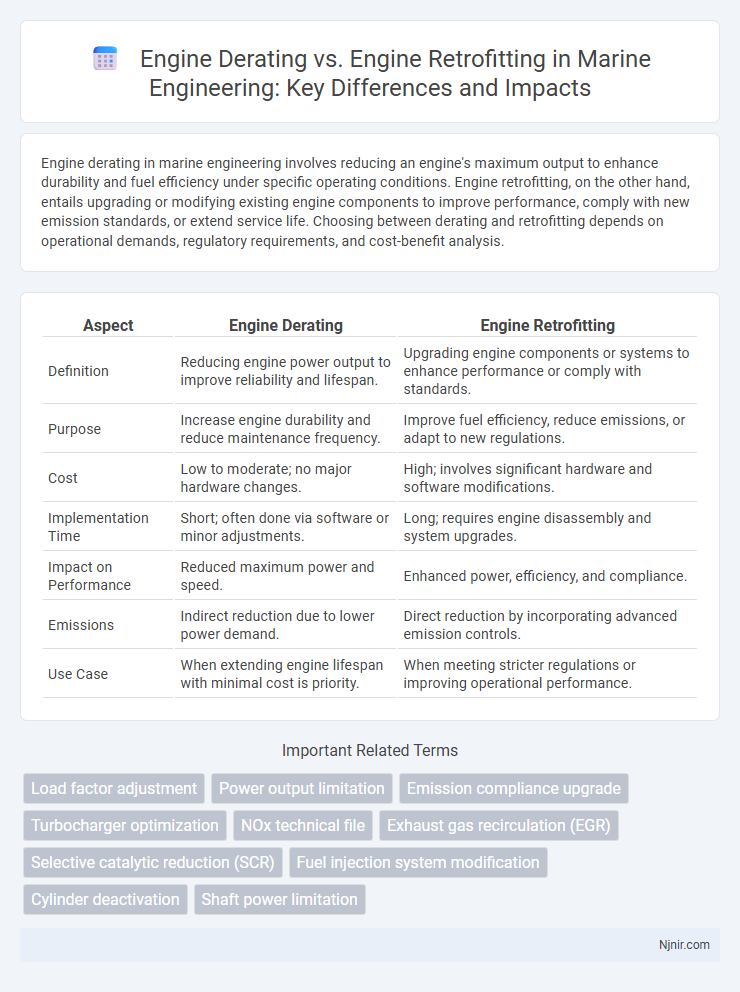

Table of Comparison

| Aspect | Engine Derating | Engine Retrofitting |

|---|---|---|

| Definition | Reducing engine power output to improve reliability and lifespan. | Upgrading engine components or systems to enhance performance or comply with standards. |

| Purpose | Increase engine durability and reduce maintenance frequency. | Improve fuel efficiency, reduce emissions, or adapt to new regulations. |

| Cost | Low to moderate; no major hardware changes. | High; involves significant hardware and software modifications. |

| Implementation Time | Short; often done via software or minor adjustments. | Long; requires engine disassembly and system upgrades. |

| Impact on Performance | Reduced maximum power and speed. | Enhanced power, efficiency, and compliance. |

| Emissions | Indirect reduction due to lower power demand. | Direct reduction by incorporating advanced emission controls. |

| Use Case | When extending engine lifespan with minimal cost is priority. | When meeting stricter regulations or improving operational performance. |

Introduction to Engine Derating and Engine Retrofitting

Engine derating involves reducing the maximum power output of an engine to enhance reliability, extend lifespan, and ensure compliance with emission standards. Engine retrofitting refers to upgrading or modifying an existing engine with advanced components or technologies to improve performance, reduce emissions, or meet regulatory requirements. Both strategies optimize engine operation but differ in approach: derating limits output, while retrofitting enhances or updates engine capabilities.

Definitions: Engine Derating vs Engine Retrofitting

Engine derating involves reducing an engine's maximum power output to enhance durability, fuel efficiency, or comply with emission standards, without altering the engine's core mechanical components. Engine retrofitting refers to the process of upgrading or modifying an existing engine with new technologies or parts to improve performance, emissions, or meet updated regulatory requirements. Both approaches aim to optimize engine functionality but differ in implementation, with derating focusing on operational limits and retrofitting on hardware or software enhancements.

Key Differences Between Derating and Retrofitting

Engine derating involves reducing an engine's maximum power output to enhance durability and meet emission standards, while engine retrofitting entails upgrading or modifying engine components to improve performance, efficiency, or compliance. Derating primarily targets longevity and regulatory adherence by limiting stress and thermal loads, whereas retrofitting focuses on integrating advanced technologies such as fuel injection systems or emission control devices. The key difference lies in derating's passive reduction of capacity versus retrofitting's active enhancement or replacement of engine parts for optimized operational capabilities.

Regulatory Compliance and Emission Standards

Engine derating reduces engine power output to meet regulatory compliance by lowering emissions, often resulting in improved fuel efficiency and extended engine lifespan. Engine retrofitting involves upgrading or modifying existing engines with emission control technologies such as diesel particulate filters (DPFs) or selective catalytic reduction (SCR) systems to comply with stricter emission standards. Both strategies aim to meet evolving environmental regulations, with derating being a simpler approach while retrofitting offers a more comprehensive solution to achieve higher emission reductions.

Technical Considerations for Engine Derating

Engine derating involves reducing the maximum power output to enhance reliability and extend engine life, often by adjusting fuel delivery or engine control parameters. This approach minimizes thermal and mechanical stress, improving durability without major hardware changes. Engine retrofitting, in contrast, requires installing updated components or systems to enhance performance or meet emission standards, which involves more complex modifications and potential downtime.

Technical Considerations for Engine Retrofitting

Engine retrofitting involves upgrading or modifying existing engine components to improve performance, emissions, and fuel efficiency, which requires detailed assessment of compatibility with current engine architecture and control systems. Technical considerations include evaluating engine structural integrity, calibration of electronic control units (ECUs), integration of advanced fuel injection or after-treatment technologies, and ensuring compliance with environmental regulations. Proper retrofitting can extend engine lifespan and optimize operational parameters without the power loss typically associated with engine derating, where engine output is intentionally reduced to prevent overstressing.

Cost Implications: Derating vs Retrofitting

Engine derating reduces operating costs by lowering fuel consumption and extending engine lifespan, making it a cost-effective solution for managing aging engines. Engine retrofitting involves significant upfront investment in new components or systems but can improve performance and compliance with emissions regulations, potentially leading to long-term savings through enhanced efficiency and reduced penalties. Comparing costs, derating offers immediate savings with minimal capital expenditure, while retrofitting requires higher initial costs balanced by future operational benefits.

Impact on Vessel Performance and Efficiency

Engine derating reduces the engine's maximum power output, improving fuel efficiency and lowering emissions but potentially limiting vessel speed and operational flexibility. Engine retrofitting involves upgrading or replacing components to enhance performance, often leading to better fuel consumption, reduced emissions, and extended engine life without compromising vessel speed. Both methods aim to optimize vessel efficiency, with derating focusing on power limitation and retrofitting emphasizing technological improvement.

Case Studies: Successful Derating and Retrofitting Projects

Case studies reveal that engine derating projects, such as the retrofit of marine diesel engines on container ships, achieve significant fuel savings and emissions reduction by operating at lower power outputs while maintaining reliability. Retrofitting examples, like the installation of advanced turbochargers and electronic fuel injection systems on aging industrial engines, demonstrate improved performance and compliance with stricter environmental regulations. Both approaches highlight the importance of customized engineering solutions to extend engine lifespan and optimize operational efficiency in commercial and industrial applications.

Future Trends in Marine Engine Optimization

Engine retrofitting incorporates advanced technologies like hybrid power systems and emissions control devices to enhance fuel efficiency and meet stricter International Maritime Organization (IMO) regulations. Engine derating reduces maximum power output to improve engine longevity and lower fuel consumption, supporting sustainability goals in shipping operations. Future trends emphasize integrating digital monitoring systems with retrofitting solutions to optimize performance and achieve carbon-neutral maritime transport.

Load factor adjustment

Engine derating involves reducing maximum power output to improve load factor efficiency, while engine retrofitting upgrades components to enhance performance without lowering load capacity.

Power output limitation

Engine derating reduces power output by permanently limiting maximum engine capacity, while engine retrofitting enhances or restores power output by upgrading components.

Emission compliance upgrade

Engine retrofitting offers a more effective emission compliance upgrade by incorporating advanced exhaust after-treatment technologies, whereas engine derating primarily reduces emissions through power output limitation without hardware modifications.

Turbocharger optimization

Turbocharger optimization enhances engine performance by improving air intake efficiency, offering a more cost-effective and scalable solution compared to engine derating and retrofitting, which involve reducing engine power or extensive hardware modifications.

NOx technical file

Engine derating reduces NOx emissions by lowering engine output to comply with regulations, while engine retrofitting uses advanced after-treatment technologies to directly reduce NOx levels without compromising performance, both essential for maintaining NOx compliance in technical files.

Exhaust gas recirculation (EGR)

Engine retrofitting with advanced Exhaust Gas Recirculation (EGR) systems significantly reduces NOx emissions compared to engine derating, which lowers engine performance to meet emission standards without optimizing combustion efficiency.

Selective catalytic reduction (SCR)

Engine retrofitting with Selective Catalytic Reduction (SCR) systems reduces emissions more effectively than engine derating by enhancing NOx conversion efficiency without compromising engine power output.

Fuel injection system modification

Engine derating reduces power output to improve reliability without major component changes, while engine retrofitting with fuel injection system modification enhances combustion efficiency and reduces emissions by upgrading existing injectors or installing advanced electronic control units.

Cylinder deactivation

Cylinder deactivation in engine derating reduces fuel consumption and emissions by disabling select cylinders, while engine retrofitting updates existing engines with improved cylinder deactivation technology to enhance performance and efficiency without full engine replacement.

Shaft power limitation

Engine derating limits shaft power by reducing engine output to extend lifespan, whereas engine retrofitting enhances or restores shaft power by upgrading components to meet performance requirements.

Engine derating vs Engine retrofitting Infographic

njnir.com

njnir.com