Variable speed pumps in marine engineering offer significant energy savings by adjusting flow rates to match operational demands, unlike fixed speed pumps that operate at constant speeds regardless of load. This adaptability reduces wear and tear, enhances system efficiency, and lowers maintenance costs on vessels. Fixed speed pumps, while simpler and less expensive initially, often result in higher energy consumption and less precise control over fluid dynamics in marine systems.

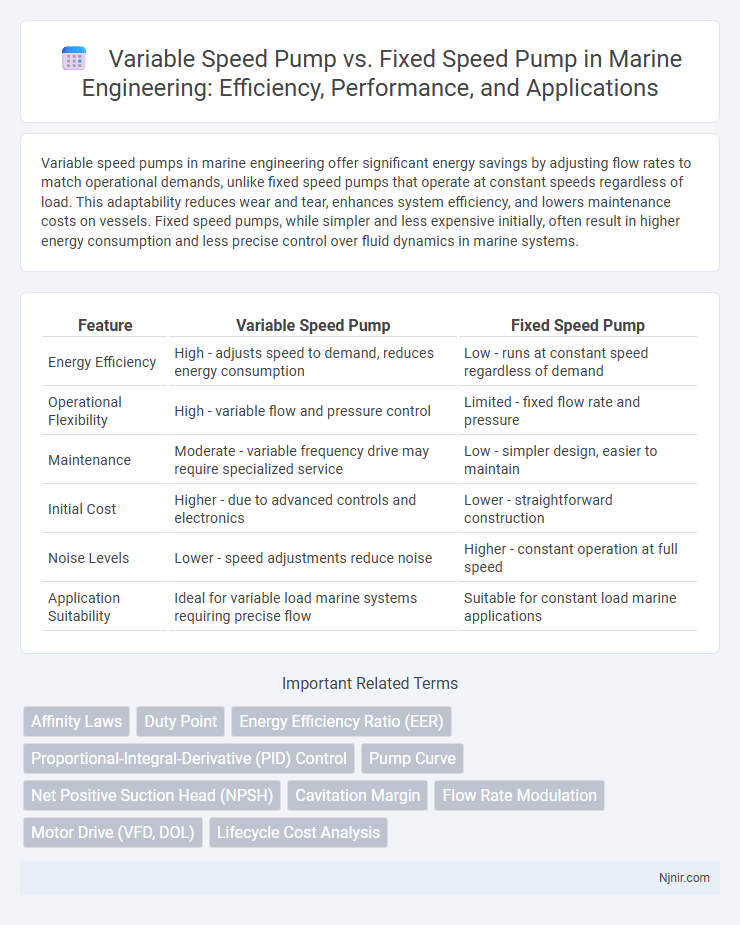

Table of Comparison

| Feature | Variable Speed Pump | Fixed Speed Pump |

|---|---|---|

| Energy Efficiency | High - adjusts speed to demand, reduces energy consumption | Low - runs at constant speed regardless of demand |

| Operational Flexibility | High - variable flow and pressure control | Limited - fixed flow rate and pressure |

| Maintenance | Moderate - variable frequency drive may require specialized service | Low - simpler design, easier to maintain |

| Initial Cost | Higher - due to advanced controls and electronics | Lower - straightforward construction |

| Noise Levels | Lower - speed adjustments reduce noise | Higher - constant operation at full speed |

| Application Suitability | Ideal for variable load marine systems requiring precise flow | Suitable for constant load marine applications |

Introduction to Pump Types in Marine Engineering

Variable speed pumps in marine engineering offer enhanced energy efficiency by adjusting flow rates to match system demands, reducing operational costs and wear. Fixed speed pumps operate at a constant rate, providing simplicity and reliability but often leading to energy waste during partial load conditions. Selecting between these pump types depends on vessel requirements, with variable speed pumps favored for dynamic applications and fixed speed pumps suited for consistent flow needs.

Overview of Variable Speed Pumps

Variable speed pumps adjust their motor speed based on system demand, resulting in significant energy savings and enhanced system efficiency compared to fixed speed pumps that run at constant speed. These pumps improve process control, reduce wear and tear, and lower operational costs by matching flow and pressure requirements precisely. Common applications include HVAC systems, water supply, and industrial processes where variable load conditions prevail.

Overview of Fixed Speed Pumps

Fixed speed pumps operate at a constant speed, delivering a fixed flow rate regardless of system demand, which can lead to energy inefficiencies and increased wear over time. These pumps are simpler in design, often resulting in lower initial costs and easier maintenance compared to variable speed pumps. Common in applications with stable flow requirements, fixed speed pumps are less adaptable to fluctuating operational conditions, limiting energy savings potential.

Energy Efficiency Comparison: Variable vs Fixed Speed Pumps

Variable speed pumps adjust motor speed to match system demand, significantly reducing energy consumption compared to fixed speed pumps that run continuously at full capacity. Energy savings from variable speed pumps can reach up to 50% in applications with fluctuating flow requirements, as they avoid throttling losses common in fixed speed systems. Optimizing pump operation through variable speed drives enhances overall system efficiency and lowers operational costs.

System Integration and Control Flexibility

Variable speed pumps offer superior system integration by adjusting flow rates and pressure dynamically to match real-time demand, reducing energy consumption and enhancing process control. Fixed speed pumps operate at constant flow and pressure, limiting flexibility and often requiring additional control devices to manage system variations. Advanced control systems paired with variable speed pumps enable precise modulation, improving overall system efficiency and reducing wear on equipment compared to fixed speed solutions.

Maintenance Requirements and Operational Lifespan

Variable speed pumps require less frequent maintenance due to their ability to adjust operating speeds, which reduces wear on components and energy consumption. Fixed speed pumps experience higher mechanical stress and energy inefficiency, leading to increased maintenance needs and shorter operational lifespan. Optimizing pump selection based on application can extend equipment life and lower overall maintenance costs.

Impact on Marine System Performance

Variable speed pumps enhance marine system performance by adjusting flow rates to match real-time demands, improving energy efficiency and reducing wear on components. Fixed speed pumps operate at constant flow regardless of system needs, leading to higher energy consumption and less precise control over pressure and fluid dynamics. The adaptability of variable speed pumps results in optimized propulsion and cooling processes, essential for maintaining system reliability and extending the lifespan of marine machinery.

Cost Analysis: Initial Investment and Operating Expenses

Variable speed pumps typically have a higher initial investment cost due to advanced control systems and technology integration compared to fixed speed pumps. Operating expenses are generally lower for variable speed pumps because they adjust motor speed to match demand, resulting in energy savings and reduced wear. Fixed speed pumps incur consistent energy consumption and maintenance costs, often making them less cost-effective over time despite lower upfront expenses.

Case Studies in Marine Applications

Case studies in marine applications demonstrate that variable speed pumps significantly enhance fuel efficiency and reduce operational costs compared to fixed speed pumps by adjusting flow rates to real-time demand. Vessels utilizing variable speed pumps reported up to 30% energy savings and improved system reliability under variable load conditions, leading to lower maintenance requirements. In contrast, fixed speed pumps often result in excess energy consumption and increased wear due to constant operation at full capacity regardless of demand fluctuations.

Future Trends in Marine Pump Technologies

Variable speed pumps enhance energy efficiency by adjusting flow rates to match real-time demand, reducing fuel consumption in marine vessels. Fixed speed pumps offer reliability with consistent operation but lack adaptability for changing load conditions, making them less suited for future sustainability goals. Emerging trends emphasize smart marine pump systems integrating IoT and AI for predictive maintenance and optimal performance, favoring variable speed technology to improve overall vessel efficiency and reduce environmental impact.

Affinity Laws

Variable speed pumps optimize energy efficiency by adjusting flow and head based on Affinity Laws, while fixed speed pumps operate at constant speed with less flexibility and higher energy consumption.

Duty Point

Variable speed pumps maintain optimal efficiency by adjusting flow to match the system's duty point, unlike fixed speed pumps which operate at a constant flow regardless of demand.

Energy Efficiency Ratio (EER)

Variable speed pumps typically achieve a higher Energy Efficiency Ratio (EER) than fixed speed pumps by adjusting motor speed to match load demand, reducing energy consumption and operational costs.

Proportional-Integral-Derivative (PID) Control

Variable speed pumps utilize Proportional-Integral-Derivative (PID) control to optimize energy efficiency and maintain precise flow rates, whereas fixed speed pumps operate at constant speed, lacking PID-based adaptability and efficiency.

Pump Curve

Variable speed pumps adjust flow and pressure along a flexible pump curve for energy efficiency, while fixed speed pumps operate at a constant point on a fixed pump curve, often resulting in energy waste under varying demand.

Net Positive Suction Head (NPSH)

Variable speed pumps optimize Net Positive Suction Head (NPSH) by adjusting flow rates to reduce cavitation risk, whereas fixed speed pumps maintain constant NPSH requirements, potentially increasing energy consumption and system wear.

Cavitation Margin

Variable speed pumps maintain a higher cavitation margin than fixed speed pumps by adjusting flow rates to avoid pressure drops that cause vapor bubble formation.

Flow Rate Modulation

Variable speed pumps provide precise flow rate modulation by adjusting motor speed to match demand, whereas fixed speed pumps operate at constant flow regardless of system requirements.

Motor Drive (VFD, DOL)

Variable speed pumps using Variable Frequency Drives (VFD) optimize energy efficiency and motor control compared to fixed speed pumps with Direct On Line (DOL) starters that operate at constant motor speed.

Lifecycle Cost Analysis

Lifecycle cost analysis reveals that variable speed pumps typically offer lower total ownership costs than fixed speed pumps due to energy savings, reduced maintenance, and extended equipment lifespan.

Variable speed pump vs Fixed speed pump Infographic

njnir.com

njnir.com