Direct seawater cooling systems utilize seawater to absorb heat directly from marine engines, providing efficient temperature regulation with minimal infrastructure. Freshwater cooling systems circulate freshwater through the engine, using a heat exchanger to transfer heat to the seawater, which reduces corrosion and extends engine life. While direct seawater cooling offers simplicity and cost-effectiveness, freshwater cooling enhances equipment durability and minimizes maintenance in marine engineering applications.

Table of Comparison

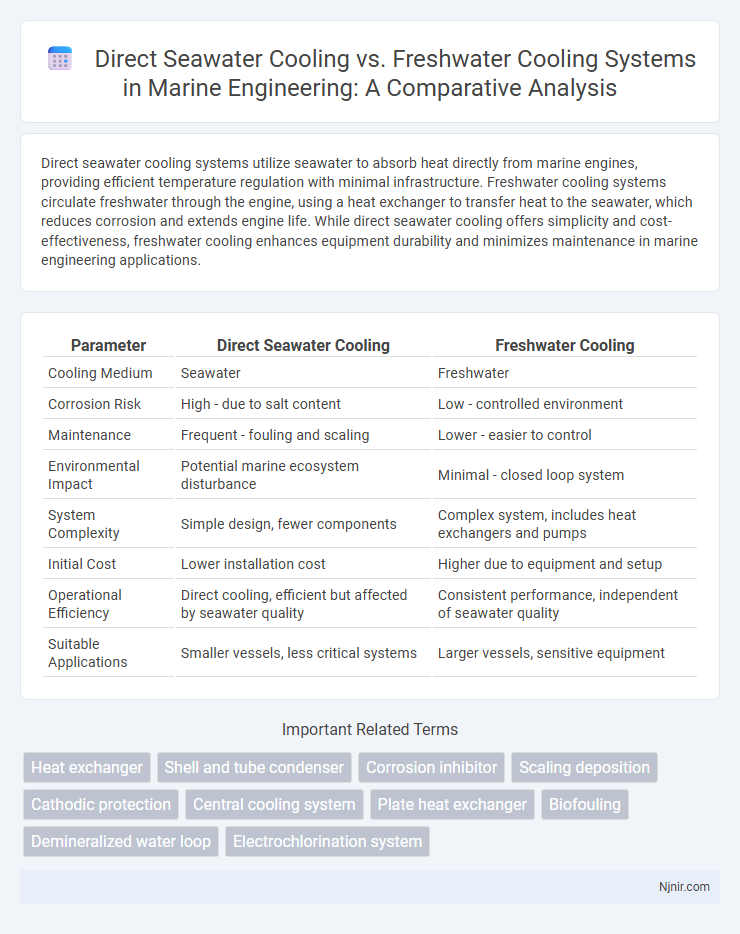

| Parameter | Direct Seawater Cooling | Freshwater Cooling |

|---|---|---|

| Cooling Medium | Seawater | Freshwater |

| Corrosion Risk | High - due to salt content | Low - controlled environment |

| Maintenance | Frequent - fouling and scaling | Lower - easier to control |

| Environmental Impact | Potential marine ecosystem disturbance | Minimal - closed loop system |

| System Complexity | Simple design, fewer components | Complex system, includes heat exchangers and pumps |

| Initial Cost | Lower installation cost | Higher due to equipment and setup |

| Operational Efficiency | Direct cooling, efficient but affected by seawater quality | Consistent performance, independent of seawater quality |

| Suitable Applications | Smaller vessels, less critical systems | Larger vessels, sensitive equipment |

Introduction to Marine Cooling Systems

Marine cooling systems utilize seawater or freshwater to regulate engine and equipment temperatures on vessels, ensuring optimal performance and preventing overheating. Direct seawater cooling systems draw ocean water directly through heat exchangers, offering simplicity and cost-effectiveness but requiring corrosion-resistant materials due to salt content. Freshwater cooling systems circulate treated freshwater within the engine, using seawater only in a separate heat exchanger, providing enhanced protection against corrosion and fouling while enabling better temperature control.

Overview of Direct Seawater Cooling

Direct seawater cooling systems utilize ocean water as a natural cooling medium, reducing the need for freshwater and chemical additives commonly used in traditional freshwater cooling. This approach minimizes environmental impact by eliminating thermal pollution and conserving limited freshwater resources. The system's efficiency hinges on corrosion-resistant materials and robust filtration to prevent marine biofouling and maintain optimal heat exchange performance.

Overview of Freshwater Cooling Systems

Freshwater cooling systems utilize treated water to absorb heat from machinery and industrial processes, providing efficient and controlled temperature regulation. These systems often include closed-loop circuits with heat exchangers to prevent contamination and reduce environmental impact. Compared to direct seawater cooling, freshwater systems offer enhanced corrosion resistance and easier maintenance but require continuous water treatment and energy for circulation.

Key Components and Design Differences

Direct seawater cooling systems utilize seawater as the primary heat transfer medium, incorporating corrosion-resistant heat exchangers, seawater pumps, and strainers to handle saline environments. Freshwater cooling systems rely on closed-loop circuits with freshwater as the coolant, featuring cooling towers, heat exchangers, pumps, and chemical treatment units to prevent scaling and biological growth. Design differences stem from material selection and system layout, with seawater systems emphasizing corrosion and fouling resistance, while freshwater systems prioritize thermal efficiency and water conservation through recirculation.

Efficiency and Heat Exchange Performance

Direct seawater cooling systems offer higher heat exchange efficiency due to the constant availability of cold seawater with stable temperatures, enhancing thermal transfer rates. Freshwater cooling systems often require additional heat exchangers and treatment processes, which can introduce efficiency losses and reduce overall heat transfer performance. The corrosive nature of seawater demands robust materials, but its superior cooling capacity typically results in more effective and energy-efficient heat exchange compared to freshwater systems.

Corrosion and Fouling Risks

Direct seawater cooling systems have higher corrosion risks due to constant exposure to saltwater, which accelerates metal degradation and requires corrosion-resistant materials like titanium or special coatings to mitigate damage. Fouling risks are significant in seawater systems as marine organisms such as barnacles and algae readily adhere to surfaces, necessitating frequent cleaning and antifouling treatments. Freshwater cooling systems typically face lower corrosion rates and fouling risks because of reduced salinity and fewer biological contaminants, contributing to longer equipment lifespan and lower maintenance costs.

Maintenance Requirements and Costs

Direct seawater cooling systems require rigorous maintenance due to corrosion and biofouling caused by saltwater exposure, often necessitating specialized treatments and more frequent inspections. Freshwater cooling systems generally incur lower maintenance costs as freshwater reduces risks of scaling and corrosion, allowing for longer equipment lifespan and less frequent cleaning. Overall, freshwater systems present reduced operational expenses, while seawater systems may demand higher initial investment in corrosion-resistant materials and ongoing maintenance to ensure efficiency.

Environmental Impact and Sustainability

Direct seawater cooling systems reduce freshwater consumption significantly by utilizing abundant ocean water, minimizing strain on inland water resources and promoting sustainable water management. However, such systems must carefully manage marine ecosystem disturbances caused by thermal discharge and potential entrainment of aquatic organisms to mitigate environmental impacts. Freshwater cooling systems typically consume large volumes of potable water and may generate more concentrated thermal pollution, making them less favorable in regions facing water scarcity and ecological vulnerability.

Suitability for Different Vessel Types

Direct seawater cooling systems are highly suitable for vessels operating in marine environments such as cargo ships, fishing boats, and offshore platforms due to their efficient heat exchange using abundant seawater. Freshwater cooling systems are preferred for luxury yachts, naval ships, and vessels with sensitive machinery, as they reduce corrosion risks and ensure cleaner cooling circuits through closed-loop operation. The choice depends on factors like vessel size, operational environment, and maintenance capabilities, with seawater cooling favored for robustness and freshwater systems preferred for durability and protection.

Comparative Analysis: Pros and Cons

Direct seawater cooling systems offer energy efficiency and reduced freshwater consumption by utilizing abundant seawater, but face challenges such as corrosion and biofouling risks requiring robust material protection and maintenance. Freshwater cooling systems minimize environmental impact on marine ecosystems and reduce salt-induced equipment degradation, yet demand significant freshwater resources and may involve higher operational costs for water treatment and replenishment. Selecting between these systems depends on site-specific factors like water availability, environmental regulations, and long-term maintenance capabilities.

Heat exchanger

Direct seawater cooling systems use corrosion-resistant heat exchangers to transfer heat efficiently while preventing seawater contamination, whereas freshwater cooling systems employ closed-loop heat exchangers with fresh water to minimize corrosion and biofouling risks.

Shell and tube condenser

Shell and tube condensers using direct seawater cooling offer enhanced corrosion resistance and reduced freshwater demand compared to freshwater cooling systems, optimizing thermal efficiency and operational longevity in marine applications.

Corrosion inhibitor

Direct seawater cooling systems require specialized corrosion inhibitors with high biofouling resistance due to saltwater's aggressive nature, whereas freshwater cooling systems use less intensive corrosion inhibitors suited for lower salinity environments.

Scaling deposition

Direct seawater cooling systems experience higher scaling deposition due to dissolved salts and minerals compared to freshwater cooling systems, which typically require less frequent maintenance to manage scale buildup.

Cathodic protection

Direct seawater cooling systems require more robust cathodic protection due to higher corrosion risks from saltwater exposure compared to freshwater cooling systems.

Central cooling system

Direct seawater cooling systems for central cooling reduce freshwater consumption by using seawater as a heat exchange medium, enhancing energy efficiency and lowering environmental impact compared to traditional freshwater cooling systems.

Plate heat exchanger

Plate heat exchangers in direct seawater cooling systems offer enhanced thermal efficiency and corrosion resistance compared to freshwater cooling systems, reducing maintenance costs and improving operational lifespan.

Biofouling

Direct seawater cooling systems face significantly higher biofouling risks due to continuous exposure to marine organisms compared to freshwater cooling systems, which experience lower biofouling rates and reduced maintenance costs.

Demineralized water loop

Direct seawater cooling systems reduce the risk of corrosion and scaling in the demineralized water loop by minimizing freshwater usage, enhancing thermal efficiency and lowering maintenance costs compared to freshwater cooling systems.

Electrochlorination system

Electrochlorination systems in direct seawater cooling use seawater's natural salinity to generate chlorine for biofouling control, offering lower chemical usage and operational costs compared to freshwater cooling systems that require external chlorination and extensive water treatment.

direct seawater cooling vs freshwater cooling system Infographic

njnir.com

njnir.com