Ultrasonic antifouling utilizes high-frequency sound waves to prevent marine organism growth on ship hulls without harmful chemicals, offering an environmentally friendly solution. Electrochlorination generates chlorine on-site to inhibit biofouling but may impact surrounding marine ecosystems due to residual chlorine release. Choosing between these methods depends on maintenance cost, environmental regulations, and operational efficiency requirements in marine engineering applications.

Table of Comparison

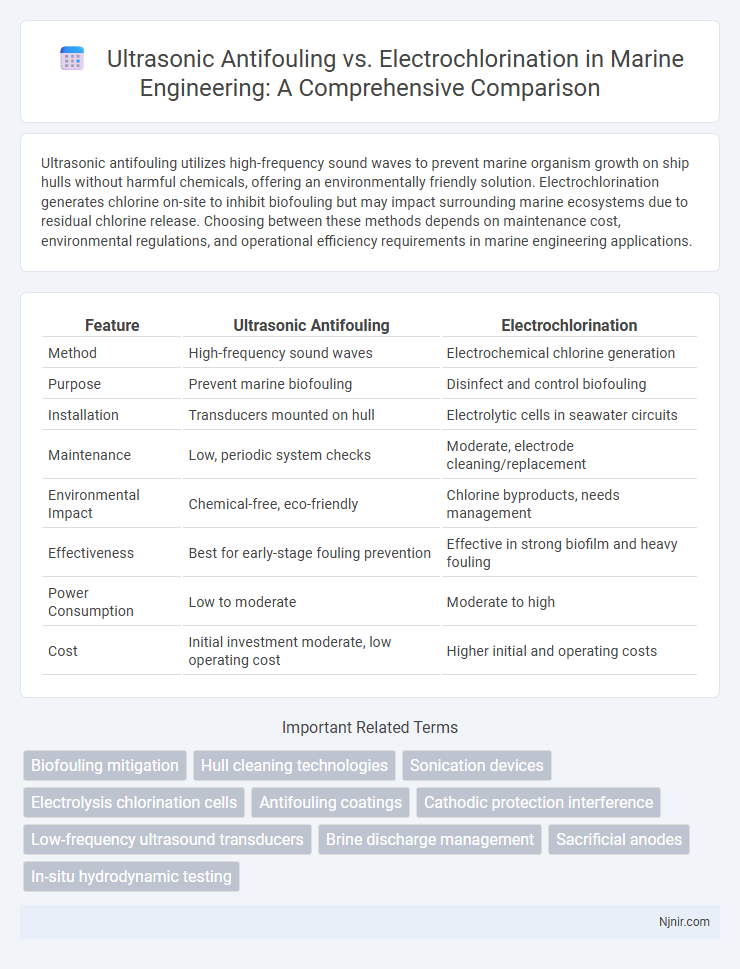

| Feature | Ultrasonic Antifouling | Electrochlorination |

|---|---|---|

| Method | High-frequency sound waves | Electrochemical chlorine generation |

| Purpose | Prevent marine biofouling | Disinfect and control biofouling |

| Installation | Transducers mounted on hull | Electrolytic cells in seawater circuits |

| Maintenance | Low, periodic system checks | Moderate, electrode cleaning/replacement |

| Environmental Impact | Chemical-free, eco-friendly | Chlorine byproducts, needs management |

| Effectiveness | Best for early-stage fouling prevention | Effective in strong biofilm and heavy fouling |

| Power Consumption | Low to moderate | Moderate to high |

| Cost | Initial investment moderate, low operating cost | Higher initial and operating costs |

Introduction to Marine Biofouling Challenges

Marine biofouling, the unwanted accumulation of microorganisms, algae, and barnacles on submerged surfaces, leads to significant operational inefficiencies and increased fuel consumption in vessels. Ultrasonic antifouling employs high-frequency sound waves to disrupt biofouling formation by targeting larval settlement and microbial colonization. Electrochlorination combats fouling through in-situ generation of chlorine, effectively sterilizing surfaces and preventing organism growth in marine environments.

Overview of Ultrasonic Antifouling Technology

Ultrasonic antifouling technology employs high-frequency sound waves to prevent biofouling by disrupting the settlement and growth of marine organisms on submerged surfaces, enhancing vessel efficiency and reducing maintenance costs. This method leverages piezoelectric transducers to generate ultrasonic vibrations that create microbubbles and cavitation, effectively inhibiting algae, barnacles, and mussels without the use of harmful chemicals. Compared to electrochlorination, ultrasonic antifouling offers an eco-friendly, low-maintenance alternative with minimal impact on aquatic ecosystems and energy consumption.

Principles Behind Electrochlorination in Marine Applications

Electrochlorination in marine applications generates chlorine by electrolyzing seawater, producing sodium hypochlorite and other chlorine compounds that prevent biofouling on ship hulls and submerged structures. This process disrupts microbial cells and inhibits the growth of barnacles, algae, and other marine organisms, maintaining vessel efficiency and reducing maintenance costs. Unlike ultrasonic antifouling, which uses sound waves to deter marine growth, electrochlorination relies on chemical biocides generated in-situ for continuous antifouling protection.

Effectiveness of Ultrasonic Antifouling Systems

Ultrasonic antifouling systems inhibit biofouling by emitting high-frequency sound waves that disrupt the adhesion and growth of marine organisms on submerged surfaces, showing up to 70-90% effectiveness in reducing fouling layers. These systems are environmentally friendly, requiring no chemicals or biocides, contrasting with electrochlorination, which uses chlorine generated electrically to kill organisms but can harm marine ecosystems due to residual chlorine. Studies indicate ultrasonic antifouling offers long-term maintenance cost savings and sustained surface protection, especially in sensitive aquatic environments.

Performance Metrics of Electrochlorination Solutions

Electrochlorination solutions demonstrate superior biofouling control by generating in-situ chlorine through electrolysis, maintaining consistent disinfection levels with residual oxidants that prevent microbial regrowth. Key performance metrics include the free available chlorine concentration, typically maintained between 0.2-0.5 mg/L for optimal efficacy, and the system's ability to self-regulate based on water quality parameters such as salinity and temperature. These systems exhibit high reliability with minimal chemical handling, low operational costs, and scalability for large-scale industrial and marine applications compared to ultrasonic antifouling methods.

Environmental Impact: Ultrasonic vs Electrochlorination

Ultrasonic antifouling technology prevents biofouling by emitting high-frequency sound waves that disrupt microorganism attachment without introducing chemicals, resulting in minimal environmental impact and zero harmful residues. In contrast, electrochlorination generates chlorine through electrolysis, effectively controlling biofouling but producing chlorinated byproducts that can harm aquatic ecosystems and contribute to chemical pollution. The ultrasonic method offers a sustainable alternative by preserving marine biodiversity and reducing the ecological footprint compared to the chemical-dependent electrochlorination process.

Installation and Maintenance Requirements

Ultrasonic antifouling systems require minimal installation efforts, typically involving the placement of transducers on hull surfaces without altering existing plumbing or electrical systems. Maintenance for ultrasonic units is low, primarily consisting of routine checks and occasional cleaning of transducers to ensure optimal performance. In contrast, electrochlorination requires more complex installation with integration into water circulation systems, electrical connections, and chemical handling equipment, leading to higher maintenance demands such as regular monitoring of chlorine generation and system calibration.

Cost Comparison: Initial and Operational Expenses

Ultrasonic antifouling systems typically involve higher initial equipment costs due to advanced transducer and signal generation technology, but they benefit from low operational expenses since they require minimal maintenance and no chemicals. Electrochlorination systems generally have moderate initial setup costs, including chlorination generators and salt dosing equipment, but incur higher ongoing expenses related to chemical consumption, electrode replacement, and energy use. Over time, ultrasonic antifouling may offer better cost efficiency for facilities seeking reduced chemical handling and maintenance budgets, while electrochlorination suits environments prioritizing proven biocide efficacy despite higher operational costs.

Suitability for Different Marine Vessel Types

Ultrasonic antifouling systems are highly suitable for smaller vessels and recreational boats due to their low maintenance and chemical-free operation, effectively preventing biofouling through high-frequency sound waves. Electrochlorination is more appropriate for large commercial vessels and offshore platforms, offering robust and continuous biofouling control by generating chlorine on-site which targets a wide range of marine organisms. Both technologies require vessel size, operational environment, and biofouling severity considerations to optimize performance and cost efficiency.

Future Trends in Marine Antifouling Technologies

Ultrasonic antifouling leverages high-frequency sound waves to disrupt biofilm formation and prevent marine organism attachment, showing promise in eco-friendly biofouling control with minimal chemical use. Electrochlorination generates chlorine in situ to inhibit fouling organisms, offering robust protection but raising concerns about environmental impacts and potential corrosion. Future trends emphasize hybrid systems integrating ultrasonic and electrochlorination technologies, enhanced AI-driven monitoring for real-time biofouling detection, and advancements in biodegradable antifouling coatings to balance effectiveness with environmental sustainability.

Biofouling mitigation

Ultrasonic antifouling uses high-frequency sound waves to disrupt biofilm formation and prevent biofouling, while electrochlorination generates chlorine electrochemically to kill biofouling organisms and inhibit their growth effectively.

Hull cleaning technologies

Ultrasonic antifouling uses high-frequency sound waves to prevent marine growth on hulls by disrupting organism attachment, while electrochlorination generates chlorine in seawater to chemically inhibit fouling, offering distinct hull cleaning efficiency and environmental impact profiles.

Sonication devices

Sonication devices in ultrasonic antifouling use high-frequency sound waves to prevent biofilm formation, offering a chemical-free alternative to electrochlorination systems that rely on chlorine generation to control marine fouling.

Electrolysis chlorination cells

Electrolysis chlorination cells in electrochlorination systems generate chlorine on-site for antifouling by electrolyzing seawater, offering efficient, low-maintenance biofouling control compared to ultrasonic antifouling technology.

Antifouling coatings

Ultrasonic antifouling uses high-frequency sound waves to prevent biofouling on coatings, while electrochlorination relies on chlorine generation to inhibit marine growth, making ultrasonic systems more compatible with eco-friendly antifouling coatings.

Cathodic protection interference

Ultrasonic antifouling systems minimize cathodic protection interference by using high-frequency sound waves to prevent biofouling without altering water chemistry, whereas electrochlorination can disrupt cathodic protection effectiveness due to chlorine generation causing accelerated metal corrosion.

Low-frequency ultrasound transducers

Low-frequency ultrasound transducers in ultrasonic antifouling systems effectively prevent biofouling by disrupting microorganism adhesion, while electrochlorination relies on generating chlorine through electrolysis to chemically inhibit marine growth.

Brine discharge management

Ultrasonic antifouling minimizes environmental impact by eliminating brine discharge, whereas electrochlorination requires careful brine discharge management to prevent marine ecosystem disruption.

Sacrificial anodes

Ultrasonic antifouling reduces biofouling through high-frequency sound waves without sacrificial anodes, while electrochlorination relies on sacrificial anodes to generate chlorine for corrosion and fouling control.

In-situ hydrodynamic testing

In-situ hydrodynamic testing demonstrates that Ultrasonic antifouling offers targeted biofilm disruption with minimal chemical impact, whereas Electrochlorination provides broad-spectrum microbial control but increases corrosion risk.

Ultrasonic antifouling vs Electrochlorination Infographic

njnir.com

njnir.com