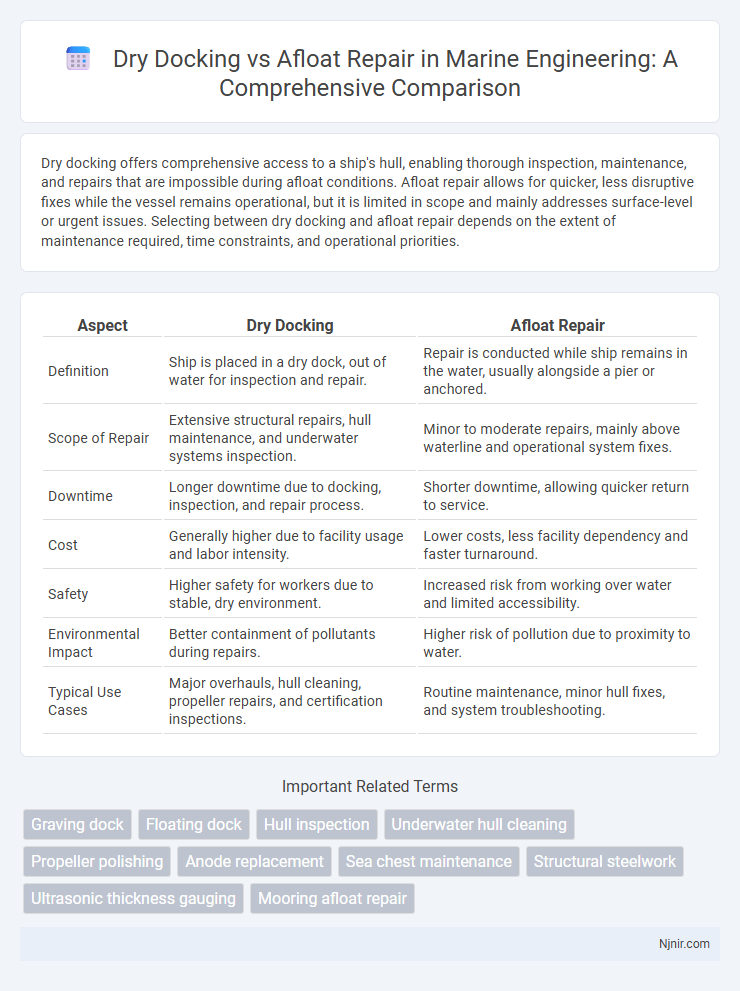

Dry docking offers comprehensive access to a ship's hull, enabling thorough inspection, maintenance, and repairs that are impossible during afloat conditions. Afloat repair allows for quicker, less disruptive fixes while the vessel remains operational, but it is limited in scope and mainly addresses surface-level or urgent issues. Selecting between dry docking and afloat repair depends on the extent of maintenance required, time constraints, and operational priorities.

Table of Comparison

| Aspect | Dry Docking | Afloat Repair |

|---|---|---|

| Definition | Ship is placed in a dry dock, out of water for inspection and repair. | Repair is conducted while ship remains in the water, usually alongside a pier or anchored. |

| Scope of Repair | Extensive structural repairs, hull maintenance, and underwater systems inspection. | Minor to moderate repairs, mainly above waterline and operational system fixes. |

| Downtime | Longer downtime due to docking, inspection, and repair process. | Shorter downtime, allowing quicker return to service. |

| Cost | Generally higher due to facility usage and labor intensity. | Lower costs, less facility dependency and faster turnaround. |

| Safety | Higher safety for workers due to stable, dry environment. | Increased risk from working over water and limited accessibility. |

| Environmental Impact | Better containment of pollutants during repairs. | Higher risk of pollution due to proximity to water. |

| Typical Use Cases | Major overhauls, hull cleaning, propeller repairs, and certification inspections. | Routine maintenance, minor hull fixes, and system troubleshooting. |

Understanding Dry Docking in Marine Engineering

Dry docking in marine engineering involves removing a vessel from water to access the hull for thorough inspection, maintenance, and repairs that cannot be performed afloat. This method allows for precise work on underwater components such as propellers, rudders, and hull plating, ensuring structural integrity and compliance with safety regulations. Dry docking is essential for preventing corrosion, biofouling, and extending the operational lifespan of ships by facilitating comprehensive overhauls and inspections.

Overview of Afloat Repair Techniques

Afloat repair techniques involve maintenance and minor repairs performed while the vessel remains in water, utilizing methods such as underwater welding, hull cleaning, and patching leaks with cofferdams or inflatable seals. These procedures minimize downtime by allowing essential repairs without dry docking, relying on specialized divers and remotely operated vehicles (ROVs) to access submerged areas. Key advantages include reduced operational disruptions and cost savings, although the scope of repair is typically limited compared to dry docking.

Key Differences Between Dry Docking and Afloat Repairs

Dry docking involves placing a vessel in a specialized dock to completely expose the hull for thorough inspection, maintenance, and repairs, while afloat repairs are performed on the vessel while it remains in the water, limiting access to submerged hull areas. Dry docking allows for extensive structural work, hull cleaning, painting, and propeller maintenance, whereas afloat repairs are typically suited for minor damage, routine servicing, and urgent fixes without interrupting vessel operations. The choice between dry docking and afloat repairs depends on repair scale, vessel availability, and operational requirements.

Advantages of Dry Docking for Vessel Maintenance

Dry docking offers comprehensive access to a vessel's hull, enabling thorough inspection, cleaning, and repairs that are impossible during afloat repair. This method ensures safer, high-quality maintenance, including structural work, coatings, and propulsion system servicing, resulting in extended vessel lifespan and improved operational efficiency. Dry docking also minimizes environmental risks and downtime by facilitating controlled conditions for hazardous waste handling and repair accuracy.

Benefits of Afloat Repair in Marine Operations

Afloat repair enables vessels to undergo maintenance and minor repairs without the need to enter a dry dock, significantly reducing downtime and operational costs. This method allows for flexibility in scheduling and minimizes disruptions to shipping schedules, supporting continuous marine operations. The ability to perform repairs in situ also reduces logistical challenges and enhances overall efficiency in maritime asset management.

Cost Comparison: Dry Docking vs Afloat Repair

Dry docking typically incurs higher direct costs due to the extensive infrastructure and time required to lift and secure a vessel out of water, but it allows for comprehensive inspections and repairs not feasible during afloat repair. Afloat repair generally offers lower immediate expenses, leveraging on-site equipment and minimizing downtime, making it cost-effective for minor maintenance or urgent fixes. The overall cost comparison depends on the scope of work, vessel size, and repair complexity, with dry docking favored for major overhauls and afloat repair suited for routine maintenance.

Situational Suitability: When to Choose Dry Docking

Dry docking is most suitable for extensive hull maintenance, structural repairs, or machinery overhaul that require complete vessel access and dewatering. It is preferred when precise underwater inspection or long-duration repairs are needed, ensuring safety and compliance with maritime regulations. Afloat repair is chosen for minor or urgent fixes that can be conducted while the vessel remains in water, minimizing downtime and operational disruption.

Limitations and Risks of Afloat Repairs

Afloat repairs present limitations such as restricted access to underwater hull sections and constrained working space, which can hinder comprehensive inspection and maintenance. These conditions increase risks including potential safety hazards for crew and workers, reduced repair quality, and susceptibility to environmental factors like weather and tide variations. The inability to perform extensive structural repairs afloat often necessitates subsequent dry docking, impacting operational schedules and costs.

Environmental Impact: Dry Docking vs Afloat Service

Dry docking involves draining a ship's hull for extensive inspection and repair, which typically requires controlled waste management and containment systems to prevent pollution of marine environments. Afloat repair allows maintenance tasks to be performed while the vessel remains in water, reducing the risk of dry dock-related environmental disturbances but potentially increasing the hazard of direct pollutant discharge. Both methods demand stringent environmental regulations to manage hazardous materials, with dry docking often providing safer containment and treatment options compared to afloat services.

Future Trends in Ship Maintenance and Repair Methods

Future trends in ship maintenance and repair emphasize advanced afloat repair technologies to minimize operational downtime and reduce costs compared to traditional dry docking. Enhanced robotic systems and automation enable more precise and efficient underwater inspections and repairs, supporting real-time condition monitoring through IoT sensors and AI analytics. The integration of sustainable materials and energy-efficient practices is driving innovation toward eco-friendly maintenance solutions, reshaping the future of maritime vessel upkeep.

Graving dock

Graving docks provide a stable, enclosed environment ideal for extensive dry docking repairs, enabling thorough hull inspections and maintenance that afloat repairs cannot achieve due to water interference and limited accessibility.

Floating dock

Floating docks provide a cost-effective and flexible alternative to dry docking by enabling ships to undergo maintenance and repairs while remaining afloat, minimizing downtime and avoiding the need for permanent dry dock facilities.

Hull inspection

Dry docking provides a comprehensive hull inspection by allowing full access to the vessel's underside, whereas afloat repair limits hull inspection to accessible areas above the waterline.

Underwater hull cleaning

Underwater hull cleaning during dry docking allows thorough inspection and maintenance in a controlled environment, while afloat repair offers cost-effective, quicker cleaning without removing the vessel from water but with limited access to the hull.

Propeller polishing

Propeller polishing during dry docking ensures thorough maintenance by removing corrosion and marine growth under ideal conditions, while afloat repair offers quicker, less comprehensive propeller cleaning without halting vessel operations.

Anode replacement

Dry docking enables comprehensive anode replacement by fully exposing the hull for precise inspection and installation, while afloat repair allows limited anode replacement with restricted access and increased operational complexity.

Sea chest maintenance

Dry docking enables comprehensive sea chest maintenance through complete hull access and isolation, while afloat repair allows limited inspection and minor sea chest cleaning without vessel removal from water.

Structural steelwork

Dry docking enables comprehensive structural steelwork repairs through complete vessel support and access, while afloat repair limits structural steelwork interventions due to restricted accessibility and stability.

Ultrasonic thickness gauging

Ultrasonic thickness gauging during dry docking provides more accurate measurements due to stable conditions and full access to submerged surfaces compared to afloat repair.

Mooring afloat repair

Mooring afloat repair enables vessel maintenance without dry docking by securely anchoring ships alongside a pier or barge, reducing downtime and operational costs.

dry docking vs afloat repair Infographic

njnir.com

njnir.com