Thermal insulation in marine engineering primarily reduces heat transfer to maintain temperature stability within ship compartments, enhancing fuel efficiency and crew comfort. Acoustic insulation focuses on minimizing noise transmission from engines and machinery to create a quieter environment, improving onboard living conditions. Optimizing both types of insulation is crucial for efficient vessel operation and passenger well-being.

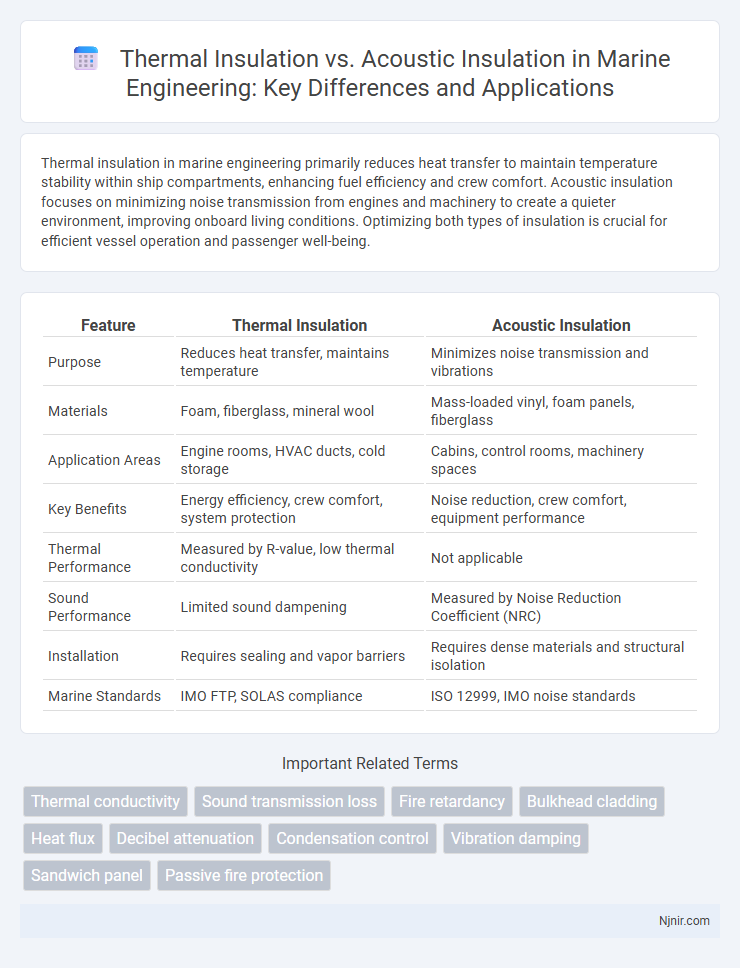

Table of Comparison

| Feature | Thermal Insulation | Acoustic Insulation |

|---|---|---|

| Purpose | Reduces heat transfer, maintains temperature | Minimizes noise transmission and vibrations |

| Materials | Foam, fiberglass, mineral wool | Mass-loaded vinyl, foam panels, fiberglass |

| Application Areas | Engine rooms, HVAC ducts, cold storage | Cabins, control rooms, machinery spaces |

| Key Benefits | Energy efficiency, crew comfort, system protection | Noise reduction, crew comfort, equipment performance |

| Thermal Performance | Measured by R-value, low thermal conductivity | Not applicable |

| Sound Performance | Limited sound dampening | Measured by Noise Reduction Coefficient (NRC) |

| Installation | Requires sealing and vapor barriers | Requires dense materials and structural isolation |

| Marine Standards | IMO FTP, SOLAS compliance | ISO 12999, IMO noise standards |

Introduction to Thermal and Acoustic Insulation in Marine Engineering

Thermal insulation in marine engineering primarily controls heat transfer to maintain temperature stability within ship compartments, crucial for energy efficiency and crew comfort. Acoustic insulation targets noise reduction from engines, machinery, and seawater impact, enhancing onboard living and working conditions. Both types of insulation rely on specialized materials like mineral wool and foam composites to meet marine environmental challenges.

Key Functions of Thermal Insulation on Ships

Thermal insulation on ships primarily functions to maintain stable internal temperatures by reducing heat transfer between the vessel's interior and the external marine environment, which enhances energy efficiency and protects onboard equipment. It also prevents condensation and corrosion, thereby extending the lifespan of structural components and machinery. Effective thermal insulation contributes to crew comfort by regulating cabin temperatures, ensuring safer and more productive working conditions at sea.

Primary Roles of Acoustic Insulation at Sea

Acoustic insulation at sea primarily reduces noise pollution from engines, machinery, and external maritime environments to protect crew health and enhance communication efficiency. Its role extends to minimizing sound transmission between compartments, ensuring operational safety and confidentiality on naval and commercial vessels. Unlike thermal insulation which regulates temperature, acoustic insulation focuses on sound absorption and vibration dampening critical for maintaining a quiet and functional onboard environment.

Material Differences: Thermal vs Acoustic Insulation

Thermal insulation materials such as fiberglass, mineral wool, and foam boards are primarily designed to reduce heat transfer by trapping air in tiny pockets, minimizing conduction and convection. Acoustic insulation materials, including dense fibers like cellulose, rock wool, and specialized acoustic foam, focus on absorbing sound waves and reducing noise transmission through vibration dampening and sound absorption. The key difference lies in material density and structure: thermal insulators prioritize low thermal conductivity, while acoustic insulators emphasize permeability and mass to disrupt sound wave propagation.

Installation Techniques for Marine Insulation Systems

Thermal insulation in marine systems typically utilizes spray foam or rigid foam boards applied directly to hulls and bulkheads for efficient heat resistance, while acoustic insulation often employs mineral wool or specialized acoustic blankets installed within cabin walls and engine rooms to dampen noise. Marine insulation installation techniques require precise sealing and layering to prevent moisture ingress and maintain structural integrity under harsh marine conditions. Proper installation enhances both insulation types' performance, ensuring optimal energy efficiency and soundproofing essential for vessel safety and comfort.

Performance Metrics: Comparing Thermal and Acoustic Solutions

Thermal insulation performance is typically measured by R-value, indicating resistance to heat flow, while acoustic insulation effectiveness is quantified by Sound Transmission Class (STC) and Noise Reduction Coefficient (NRC) ratings. High R-value materials like foam or fiberglass reduce heat transfer, optimizing energy efficiency, whereas materials with high STC ratings, such as dense mineral wool, effectively block airborne noise. Acoustic absorption, assessed by NRC, focuses on minimizing reverberations, a metric irrelevant to thermal insulation but critical for sound clarity in spaces.

Regulatory Standards for Insulation in Marine Vessels

Marine vessel insulation must comply with international regulatory standards such as SOLAS (Safety of Life at Sea) and IMO (International Maritime Organization) guidelines, which specify distinct requirements for thermal and acoustic insulation. Thermal insulation materials need to meet fire resistance and thermal conductivity criteria to ensure crew safety and energy efficiency, while acoustic insulation must adhere to noise reduction regulations to protect crew health and maintain operational communication. Compliance with standards like ISO 6947 for thermal insulation and ISO 15665 for noise control is critical for certification and vessel seaworthiness.

Energy Efficiency and Environmental Impact

Thermal insulation significantly reduces energy consumption by minimizing heat transfer, leading to lower heating and cooling costs and decreased greenhouse gas emissions. Acoustic insulation primarily improves sound quality but can contribute to energy efficiency when combined with thermal insulation materials that trap air and provide added resistance to heat flow. Selecting eco-friendly insulation materials such as recycled cellulose or sheep wool enhances environmental sustainability by reducing resource extraction and promoting biodegradability.

Cost Analysis: Thermal vs Acoustic Insulation on Ships

Thermal insulation on ships often involves materials such as polyurethane foam or mineral wool, which provide effective temperature control at a moderate cost, typically ranging from $2 to $6 per square foot depending on thickness and density. Acoustic insulation requires specialized materials like mass-loaded vinyl or fiberglass blankets, which tend to be more expensive, with costs averaging $5 to $15 per square foot, due to higher material complexity and installation labor. Considering long-term operational savings, thermal insulation can reduce energy expenses significantly, while acoustic insulation primarily enhances crew comfort and regulatory compliance, making the cost analysis highly dependent on the ship's specific requirements and operational priorities.

Best Practices for Selecting Marine Insulation

Selecting marine insulation requires balancing thermal and acoustic properties to enhance vessel comfort and efficiency. High-performance materials like closed-cell foams provide excellent thermal resistance, reducing heat transfer and energy consumption, while specialized acoustic insulation such as mineral wool or fiberglass effectively dampens noise and vibrations. Prioritize insulation systems with proven marine-grade certifications that ensure durability against moisture, salt, and temperature variations to maximize lifespan and performance on board.

Thermal conductivity

Thermal insulation materials with low thermal conductivity minimize heat transfer, whereas acoustic insulation prioritizes sound absorption and may not effectively reduce thermal conductivity.

Sound transmission loss

Thermal insulation primarily reduces heat transfer, while acoustic insulation enhances sound transmission loss by minimizing airborne and impact noise through specialized materials and construction techniques.

Fire retardancy

Thermal insulation materials often provide better fire retardancy compared to acoustic insulation due to their design for heat resistance and flame retardant properties.

Bulkhead cladding

Bulkhead cladding with high-density materials enhances thermal insulation by reducing heat transfer while dense, layered designs improve acoustic insulation by effectively dampening sound transmission.

Heat flux

Thermal insulation reduces heat flux by limiting heat transfer through conduction, convection, and radiation, while acoustic insulation primarily targets sound wave attenuation with minimal impact on heat flux.

Decibel attenuation

Thermal insulation primarily reduces heat transfer while acoustic insulation attenuates sound by decreasing decibel levels, with specialized materials achieving up to 60 decibels of noise reduction.

Condensation control

Thermal insulation effectively reduces condensation by maintaining surface temperatures above dew point, whereas acoustic insulation primarily targets sound absorption and has limited impact on condensation control.

Vibration damping

Thermal insulation primarily reduces heat transfer through materials, while acoustic insulation focuses on vibration damping to minimize sound transmission and structural noise.

Sandwich panel

Sandwich panels provide superior thermal insulation by trapping heat within their core layers, while their dense outer surfaces enhance acoustic insulation by reducing sound transmission.

Passive fire protection

Passive fire protection combines thermal insulation to prevent heat transfer and acoustic insulation materials engineered to resist fire while minimizing sound transmission.

thermal insulation vs acoustic insulation Infographic

njnir.com

njnir.com