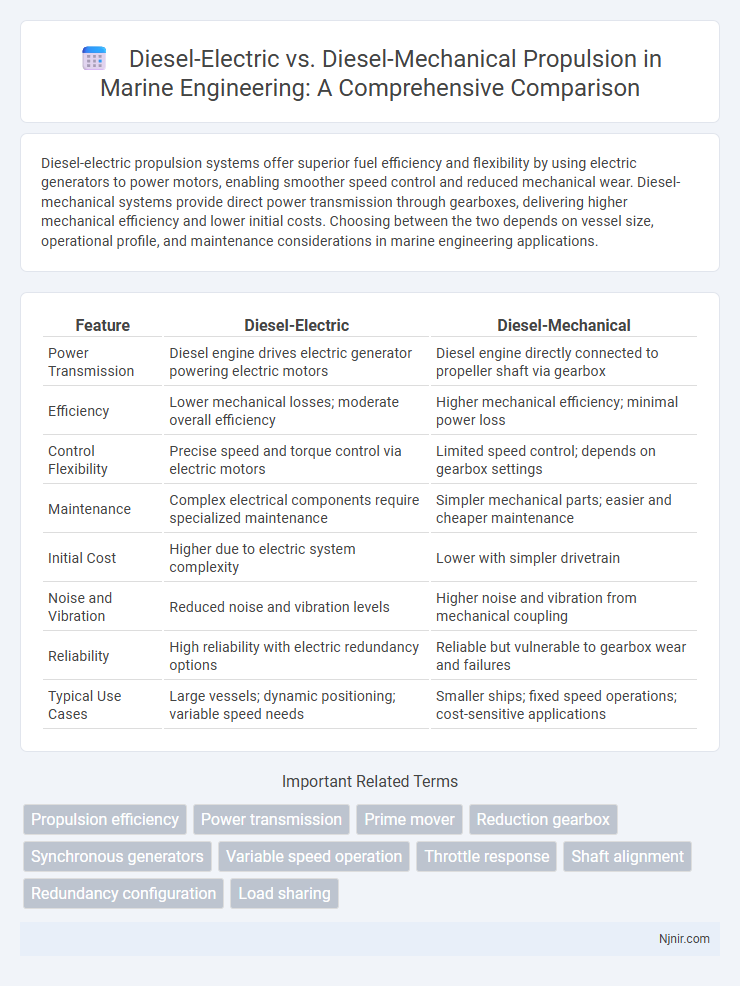

Diesel-electric propulsion systems offer superior fuel efficiency and flexibility by using electric generators to power motors, enabling smoother speed control and reduced mechanical wear. Diesel-mechanical systems provide direct power transmission through gearboxes, delivering higher mechanical efficiency and lower initial costs. Choosing between the two depends on vessel size, operational profile, and maintenance considerations in marine engineering applications.

Table of Comparison

| Feature | Diesel-Electric | Diesel-Mechanical |

|---|---|---|

| Power Transmission | Diesel engine drives electric generator powering electric motors | Diesel engine directly connected to propeller shaft via gearbox |

| Efficiency | Lower mechanical losses; moderate overall efficiency | Higher mechanical efficiency; minimal power loss |

| Control Flexibility | Precise speed and torque control via electric motors | Limited speed control; depends on gearbox settings |

| Maintenance | Complex electrical components require specialized maintenance | Simpler mechanical parts; easier and cheaper maintenance |

| Initial Cost | Higher due to electric system complexity | Lower with simpler drivetrain |

| Noise and Vibration | Reduced noise and vibration levels | Higher noise and vibration from mechanical coupling |

| Reliability | High reliability with electric redundancy options | Reliable but vulnerable to gearbox wear and failures |

| Typical Use Cases | Large vessels; dynamic positioning; variable speed needs | Smaller ships; fixed speed operations; cost-sensitive applications |

Introduction to Diesel-Electric and Diesel-Mechanical Propulsion

Diesel-electric propulsion systems use a diesel engine to drive an electric generator, which powers electric motors connected to the propeller shaft, offering precise speed control and improved fuel efficiency. Diesel-mechanical propulsion directly connects the diesel engine to the propeller through a gearbox, providing a simpler design with fewer energy conversion losses but less flexibility in speed regulation. This fundamental difference influences application choices, with diesel-electric favored for vessels requiring variable speeds and high maneuverability, while diesel-mechanical suits straightforward, steady-speed operations.

Fundamental Principles of Diesel-Electric Systems

Diesel-electric systems operate on the fundamental principle of converting mechanical energy from a diesel engine into electrical energy through a generator, which then powers electric traction motors driving the wheels. This configuration enables precise speed control and efficient power distribution, particularly advantageous in heavy machinery and locomotives. By contrast, diesel-mechanical systems transmit engine power directly to the wheels via a gearbox, limiting flexibility and efficiency in varying load conditions.

Core Concepts of Diesel-Mechanical Propulsion

Diesel-mechanical propulsion directly transfers engine power to the vehicle's drivetrain through a gearbox and clutch system, enabling efficient power delivery with minimal energy loss. This system is favored in applications requiring simple, robust mechanics and lower initial costs, such as small locomotives and agricultural machinery. Key components include the diesel engine, mechanical transmission, driveshaft, and final drive, emphasizing straightforward mechanical connection without electrical intermediaries.

Comparative Efficiency: Diesel-Electric vs Diesel-Mechanical

Diesel-electric systems convert mechanical energy from the diesel engine into electrical energy to power electric motors, providing higher efficiency across varying speeds and load conditions compared to diesel-mechanical systems. Diesel-mechanical transmissions directly connect the engine to the drivetrain, resulting in increased mechanical losses and reduced fuel efficiency, especially under fluctuating operational demands. Consequently, diesel-electric technology offers superior fuel economy and lower emissions due to its enhanced ability to optimize power delivery and engine performance.

Space and Weight Considerations in Marine Applications

Diesel-electric systems in marine applications optimize space by locating generators and electric motors separately, reducing engine room size and allowing flexible equipment placement, which is crucial on vessels with limited space. Diesel-mechanical systems require direct mechanical linkages between engines and propellers, resulting in heavier and bulkier configurations that limit space efficiency. The weight distribution in diesel-electric setups improves vessel stability and fuel efficiency, whereas diesel-mechanical layouts tend to concentrate mass, affecting balance and limiting design options.

Operational Flexibility and Maneuverability

Diesel-electric propulsion systems offer superior operational flexibility by enabling precise control over power output through electric motors, which enhances maneuverability in complex environments such as narrow harbors and industrial sites. Diesel-mechanical drives, while typically more efficient at steady speeds, lack the fine gradation of power adjustment and can be less responsive during frequent starts, stops, or speed changes. The ability of diesel-electric systems to seamlessly reverse thrust and provide multiple power vectoring options makes them preferable for applications requiring high agility and dynamic control.

Maintenance Requirements and Lifecycle Costs

Diesel-electric systems require regular maintenance of electrical components like generators and traction motors, which can increase short-term upkeep costs but often extend overall equipment lifespan due to reduced mechanical wear. Diesel-mechanical systems have simpler mechanical transmissions that are easier and cheaper to service but tend to experience higher wear and tear, leading to more frequent repairs and potentially shorter lifecycle. Lifecycle costs for diesel-electric setups are typically higher initially but lower long-term maintenance and fuel consumption can offset these expenses compared to diesel-mechanical alternatives.

Environmental Impact and Emissions

Diesel-electric systems produce lower emissions due to optimized engine operation and the ability to utilize electric power for variable loads, reducing fuel consumption and pollutants such as NOx and particulate matter. Diesel-mechanical transmissions often operate less efficiently under variable conditions, leading to higher fuel use and increased greenhouse gas emissions. Advances in diesel-electric technology further enhance environmental benefits by enabling easier integration with hybrid and renewable energy sources.

Suitability for Vessel Types and Missions

Diesel-electric propulsion excels in applications requiring variable speed control and high maneuverability, making it ideal for cruise ships, icebreakers, and research vessels. Diesel-mechanical systems are better suited for smaller vessels and those prioritizing straightforward, cost-effective propulsion, such as fishing boats and tugboats. The choice depends on mission profiles, with diesel-electric favored for complex, energy-intensive operations and diesel-mechanical for simpler, steady cruising tasks.

Future Trends in Marine Propulsion Technologies

Diesel-electric propulsion systems are gaining traction in marine applications due to their superior fuel efficiency, reduced emissions, and enhanced operational flexibility compared to traditional diesel-mechanical drives. The integration of advanced power management systems and energy storage solutions in diesel-electric configurations supports the shift toward hybrid and fully electric vessels, aligned with stricter international maritime regulations on greenhouse gas emissions. Future trends indicate increased adoption of diesel-electric technology coupled with renewable energy sources to optimize performance and sustainability in marine propulsion.

Propulsion efficiency

Diesel-electric propulsion offers higher efficiency in variable speed operations due to better torque control and reduced mechanical losses compared to diesel-mechanical systems.

Power transmission

Diesel-electric power transmission uses an electric generator and motors to transfer energy, providing smoother torque control and flexibility, while diesel-mechanical systems transmit power directly through a gearbox, offering higher mechanical efficiency but less adaptability in varying loads.

Prime mover

Diesel-electric prime movers convert diesel engine power to electrical energy driving electric motors, offering precise control and efficiency, while diesel-mechanical prime movers directly transfer mechanical power through gears, providing simplicity and higher mechanical efficiency in applications like locomotives and heavy machinery.

Reduction gearbox

Diesel-electric systems use electric motors to drive the propeller, eliminating the need for a reduction gearbox, whereas diesel-mechanical systems rely on a reduction gearbox to match engine speed with optimal propeller rotation.

Synchronous generators

Diesel-electric systems utilize synchronous generators for efficient power conversion and stable frequency output, whereas diesel-mechanical systems rely on direct mechanical coupling without synchronous generation.

Variable speed operation

Diesel-electric systems enable precise variable speed operation through electric traction motors, whereas diesel-mechanical systems have limited variable speed control due to direct mechanical linkages.

Throttle response

Diesel-electric systems offer faster and smoother throttle response compared to diesel-mechanical systems due to the immediate electrical power modulation without mechanical gear shifts.

Shaft alignment

Diesel-electric systems eliminate shaft alignment issues by using electric transmission between engine and propeller, whereas diesel-mechanical systems require precise shaft alignment to prevent vibrations and mechanical wear.

Redundancy configuration

Diesel-electric systems offer superior redundancy through independent electric drives and modular components, minimizing failure impact, whereas diesel-mechanical setups rely on a single mechanical transmission line, limiting redundancy options and increasing failure risk.

Load sharing

Diesel-electric systems enable superior load sharing through precise electronic control and power distribution, whereas diesel-mechanical systems rely on mechanical linkages that limit flexible load management.

Diesel-electric vs Diesel-mechanical Infographic

njnir.com

njnir.com