Traditional shaft alignment relies on mechanical tools like dial indicators and straight edges, which can be time-consuming and prone to human error in marine engineering applications. Laser shaft alignment offers high precision with digital measurements, reducing downtime and increasing the accuracy of turbine, pump, and propeller shaft alignments. This modern technique ensures optimal performance and extended equipment lifespan by minimizing misalignment-related vibrations and wear.

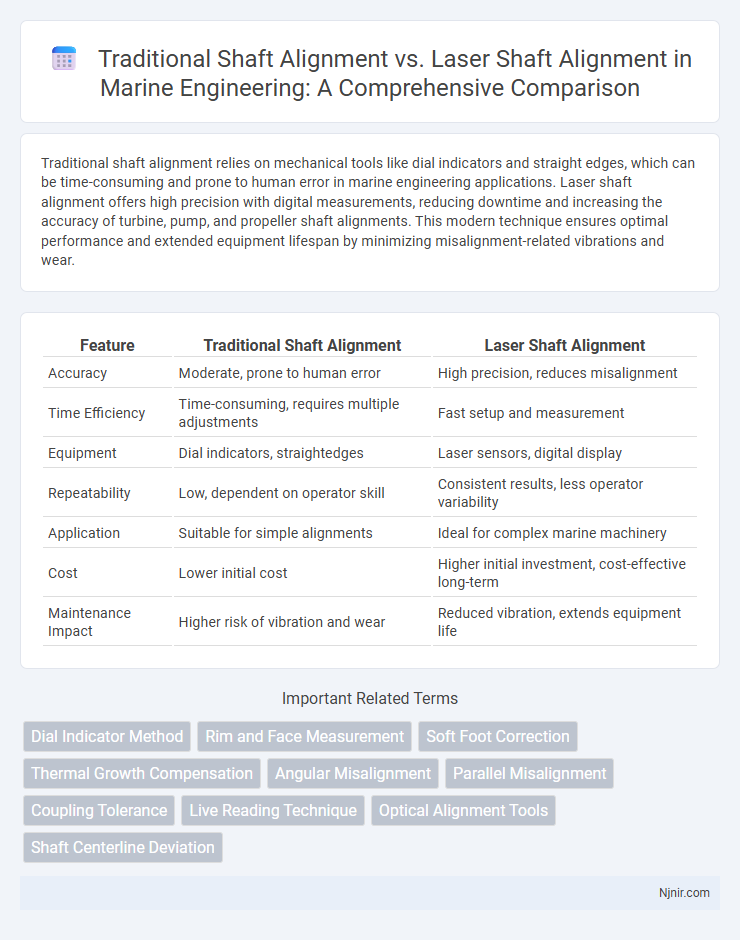

Table of Comparison

| Feature | Traditional Shaft Alignment | Laser Shaft Alignment |

|---|---|---|

| Accuracy | Moderate, prone to human error | High precision, reduces misalignment |

| Time Efficiency | Time-consuming, requires multiple adjustments | Fast setup and measurement |

| Equipment | Dial indicators, straightedges | Laser sensors, digital display |

| Repeatability | Low, dependent on operator skill | Consistent results, less operator variability |

| Application | Suitable for simple alignments | Ideal for complex marine machinery |

| Cost | Lower initial cost | Higher initial investment, cost-effective long-term |

| Maintenance Impact | Higher risk of vibration and wear | Reduced vibration, extends equipment life |

Introduction to Shaft Alignment in Marine Engineering

Shaft alignment in marine engineering ensures the precise positioning of the propulsion shaft, vital for minimizing vibration, wear, and energy loss. Traditional shaft alignment relies on mechanical tools such as dial indicators and feeler gauges, which are time-consuming and prone to human error. Laser shaft alignment employs advanced optical technology, delivering higher accuracy, faster measurements, and improved reliability crucial for maintaining marine engine performance and prolonging equipment lifespan.

Importance of Proper Shaft Alignment at Sea

Proper shaft alignment is critical for maintaining the efficiency and safety of marine vessels, reducing vibration, wear, and the risk of costly breakdowns at sea. Traditional shaft alignment methods, while widely used, often lack the precision and speed provided by laser shaft alignment systems, which employ advanced optical technology for highly accurate measurements. Laser alignment improves operational reliability and engine performance, minimizing downtime and extending the lifespan of propulsion components essential for uninterrupted maritime operations.

Overview of Traditional Shaft Alignment Methods

Traditional shaft alignment methods primarily utilize dial indicators and straightedges to measure misalignment between rotating shafts, relying on mechanical contact and manual readings. These techniques often require significant time and skill to achieve accurate alignment, with increased potential for human error and variability in results. Despite their limitations, traditional methods remain widely used in industries with legacy equipment due to lower upfront costs and established protocols.

Principles and Processes of Laser Shaft Alignment

Laser shaft alignment utilizes precise laser beams and sensors to measure the relative positions of rotating machinery shafts, enabling highly accurate alignment corrections. It operates on the principle of detecting angular and offset misalignments through real-time laser feedback, reducing human error and improving alignment speed compared to traditional dial indicator methods. The process involves mounting laser transmitters and receivers on shafts, capturing alignment data digitally, and using specialized software to guide incremental adjustments for optimal shaft coupling.

Accuracy and Reliability: Traditional vs Laser Techniques

Traditional shaft alignment methods rely on dial indicators and manual adjustments, often resulting in lower accuracy due to human error and limited resolution. Laser shaft alignment employs precise laser beams and sensors, providing highly accurate measurements with minimal operator influence, significantly improving alignment reliability. This enhanced precision in laser techniques reduces equipment wear, maintenance costs, and downtime, offering a superior alignment solution compared to traditional methods.

Efficiency and Time Considerations in Both Methods

Traditional shaft alignment relies on manual tools such as dial indicators and straightedges, which often result in longer setup and measurement times due to the need for frequent adjustments and multiple readings. Laser shaft alignment employs advanced laser technology to deliver precise measurements quickly, significantly reducing downtime and improving alignment accuracy. Efficiency gains from laser methods stem from automated data collection and real-time feedback, enabling faster decision-making and minimizing operational disruptions.

Equipment and Resource Requirements

Traditional shaft alignment relies on dial indicators, micrometers, and mechanical tools, requiring skilled technicians with extensive training to ensure precision. Laser shaft alignment uses advanced laser transmitters, receivers, and digital readouts, significantly reducing the need for manual adjustments and minimizing measurement errors. Laser systems offer faster setup, real-time data analysis, and fewer resource demands, enhancing productivity compared to conventional methods.

Impact on Vessel Performance and Maintenance

Traditional shaft alignment methods rely on visual and mechanical measurements that can lead to less precise alignment, increasing vibration levels and causing premature wear on bearings and seals, which negatively affects vessel performance and increases maintenance frequency. Laser shaft alignment uses high-precision laser technology to achieve exact alignment, significantly reducing shaft misalignment, minimizing vibration, and improving fuel efficiency and operational reliability. The enhanced accuracy of laser alignment results in lower maintenance costs, extended equipment lifespan, and optimized vessel performance through reduced downtime and improved propulsion system efficiency.

Cost Comparison: Short-term and Long-term Perspectives

Traditional shaft alignment incurs lower initial costs due to basic tools and less expensive equipment, making it suitable for companies with limited budgets. Laser shaft alignment requires higher upfront investment in precision instruments but reduces long-term expenses by minimizing machine downtime, maintenance costs, and extending equipment lifespan. Over time, the improved accuracy and efficiency of laser alignment typically result in greater cost savings and operational reliability compared to traditional methods.

Future Trends in Marine Shaft Alignment Technology

Laser shaft alignment is increasingly favored in marine applications due to its precision, speed, and ability to reduce hull vibrations and equipment wear. Future trends in marine shaft alignment technology emphasize smart sensors, IoT integration, and augmented reality tools to provide real-time data and predictive maintenance capabilities. These advancements aim to enhance operational efficiency, reduce downtime, and support sustainability in maritime operations.

Dial Indicator Method

The Dial Indicator Method in traditional shaft alignment offers cost-effective, manual precision but lacks the speed, accuracy, and ease of use provided by modern laser shaft alignment systems.

Rim and Face Measurement

Laser shaft alignment provides more precise rim and face measurements than traditional methods by using advanced sensors to detect minute misalignments, enhancing equipment performance and reducing maintenance costs.

Soft Foot Correction

Laser shaft alignment significantly improves Soft Foot Correction accuracy by providing precise measurements and real-time adjustments compared to traditional shaft alignment methods.

Thermal Growth Compensation

Laser shaft alignment provides precise Thermal Growth Compensation by accurately measuring and adjusting for the expansion of components due to temperature changes, unlike traditional methods that often lack this dynamic adaptability.

Angular Misalignment

Laser shaft alignment provides precise detection and correction of angular misalignment in rotating machinery, significantly improving maintenance accuracy compared to traditional techniques.

Parallel Misalignment

Laser shaft alignment provides more precise detection and correction of parallel misalignment compared to traditional methods, reducing machine wear and increasing operational efficiency.

Coupling Tolerance

Laser shaft alignment offers significantly higher coupling tolerance precision compared to traditional shaft alignment methods, reducing misalignment-related wear and improving equipment lifespan.

Live Reading Technique

Laser shaft alignment using live reading technique provides real-time, high-precision angular and parallel misalignment data, significantly improving accuracy and reducing downtime compared to traditional shaft alignment methods.

Optical Alignment Tools

Laser shaft alignment offers higher precision and faster setup compared to traditional optical shaft alignment tools, significantly reducing downtime and improving machinery reliability.

Shaft Centerline Deviation

Laser shaft alignment reduces Shaft Centerline Deviation by up to 90% compared to traditional methods, ensuring precise machine performance and extended equipment lifespan.

Traditional shaft alignment vs laser shaft alignment Infographic

njnir.com

njnir.com