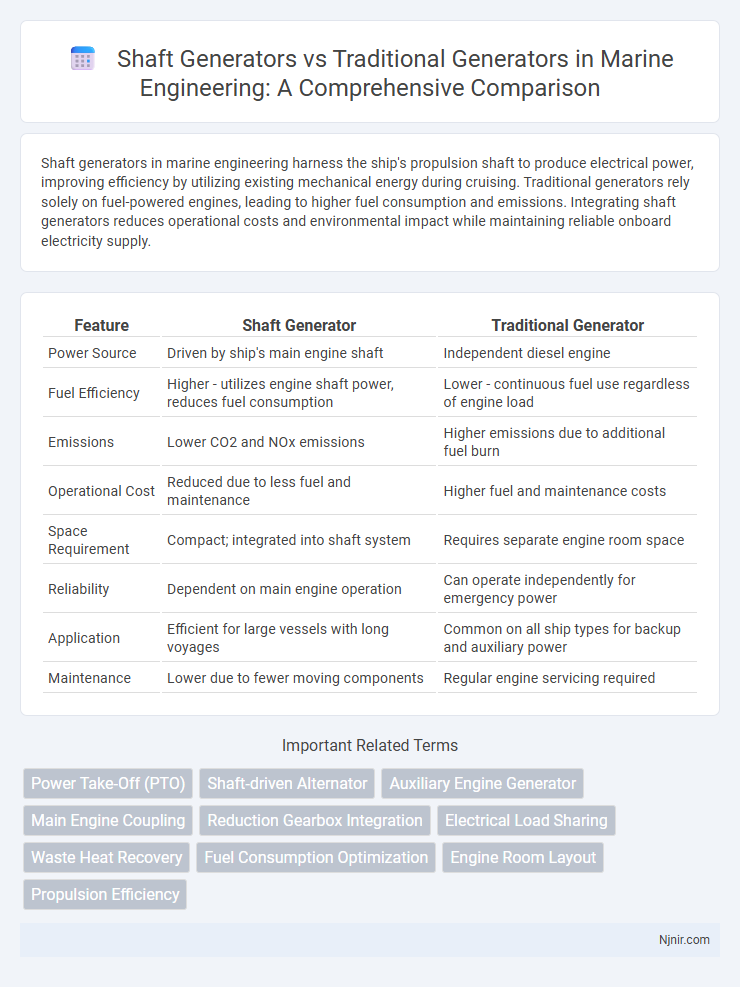

Shaft generators in marine engineering harness the ship's propulsion shaft to produce electrical power, improving efficiency by utilizing existing mechanical energy during cruising. Traditional generators rely solely on fuel-powered engines, leading to higher fuel consumption and emissions. Integrating shaft generators reduces operational costs and environmental impact while maintaining reliable onboard electricity supply.

Table of Comparison

| Feature | Shaft Generator | Traditional Generator |

|---|---|---|

| Power Source | Driven by ship's main engine shaft | Independent diesel engine |

| Fuel Efficiency | Higher - utilizes engine shaft power, reduces fuel consumption | Lower - continuous fuel use regardless of engine load |

| Emissions | Lower CO2 and NOx emissions | Higher emissions due to additional fuel burn |

| Operational Cost | Reduced due to less fuel and maintenance | Higher fuel and maintenance costs |

| Space Requirement | Compact; integrated into shaft system | Requires separate engine room space |

| Reliability | Dependent on main engine operation | Can operate independently for emergency power |

| Application | Efficient for large vessels with long voyages | Common on all ship types for backup and auxiliary power |

| Maintenance | Lower due to fewer moving components | Regular engine servicing required |

Introduction to Marine Power Generation

Shaft generators harness mechanical energy from a ship's main engine shaft to produce electrical power, improving fuel efficiency by reducing reliance on auxiliary diesel generators. Traditional generators on marine vessels operate independently using fuel-consuming engines, resulting in higher fuel consumption and emissions. Integrating shaft generators optimizes marine power generation, supporting more sustainable and cost-effective vessel operations.

Overview of Shaft Generators

Shaft generators convert mechanical energy from a ship's main engine shaft into electrical power, offering improved fuel efficiency by reducing the need for auxiliary engines. Traditional generators rely on separate engines to produce electricity, which increases fuel consumption and emissions. Shaft generators provide a seamless integration with the propulsion system, optimizing energy use on vessels.

Fundamentals of Traditional Marine Generators

Traditional marine generators operate by converting mechanical energy from the ship's engine or auxiliary power source into electrical energy using electromagnetic induction principles. These generators typically consist of a rotor, stator, and excitation system, producing consistent voltage and frequency to power onboard equipment. Unlike shaft generators, they run independently from the main propulsion shaft, requiring separate fuel consumption and maintenance schedules.

Energy Efficiency Comparison

Shaft generators, integrated with a ship's main engine, convert mechanical energy directly into electrical power, offering higher energy efficiency than traditional generators powered by separate auxiliary engines. Traditional generators typically consume additional fuel, resulting in increased operational costs and greater emissions. By utilizing the main engine's power, shaft generators reduce fuel consumption and improve overall energy efficiency in marine electrical systems.

Impact on Fuel Consumption

Shaft generators integrated with ship engines significantly reduce fuel consumption by harnessing mechanical energy directly from the main engine shaft, eliminating the need for separate auxiliary engines. Traditional generators rely solely on fuel-powered engines, increasing fuel usage and emissions, especially during low-load or standby operations. The efficiency of shaft generators can lead to fuel savings of up to 10-15%, contributing to lower operational costs and reduced environmental impact.

Space and Weight Considerations

Shaft generators integrated into a ship's propulsion system significantly reduce space and weight compared to traditional generators, as they utilize the main engine's rotational energy instead of requiring separate diesel engines. This consolidation minimizes the need for additional engine room space, lowering overall vessel weight and improving fuel efficiency. The compact design of shaft generators allows for enhanced cargo capacity and better weight distribution, benefiting ship stability and operational costs.

Maintenance and Reliability Factors

Shaft generators typically require less maintenance than traditional generators due to fewer moving parts and integrated design with the vessel's propulsion system. Reliability factors favor shaft generators as they provide continuous power generation when the main engine is operational, reducing dependency on auxiliary systems and minimizing fuel consumption. Traditional generators, while versatile and independent of engine operation, often face higher maintenance demands and potential downtime due to separate mechanical components and fuel systems.

Environmental and Emission Benefits

Shaft generators reduce environmental impact by utilizing the ship's main engine power to generate electricity, significantly lowering fuel consumption and emissions compared to traditional auxiliary generators. Traditional generators rely on separate diesel engines that emit higher levels of NOx, SOx, and CO2, contributing to greater air pollution and environmental harm. By optimizing fuel efficiency and minimizing greenhouse gas emissions, shaft generators support compliance with stringent maritime emission regulations and promote greener shipping operations.

Integration with Hybrid and Electric Propulsion

Shaft generators offer seamless integration with hybrid and electric propulsion systems by directly converting rotational energy from the main engine shaft into electrical power, enhancing energy efficiency and reducing fuel consumption. Unlike traditional generators that rely on separate engines, shaft generators minimize mechanical complexity and emissions by leveraging the vessel's existing propulsion machinery. This integration supports the transition to greener maritime technologies, enabling smoother power management and improved operational flexibility in hybrid and fully electric vessels.

Cost Analysis and Return on Investment

Shaft generators offer significant cost savings compared to traditional generators by reducing fuel consumption and minimizing maintenance expenses due to their integration with the ship's main engine. The initial investment in shaft generators is typically higher, but the improved fuel efficiency and lower operating costs result in a faster return on investment, often within a few years. Companies benefit from long-term financial gains by adopting shaft generators, as the reduction in fuel costs and extended equipment lifespan outweigh the upfront expenditure.

Power Take-Off (PTO)

Shaft generators integrate directly with the ship's main engine through a Power Take-Off (PTO) system, improving fuel efficiency and reducing emissions compared to traditional generators that operate independently using separate engines.

Shaft-driven Alternator

Shaft-driven alternators enhance energy efficiency by converting mechanical power from the engine shaft directly into electrical power, reducing fuel consumption and emissions compared to traditional belt-driven generators.

Auxiliary Engine Generator

Auxiliary engine generators provide reliable secondary power for ship operations, while shaft generators optimize fuel efficiency by converting propulsion shaft energy into electricity.

Main Engine Coupling

Shaft generators directly couple to the ship's main engine, providing efficient electrical power generation without the need for separate fuel consumption, unlike traditional generators that operate independently and rely on auxiliary engines.

Reduction Gearbox Integration

Shaft generators integrated with reduction gearboxes optimize energy efficiency and reduce mechanical losses compared to traditional generators by directly utilizing the propulsion shaft's rotational speed.

Electrical Load Sharing

Shaft generators enhance electrical load sharing by directly converting mechanical energy from the ship's engine into electrical power, reducing reliance on traditional generators and improving fuel efficiency.

Waste Heat Recovery

Shaft generators integrated with waste heat recovery systems improve overall energy efficiency by converting excess thermal energy into electrical power, unlike traditional generators that typically lack this capability.

Fuel Consumption Optimization

Shaft generators optimize fuel consumption by utilizing engine power during vessel operations, reducing reliance on auxiliary engines compared to traditional generators.

Engine Room Layout

Shaft generators integrate directly with the main engine in the engine room, reducing space and enhancing layout efficiency compared to traditional generators that require separate dedicated spaces and more complex wiring.

Propulsion Efficiency

Shaft generators enhance propulsion efficiency by directly converting mechanical energy from the ship's propulsion shaft into electrical power, reducing fuel consumption compared to traditional generators that rely solely on separate engine-driven systems.

shaft generator vs traditional generator Infographic

njnir.com

njnir.com