Planned Maintenance System (PMS) relies on scheduled inspections and routine tasks to prevent equipment failure in marine engineering, ensuring steady vessel operation through predefined intervals. Condition-Based Maintenance (CBM) utilizes real-time data and sensor technology to monitor equipment health, enabling maintenance only when specific indicators show signs of deterioration or failure. Integrating CBM within PMS enhances maintenance efficiency, reduces downtime, and optimizes resource allocation on ships.

Table of Comparison

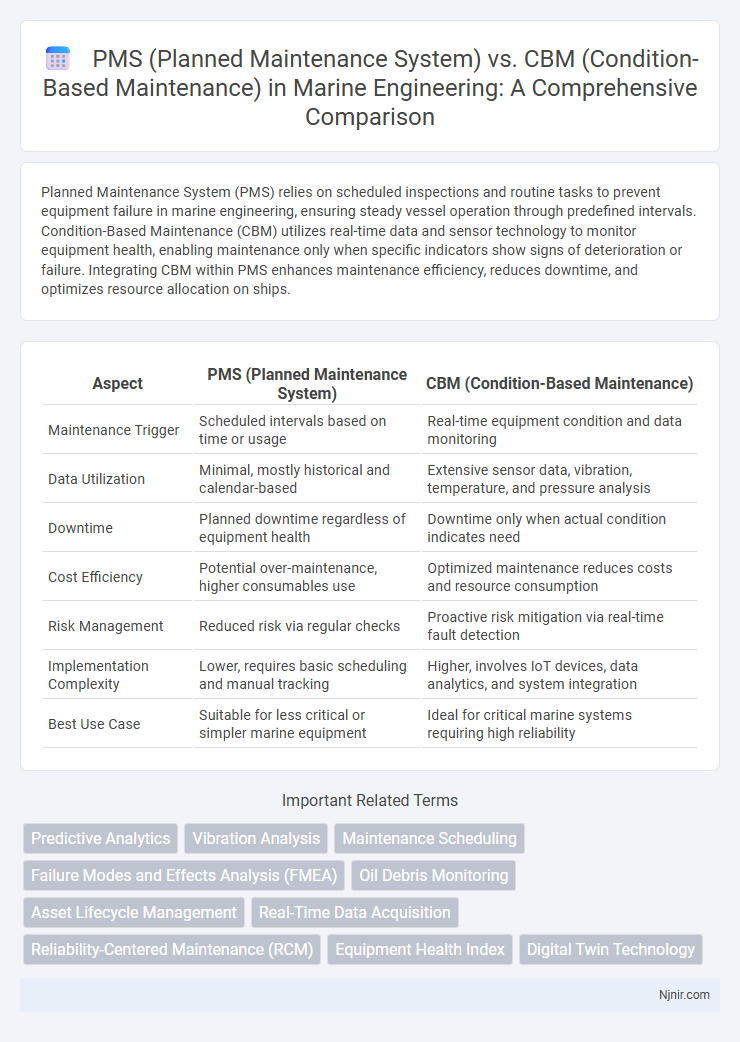

| Aspect | PMS (Planned Maintenance System) | CBM (Condition-Based Maintenance) |

|---|---|---|

| Maintenance Trigger | Scheduled intervals based on time or usage | Real-time equipment condition and data monitoring |

| Data Utilization | Minimal, mostly historical and calendar-based | Extensive sensor data, vibration, temperature, and pressure analysis |

| Downtime | Planned downtime regardless of equipment health | Downtime only when actual condition indicates need |

| Cost Efficiency | Potential over-maintenance, higher consumables use | Optimized maintenance reduces costs and resource consumption |

| Risk Management | Reduced risk via regular checks | Proactive risk mitigation via real-time fault detection |

| Implementation Complexity | Lower, requires basic scheduling and manual tracking | Higher, involves IoT devices, data analytics, and system integration |

| Best Use Case | Suitable for less critical or simpler marine equipment | Ideal for critical marine systems requiring high reliability |

Introduction to Marine Maintenance Strategies

Planned Maintenance System (PMS) in marine operations emphasizes scheduled inspections and servicing based on fixed time intervals or usage metrics to prevent equipment failure. Condition-Based Maintenance (CBM) relies on real-time data from sensors and diagnostic tools to assess equipment health, enabling maintenance actions only when certain conditions indicate potential degradation or failure. Integrating CBM with traditional PMS optimizes marine maintenance strategies by reducing downtime, lowering operational costs, and enhancing vessel reliability.

Overview of Planned Maintenance System (PMS)

Planned Maintenance System (PMS) involves scheduled inspections and servicing based on predefined time intervals or usage cycles to prevent equipment failures. PMS ensures consistent upkeep by following standardized checklists and maintenance protocols for machinery regardless of its current condition. This approach reduces unexpected breakdowns but may lead to unnecessary maintenance activities compared to condition-based strategies.

Fundamentals of Condition-Based Maintenance (CBM)

Condition-Based Maintenance (CBM) relies on real-time data and continuous monitoring of equipment conditions to predict maintenance needs, enhancing operational efficiency and reducing unplanned downtime. Unlike Planned Maintenance Systems (PMS) that follow fixed schedules regardless of equipment state, CBM uses sensors and diagnostic tools to assess parameters such as vibration, temperature, and wear. This proactive approach optimizes maintenance actions by addressing potential failures only when indicators show a decline in performance or risk, leading to cost savings and extended asset life.

Key Differences Between PMS and CBM

Planned Maintenance System (PMS) schedules maintenance activities at predetermined intervals regardless of equipment condition, ensuring consistent upkeep but potentially leading to unnecessary part replacements. Condition-Based Maintenance (CBM) relies on real-time monitoring and diagnostic data to perform maintenance only when specific indicators signal equipment degradation, optimizing resource use and minimizing downtime. Key differences include PMS's time-based approach versus CBM's data-driven triggers, impacting cost efficiency, equipment lifespan, and maintenance accuracy.

Advantages of Planned Maintenance in Marine Applications

Planned Maintenance Systems (PMS) in marine applications provide distinct advantages such as improved scheduling accuracy, ensuring maintenance activities align with vessel operations to minimize downtime and enhance safety. PMS allows for comprehensive documentation and regulatory compliance, critical for maritime standards and inspections. This proactive approach supports cost predictability by preventing unexpected failures and extending equipment lifespan through timely interventions.

Benefits of Implementing CBM on Ships

Implementing Condition-Based Maintenance (CBM) on ships enhances operational efficiency by enabling real-time monitoring of machinery health, which reduces unexpected breakdowns and downtime. CBM optimizes maintenance schedules based on actual equipment condition, leading to cost savings on unnecessary repairs compared to traditional Planned Maintenance Systems (PMS). This proactive approach extends the lifespan of critical ship components and improves overall vessel safety and reliability.

Challenges in Adopting PMS and CBM

Challenges in adopting Planned Maintenance Systems (PMS) include high initial setup costs, rigid scheduling that may lead to unnecessary maintenance, and difficulty in accurately predicting equipment failures. Condition-Based Maintenance (CBM) faces obstacles such as the need for sophisticated sensor technology, complex data analysis requirements, and the integration of real-time monitoring systems with existing operational workflows. Both PMS and CBM require specialized training and cultural shifts within organizations to ensure effective implementation and ongoing reliability improvements.

Cost Implications: PMS vs CBM in Marine Operations

Planned Maintenance System (PMS) often incurs higher upfront costs due to fixed schedules and routine part replacements irrespective of actual equipment condition, potentially leading to unnecessary maintenance expenses in marine operations. Condition-Based Maintenance (CBM) reduces overall maintenance costs by utilizing real-time data and predictive analytics to perform maintenance only when condition indicators signal deterioration or failure risk, optimizing resource allocation. Implementing CBM in marine environments can decrease downtime and extend asset life, offering significant cost savings compared to the more rigid and sometimes excessive maintenance cycles of PMS.

Technology and Tools for PMS and CBM

PMS (Planned Maintenance System) primarily relies on scheduled inspections and routine servicing using standard tools such as checklists, work orders, and CMMS (Computerized Maintenance Management Systems) to ensure timely asset upkeep. CBM (Condition-Based Maintenance) leverages advanced technologies like IoT sensors, vibration analysis, thermal imaging, and real-time data analytics platforms to monitor equipment health and predict failures. Integration of AI-driven diagnostic tools and cloud-based monitoring enhances CBM's precision, contrasting with PMS's time-based, manual approach.

Future Trends in Marine Maintenance Systems

Future trends in marine maintenance systems emphasize integrating AI-driven predictive analytics within PMS (Planned Maintenance Systems) to enhance schedule accuracy and reduce downtime. CBM (Condition-Based Maintenance) increasingly leverages IoT sensors and real-time data monitoring to optimize equipment life cycles by addressing issues before failures occur. Hybrid systems combining PMS and CBM methodologies demonstrate significant potential in advancing reliability, cost efficiency, and operational safety in maritime vessels.

Predictive Analytics

Predictive analytics enhances Condition-Based Maintenance (CBM) by utilizing real-time sensor data and machine learning algorithms for accurate failure prediction, whereas Planned Maintenance Systems (PMS) rely on fixed schedules without leveraging data-driven insights.

Vibration Analysis

Vibration analysis in condition-based maintenance (CBM) enables real-time detection of equipment faults, offering more precise and timely interventions compared to the fixed-interval inspections of planned maintenance systems (PMS).

Maintenance Scheduling

Planned Maintenance System (PMS) uses fixed schedules based on time or usage intervals, while Condition-Based Maintenance (CBM) optimizes maintenance scheduling by monitoring real-time equipment data to perform maintenance only when necessary.

Failure Modes and Effects Analysis (FMEA)

Condition-Based Maintenance (CBM) enhances Failure Modes and Effects Analysis (FMEA) by using real-time sensor data to detect equipment degradation, enabling targeted interventions compared to the time-based schedules of Planned Maintenance Systems (PMS).

Oil Debris Monitoring

Oil debris monitoring in condition-based maintenance (CBM) enables real-time detection of wear particles for proactive machinery health management, offering more precise fault diagnosis compared to the scheduled intervals of planned maintenance systems (PMS).

Asset Lifecycle Management

CBM enhances Asset Lifecycle Management by using real-time data to predict failures and schedule maintenance precisely, whereas PMS relies on fixed schedules that may lead to unnecessary downtime or unexpected asset failures.

Real-Time Data Acquisition

PMS relies on scheduled intervals for maintenance, whereas CBM leverages real-time data acquisition through sensors and IoT devices to optimize equipment performance and prevent unexpected failures.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) integrates Planned Maintenance Systems (PMS) and Condition-Based Maintenance (CBM) by prioritizing maintenance tasks based on equipment condition and reliability impact to maximize operational efficiency and reduce downtime.

Equipment Health Index

The Equipment Health Index in PMS relies on scheduled maintenance intervals, whereas in CBM it dynamically reflects real-time condition data to optimize maintenance timing.

Digital Twin Technology

Digital Twin Technology enhances CBM by providing real-time asset condition data for predictive insights, surpassing PMS's fixed schedule approach through dynamic, data-driven maintenance optimization.

PMS (planned maintenance system) vs CBM (condition-based maintenance) Infographic

njnir.com

njnir.com