Pod drives offer enhanced maneuverability and increased fuel efficiency compared to conventional shaft drives by integrating the motor directly into the pod, which reduces energy loss and improves thrust control. Conventional shaft drives, while simpler and more robust, often suffer from higher maintenance requirements and lower hydrodynamic efficiency due to the extended shaft and rudder configuration. The choice between pod drive and conventional shaft drive depends on vessel size, operational profile, and desired performance characteristics.

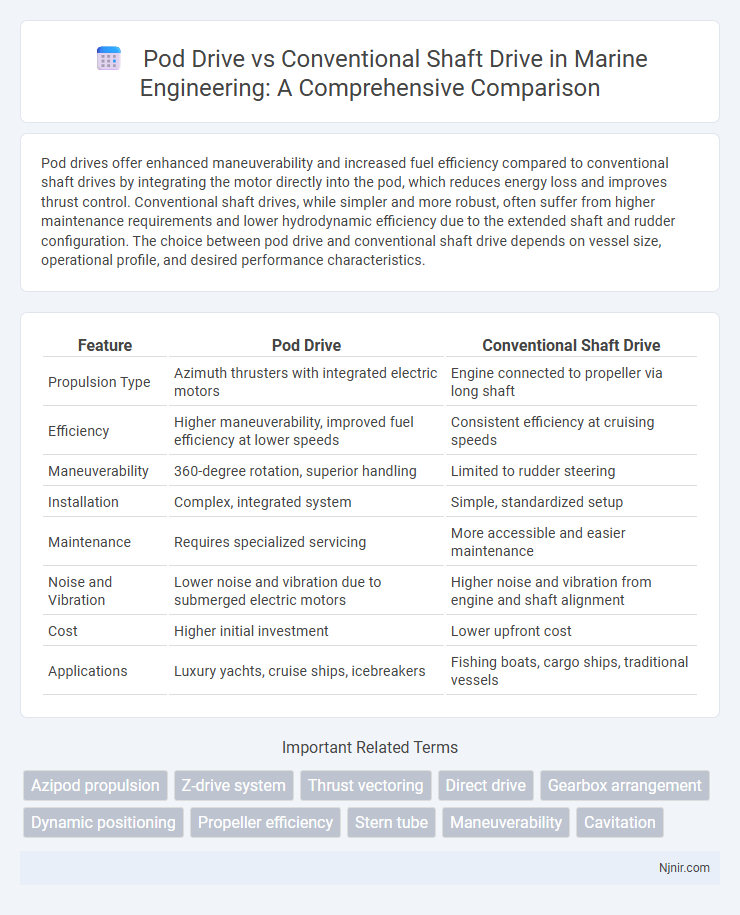

Table of Comparison

| Feature | Pod Drive | Conventional Shaft Drive |

|---|---|---|

| Propulsion Type | Azimuth thrusters with integrated electric motors | Engine connected to propeller via long shaft |

| Efficiency | Higher maneuverability, improved fuel efficiency at lower speeds | Consistent efficiency at cruising speeds |

| Maneuverability | 360-degree rotation, superior handling | Limited to rudder steering |

| Installation | Complex, integrated system | Simple, standardized setup |

| Maintenance | Requires specialized servicing | More accessible and easier maintenance |

| Noise and Vibration | Lower noise and vibration due to submerged electric motors | Higher noise and vibration from engine and shaft alignment |

| Cost | Higher initial investment | Lower upfront cost |

| Applications | Luxury yachts, cruise ships, icebreakers | Fishing boats, cargo ships, traditional vessels |

Introduction to Marine Propulsion Systems

Pod drives offer enhanced maneuverability and higher fuel efficiency compared to conventional shaft drives, utilizing integrated electric motors housed in underwater pods for direct thrust. Conventional shaft drives rely on long shafts connected to inboard engines, making the system simpler but less efficient in terms of hydrodynamics and space utilization. Marine propulsion systems increasingly favor pod drives due to their reduced vibration, lower noise levels, and improved vessel performance in various maritime applications.

Overview of Pod Drive Technology

Pod drive technology integrates the propulsion unit directly with the propeller, allowing for enhanced maneuverability, improved fuel efficiency, and reduced mechanical complexity compared to conventional shaft drives. These systems often feature electric or hybrid powertrains with steerable pods, enabling precise thrust vectoring and better handling in tight spaces. Conventional shaft drives rely on a fixed engine connected via a long driveshaft to the propeller, resulting in higher maintenance demands and typically lower hydrodynamic efficiency.

Understanding Conventional Shaft Drive Systems

Conventional shaft drive systems transmit power from the engine to the wheels through a long rotating shaft connected to a differential, which distributes torque evenly between the wheels. These systems are favored for their durability, low maintenance requirements, and smooth power delivery in a variety of vehicles, including motorcycles and rear-wheel-drive cars. However, they often involve heavier components and can produce more drivetrain loss compared to pod drives, affecting overall efficiency.

Key Differences Between Pod Drive and Shaft Drive

Pod drives offer improved maneuverability and efficiency by integrating the propulsion unit directly into the hull, reducing mechanical complexity compared to conventional shaft drives, which use a long shaft connecting the engine to an external propeller. Pod drives enhance fuel economy and allow for better vessel control due to their 360-degree rotation capability, whereas shaft drives typically have fixed propellers with limited steering flexibility. Maintenance requirements differ significantly, as pod drives require less shaft alignment and vibration damping but involve specialized servicing, while shaft drives have a more straightforward mechanical layout with accessible components.

Efficiency and Performance Comparison

Pod drives offer higher efficiency than conventional shaft drives by minimizing drivetrain losses through direct propulsion units integrated into the hull, resulting in improved thrust and reduced fuel consumption. Conventional shaft drives often experience greater energy loss due to mechanical complexity, such as longer shafts and multiple bearings, which can decrease overall performance. The compact design of pod drives enhances maneuverability and acceleration, providing superior responsiveness compared to traditional shaft-driven systems.

Maneuverability and Handling

Pod drives offer superior maneuverability compared to conventional shaft drives due to their 360-degree rotation capability, enabling precise and tight turns in confined spaces. Conventional shaft drives rely on fixed propellers and rudders, which limit steering responsiveness and make handling less intuitive, especially at low speeds. The pod drive's direct thrust vectoring significantly enhances handling, allowing for smoother docking and improved control in challenging conditions.

Maintenance and Service Considerations

Pod drives require less routine maintenance because their compact design integrates the propulsion and steering systems, reducing the number of moving parts exposed to wear. Conventional shaft drives involve more frequent inspections and servicing of components like the intermediate shaft, stuffing box, and cutlass bearing to prevent leaks and ensure smooth operation. Service accessibility can be more straightforward with pod drives due to modular construction, whereas shaft drives may need more time and effort during repairs because of their extended drivetrain layout.

Installation and Space Requirements

Pod drives require less installation space compared to conventional shaft drives since they are mounted externally on the hull, eliminating the need for long internal shafts and reducing hull modifications. Conventional shaft drives demand extensive internal alignment and support structures, increasing installation complexity and occupying valuable engine room space. The compact design of pod drives allows for more flexible vessel layouts and easier retrofitting in existing boats.

Cost Analysis: Pod Drive vs Conventional Shaft Drive

Pod drive systems generally have higher upfront costs compared to conventional shaft drives due to advanced engineering and integrated propulsion components. Maintenance expenses for pod drives can be lower over time, attributed to easier access and fewer mechanical parts, whereas conventional shaft drives often involve more labor-intensive upkeep and potential costly repairs. Evaluating total cost of ownership highlights that while conventional shaft drives offer lower initial investment, pod drives may provide better long-term value through operational efficiency and reduced maintenance frequency.

Choosing the Right Propulsion: Factors to Consider

Choosing the right propulsion system involves evaluating efficiency, maintenance needs, and vessel performance; pod drives offer enhanced maneuverability and fuel efficiency through integrated electric motors positioned outside the hull, reducing drag compared to conventional shaft drives. Conventional shaft drives, known for robustness and simpler mechanical design, often provide cost-effective solutions with easier access for repairs but may sacrifice some fuel economy and agility. Consider vessel size, operational profile, and long-term maintenance costs when deciding between the precise control of pod drives and the reliability of shaft drives.

Azipod propulsion

Azipod propulsion offers enhanced maneuverability, increased fuel efficiency, and reduced noise compared to conventional shaft drives by integrating electric motors directly into steerable pod units outside the ship's hull.

Z-drive system

The Z-drive system offers enhanced maneuverability and efficiency compared to conventional shaft drives by using a pod-mounted, 360-degree rotatable thruster that eliminates the need for rudders and provides direct thrust vectoring.

Thrust vectoring

Pod drives offer superior thrust vectoring capabilities compared to conventional shaft drives by enabling precise maneuverability through independent azimuth rotation of the propulsion units, enhancing vessel handling and efficiency.

Direct drive

Pod drives offer higher efficiency and improved maneuverability compared to conventional shaft drives by utilizing direct drive technology that eliminates transmission losses and reduces mechanical complexity.

Gearbox arrangement

Pod drives integrate the gearbox directly within the underwater unit for compact and efficient propulsion, while conventional shaft drives position the gearbox inside the engine room, transmitting power through a long shaft to the propeller.

Dynamic positioning

Pod drives offer superior dynamic positioning accuracy compared to conventional shaft drives due to their enhanced maneuverability and direct thrust vectoring capabilities.

Propeller efficiency

Pod drives enhance propeller efficiency by providing direct thrust alignment and reduced shaft losses compared to conventional shaft drives.

Stern tube

Pod drive systems eliminate the need for a traditional stern tube by integrating propulsion and steering mechanisms externally, while conventional shaft drives rely on a sealed stern tube to house the rotating propeller shaft and prevent water ingress.

Maneuverability

Pod drives offer superior maneuverability compared to conventional shaft drives by enabling 360-degree rotation and instant thrust direction changes.

Cavitation

Pod drives reduce cavitation by optimizing propeller placement and minimizing pressure fluctuations compared to conventional shaft drives.

pod drive vs conventional shaft drive Infographic

njnir.com

njnir.com