Stern tube bearings support the propeller shaft inside the ship's hull, ensuring smooth rotation and preventing seawater ingress, while strut bearings are external supports that hold the shaft in alignment outside the hull, reducing shaft deflection and vibration. Stern tube bearings are typically lubricated by oil, providing a sealed environment, whereas strut bearings often use water lubrication and are designed to withstand hydrodynamic forces from surrounding water flow. The choice between stern tube and strut bearings impacts the vibration control, maintenance requirements, and overall efficiency of the propulsion system.

Table of Comparison

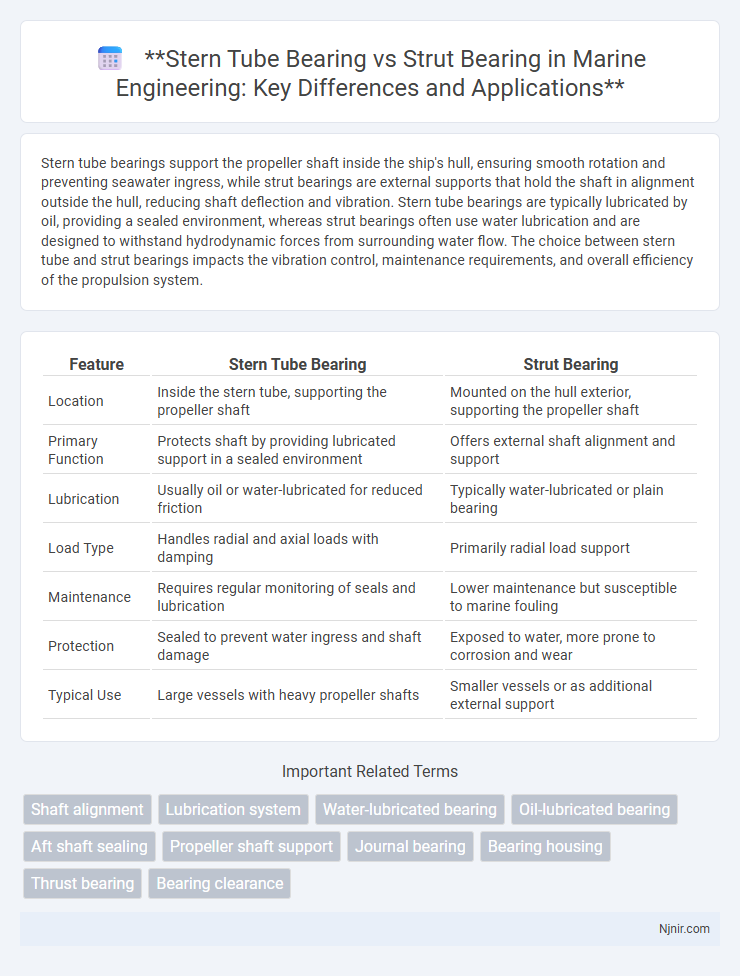

| Feature | Stern Tube Bearing | Strut Bearing |

|---|---|---|

| Location | Inside the stern tube, supporting the propeller shaft | Mounted on the hull exterior, supporting the propeller shaft |

| Primary Function | Protects shaft by providing lubricated support in a sealed environment | Offers external shaft alignment and support |

| Lubrication | Usually oil or water-lubricated for reduced friction | Typically water-lubricated or plain bearing |

| Load Type | Handles radial and axial loads with damping | Primarily radial load support |

| Maintenance | Requires regular monitoring of seals and lubrication | Lower maintenance but susceptible to marine fouling |

| Protection | Sealed to prevent water ingress and shaft damage | Exposed to water, more prone to corrosion and wear |

| Typical Use | Large vessels with heavy propeller shafts | Smaller vessels or as additional external support |

Introduction to Marine Shaft Bearings

Stern tube bearings and strut bearings are essential components in marine shafting systems, designed to support and align the propeller shaft while minimizing friction and wear. Stern tube bearings are typically located inside a sealed tube connected to the hull, using lubricating oil to reduce friction, whereas strut bearings are external supports mounted on the hull to stabilize the shaft outside the ship. Both types are crucial for maintaining efficient propulsion performance, reducing vibration, and ensuring the longevity of the marine propulsion shaft system.

Understanding Stern Tube Bearings

Stern tube bearings support the propeller shaft within the stern tube, ensuring smooth rotation and minimizing friction between the shaft and hull structure. These bearings are typically lubricated with oil or water to reduce wear and withstand harsh marine environments. Unlike strut bearings that support the shaft externally near the propeller, stern tube bearings provide continuous internal alignment and protection against seawater ingress.

Key Features of Strut Bearings

Strut bearings are designed to support the propeller shaft where it exits the hull, providing axial and radial load support while allowing smooth rotation. Key features of strut bearings include corrosion-resistant materials, water-lubricated surfaces for eco-friendly operation, and robust construction to withstand marine environments and reduce friction. Unlike stern tube bearings, which are sealed and lubricated with oil or grease, strut bearings often rely on seawater lubrication and are optimized for ease of maintenance and durability in harsh conditions.

Material Composition: Stern Tube vs Strut Bearings

Stern tube bearings are typically made from bronze alloys or specialized polymer composites designed to withstand seawater corrosion and provide excellent load-bearing capacity in marine environments. Strut bearings often use manganese-bronze or stainless steel combined with rubber or synthetic elastomer liners to enhance shock absorption and reduce vibration. The material composition of stern tube bearings prioritizes durability and corrosion resistance, while strut bearings focus on structural support and flexibility for dynamic hull movement.

Lubrication Methods and Maintenance

Stern tube bearings primarily use oil lubrication, often through a system that circulates filtered oil to reduce friction and wear, ensuring extended service life with minimal maintenance. Strut bearings typically rely on grease lubrication, which requires regular replenishment to prevent corrosion and ensure smooth operation in harsh marine environments. Effective maintenance of stern tube bearings involves monitoring oil quality and sealing integrity, while strut bearings need frequent inspection and regreasing to avoid mechanical failure and maintain vessel performance.

Installation Locations and Structural Roles

Stern tube bearings are installed within the ship's stern tube, supporting the propeller shaft and facilitating smooth rotation under water pressure conditions. Strut bearings are mounted externally on the ship's hull, providing lateral support to the propeller shaft and maintaining shaft alignment against hydrodynamic forces. These distinct installation locations reflect their structural roles, with stern tube bearings focusing on axial and radial load support inside the vessel, while strut bearings handle lateral loads and stabilize the shaft externally.

Performance Comparison: Efficiency and Durability

Stern tube bearings offer superior durability due to their robust lubrication systems and ability to handle high radial and axial loads, making them highly efficient in large vessel propulsion systems. Strut bearings, while simpler and lighter, often provide less efficiency under heavy operational stresses but excel in lower load applications with easier maintenance. The choice between stern tube and strut bearings hinges on balancing efficiency needs against durability requirements specific to ship design and operational conditions.

Common Failure Modes and Troubleshooting

Stern tube bearings often fail due to oil contamination, inadequate lubrication, and misalignment, leading to excessive wear and overheating. Strut bearing failures commonly arise from corrosion, cavitation damage, and improper installation, causing vibration and decreased structural integrity. Troubleshooting involves regular inspection for oil leaks, monitoring temperature and vibration levels, and ensuring correct alignment and sealing for both bearing types.

Applications in Different Vessel Types

Stern tube bearings are primarily used in larger vessels such as cargo ships and tankers where they support the propeller shaft, ensuring smooth rotation and minimizing friction in the stern tube. Strut bearings are commonly found on smaller vessels like fishing boats and passenger ferries, providing external support to the propeller shaft and maintaining alignment outside the hull. The choice between stern tube and strut bearings depends on vessel size, propulsion system design, and operating conditions, with stern tube bearings favored for heavy-duty applications and strut bearings for lighter, more exposed setups.

Selection Criteria: Choosing the Right Bearing

Selecting the right bearing for marine applications involves analyzing load capacity, lubrication requirements, and corrosion resistance. Stern tube bearings are preferred for supporting the propeller shaft with heavy axial and radial loads under seawater lubrication, while strut bearings are better suited for external shaft support with lower load demands and often use grease lubrication. Material compatibility and maintenance accessibility further influence the choice between stern tube and strut bearings to ensure durability and operational efficiency.

Shaft alignment

Stern tube bearings provide primary shaft alignment and support against radial loads in marine propulsion, while strut bearings maintain external shaft alignment and stability, primarily resisting lateral forces.

Lubrication system

Stern tube bearings typically utilize a sealed oil lubrication system to minimize water ingress and corrosion, while strut bearings often rely on water-lubricated or grease-lubricated systems designed for external, seawater-exposed conditions.

Water-lubricated bearing

Water-lubricated stern tube bearings provide superior corrosion resistance and lower environmental impact compared to water-lubricated strut bearings, which primarily support external shaft alignment and are exposed to varying hydrodynamic conditions.

Oil-lubricated bearing

Oil-lubricated stern tube bearings provide superior load distribution and reduced friction in ship propulsion systems compared to oil-lubricated strut bearings, which primarily support the propeller shaft externally.

Aft shaft sealing

Stern tube bearings provide robust aft shaft sealing by housing lubrication and sealing components in a pressure-tight chamber, whereas strut bearings primarily support the shaft externally without integrated sealing systems.

Propeller shaft support

Stern tube bearings provide sealed, lubricated support for propeller shafts within the stern tube, ensuring smooth rotation and protection from seawater, while strut bearings offer external support to the propeller shaft outside the hull, minimizing shaft deflection and vibration.

Journal bearing

Stern tube journal bearings provide continuous hydrodynamic lubrication to support the propeller shaft, offering superior load capacity and reduced friction compared to the structural support function of strut bearings.

Bearing housing

Stern tube bearing housings are designed to support rotating propeller shafts within a lubricated environment, featuring sealed compartments to prevent water ingress, while strut bearing housings are external, streamlined structures that support the propeller shaft outside the hull and typically use water-lubricated bearings without enclosed lubrication systems.

Thrust bearing

Stern tube bearings primarily support radial loads and reduce friction on the propeller shaft, while strut bearings incorporate thrust bearings to handle axial forces generated by propeller thrust effectively.

Bearing clearance

Stern tube bearings typically have a larger clearance of 0.1-0.3 mm to accommodate shaft alignment and thermal expansion, whereas strut bearings feature tighter clearance around 0.05-0.1 mm for precise shaft support and reduced vibration.

stern tube bearing vs strut bearing Infographic

njnir.com

njnir.com