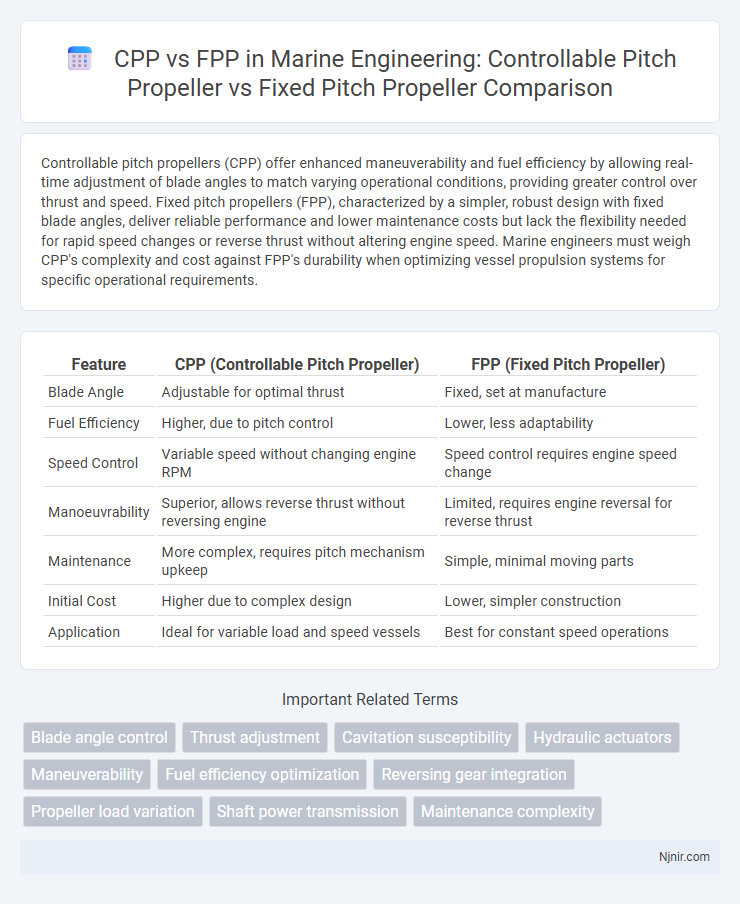

Controllable pitch propellers (CPP) offer enhanced maneuverability and fuel efficiency by allowing real-time adjustment of blade angles to match varying operational conditions, providing greater control over thrust and speed. Fixed pitch propellers (FPP), characterized by a simpler, robust design with fixed blade angles, deliver reliable performance and lower maintenance costs but lack the flexibility needed for rapid speed changes or reverse thrust without altering engine speed. Marine engineers must weigh CPP's complexity and cost against FPP's durability when optimizing vessel propulsion systems for specific operational requirements.

Table of Comparison

| Feature | CPP (Controllable Pitch Propeller) | FPP (Fixed Pitch Propeller) |

|---|---|---|

| Blade Angle | Adjustable for optimal thrust | Fixed, set at manufacture |

| Fuel Efficiency | Higher, due to pitch control | Lower, less adaptability |

| Speed Control | Variable speed without changing engine RPM | Speed control requires engine speed change |

| Manoeuvrability | Superior, allows reverse thrust without reversing engine | Limited, requires engine reversal for reverse thrust |

| Maintenance | More complex, requires pitch mechanism upkeep | Simple, minimal moving parts |

| Initial Cost | Higher due to complex design | Lower, simpler construction |

| Application | Ideal for variable load and speed vessels | Best for constant speed operations |

Introduction to Marine Propeller Systems

Marine propeller systems include Controllable Pitch Propellers (CPP) and Fixed Pitch Propellers (FPP), each serving distinct operational needs. CPPs feature adjustable blade angles, enabling precise thrust control and fuel efficiency under varying load conditions, making them ideal for maneuverability and variable speed requirements. FPPs have blades fixed at a single pitch, offering simplicity, durability, and cost-efficiency, often favored for vessels with steady operating speeds and consistent power demands.

Overview of Controllable Pitch Propellers (CPP)

Controllable Pitch Propellers (CPP) feature blades that can adjust their pitch angle to optimize thrust and fuel efficiency under varying operating conditions. This adaptability provides superior maneuverability, improved acceleration, and the ability to reverse thrust without changing the engine's rotation direction. CPP systems are commonly utilized in vessels requiring precise speed control and enhanced performance, such as tugboats, ferries, and offshore support ships.

Overview of Fixed Pitch Propellers (FPP)

Fixed Pitch Propellers (FPP) feature blades with a set angle that cannot be altered during operation, providing simplicity and cost-effectiveness in marine propulsion. They offer reliable and efficient performance for vessels with consistent speed and load requirements, minimizing mechanical complexity and maintenance needs. FPPs are widely used in commercial shipping and smaller boats due to their durability and straightforward design.

Design Differences: CPP vs FPP

Controllable Pitch Propellers (CPP) feature adjustable blade angles, allowing real-time optimization of thrust and efficiency across varying speeds and loads, enhancing maneuverability and fuel economy. Fixed Pitch Propellers (FPP) have blades set at a constant angle optimized for specific operating conditions, resulting in simpler design and lower maintenance but less flexibility. CPP systems incorporate complex hub mechanisms and hydraulic or electric controls to alter blade pitch, while FPP designs rely on fixed blades integrated directly into the propeller hub.

Operational Flexibility and Efficiency

Controllable Pitch Propellers (CPP) offer superior operational flexibility by allowing real-time blade angle adjustments, optimizing performance across variable speeds and load conditions. This adaptability enhances fuel efficiency and reduces engine stress compared to Fixed Pitch Propellers (FPP), which operate at a constant blade angle and are less responsive to changing marine or powerplant demands. CPP systems improve maneuverability and reduce vibration, resulting in smoother operation and potential maintenance savings over FPP configurations.

Maintenance and Lifecycle Costs

Controllable Pitch Propellers (CPP) typically incur higher maintenance costs due to their complex mechanical systems requiring regular inspection and adjustment of pitch control mechanisms. Fixed Pitch Propellers (FPP) have lower lifecycle costs because of their simpler design, resulting in fewer repair needs and reduced downtime. Over the vessel's operational lifespan, CPPs offer efficiency advantages that can offset maintenance expenses, but FPPs remain more cost-effective for minimal maintenance budgets.

Performance in Various Marine Applications

Controllable pitch propellers (CPP) offer superior performance across diverse marine applications by allowing real-time blade angle adjustments for optimal thrust and fuel efficiency, enhancing maneuverability in vessels such as tugs, ferries, and offshore supply ships. Fixed pitch propellers (FPP), characterized by a simpler, more robust design, provide high efficiency at a single, predetermined operating condition, often favored in cargo ships and bulk carriers running on consistent speed profiles. The adaptability of CPP systems results in improved acceleration, deceleration, and fuel economy in variable load and speed conditions, whereas FPPs deliver reliable, cost-effective propulsion in steady-state cruising scenarios.

Impact on Vessel Maneuverability

Controllable Pitch Propellers (CPP) significantly enhance vessel maneuverability by allowing real-time adjustment of blade angles, enabling precise control over thrust direction and magnitude without changing engine speed. This capability improves handling in tight spaces, reduces response time during acceleration and deceleration, and optimizes performance in varying sea conditions. In contrast, Fixed Pitch Propellers (FPP) offer limited maneuverability, relying solely on engine speed changes to adjust thrust, which can lead to slower response and less efficient handling during complex maneuvers.

Fuel Efficiency and Environmental Considerations

Controllable Pitch Propellers (CPP) offer enhanced fuel efficiency by allowing optimal blade angle adjustments that match varying engine loads and operating conditions, reducing fuel consumption compared to Fixed Pitch Propellers (FPP). CPP systems enable improved maneuverability and reduced emissions, contributing to lower environmental impact through decreased greenhouse gas output and better adaptation to eco-friendly operational profiles. Fixed Pitch Propellers, although simpler and more robust, often result in less precise fuel usage control, leading to higher fuel consumption and increased pollutant emissions over diverse voyage conditions.

Choosing Between CPP and FPP: Key Decision Factors

Choosing between a Controllable Pitch Propeller (CPP) and a Fixed Pitch Propeller (FPP) depends on vessel operational requirements and efficiency goals. CPP offers enhanced maneuverability and fuel efficiency by allowing real-time blade angle adjustments, making it ideal for variable speed operations and heavy load conditions. FPP provides simplicity and lower initial cost with high efficiency at constant speeds, suited for vessels with steady operating profiles and minimal need for rapid thrust changes.

Blade angle control

Controllable pitch propellers adjust blade angles dynamically to optimize thrust and fuel efficiency, while fixed pitch propellers have fixed blade angles, limiting performance adaptability.

Thrust adjustment

Controllable pitch propellers enable precise thrust adjustment by varying blade angles without changing shaft speed, whereas fixed pitch propellers require speed variation to alter thrust levels.

Cavitation susceptibility

Controllable pitch propellers (CPP) exhibit lower cavitation susceptibility than fixed pitch propellers (FPP) due to their ability to adjust blade angles dynamically, optimizing hydrodynamic performance and reducing pressure fluctuations that cause cavitation.

Hydraulic actuators

Hydraulic actuators in Controllable Pitch Propellers (CPP) enable precise blade angle adjustments for improved fuel efficiency and maneuverability compared to Fixed Pitch Propellers (FPP) with static blades.

Maneuverability

Controllable pitch propellers (CPP) enhance maneuverability by allowing precise blade angle adjustments for rapid thrust changes and improved low-speed control, unlike fixed pitch propellers (FPP) which have fixed blade angles limiting responsiveness.

Fuel efficiency optimization

Controllable pitch propellers (CPP) optimize fuel efficiency by adjusting blade angles to match varying operational loads, significantly reducing fuel consumption compared to fixed pitch propellers (FPP) with constant blade angles.

Reversing gear integration

Controllable pitch propellers enable seamless reversing gear integration by adjusting blade angles for efficient maneuvering, unlike fixed pitch propellers which require complex mechanical systems for reverse thrust.

Propeller load variation

Controllable pitch propellers (CPP) enable precise adjustment of blade angles to optimize thrust and efficiently manage propeller load variations under changing operational conditions, unlike fixed pitch propellers (FPP) which have a constant blade angle causing less flexibility and potentially higher load fluctuations.

Shaft power transmission

Controllable pitch propellers optimize shaft power transmission by adjusting blade angles for varying load conditions, enhancing efficiency compared to fixed pitch propellers with a constant blade angle.

Maintenance complexity

Maintenance complexity of controllable pitch propellers (CPP) is higher than fixed pitch propellers (FPP) due to their intricate blade adjustment mechanisms and hydraulic control systems requiring specialized skills and regular inspections.

CPP vs FPP (controllable pitch propeller vs fixed pitch propeller) Infographic

njnir.com

njnir.com