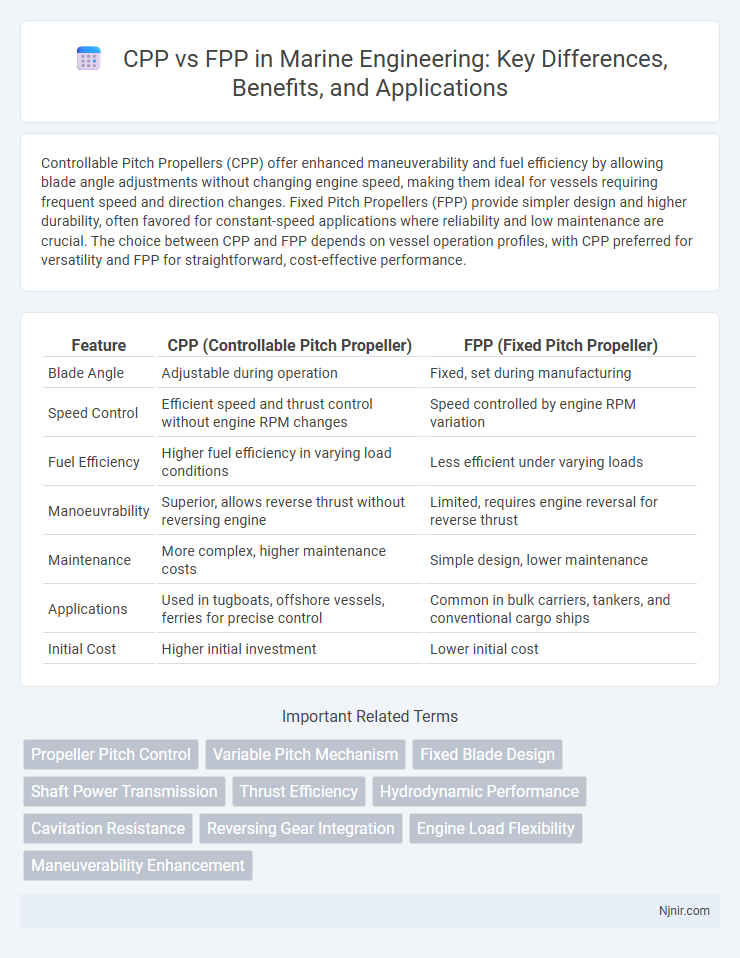

Controllable Pitch Propellers (CPP) offer enhanced maneuverability and fuel efficiency by allowing blade angle adjustments without changing engine speed, making them ideal for vessels requiring frequent speed and direction changes. Fixed Pitch Propellers (FPP) provide simpler design and higher durability, often favored for constant-speed applications where reliability and low maintenance are crucial. The choice between CPP and FPP depends on vessel operation profiles, with CPP preferred for versatility and FPP for straightforward, cost-effective performance.

Table of Comparison

| Feature | CPP (Controllable Pitch Propeller) | FPP (Fixed Pitch Propeller) |

|---|---|---|

| Blade Angle | Adjustable during operation | Fixed, set during manufacturing |

| Speed Control | Efficient speed and thrust control without engine RPM changes | Speed controlled by engine RPM variation |

| Fuel Efficiency | Higher fuel efficiency in varying load conditions | Less efficient under varying loads |

| Manoeuvrability | Superior, allows reverse thrust without reversing engine | Limited, requires engine reversal for reverse thrust |

| Maintenance | More complex, higher maintenance costs | Simple design, lower maintenance |

| Applications | Used in tugboats, offshore vessels, ferries for precise control | Common in bulk carriers, tankers, and conventional cargo ships |

| Initial Cost | Higher initial investment | Lower initial cost |

Introduction to CPP and FPP in Marine Engineering

In marine engineering, the comparison between Controllable Pitch Propellers (CPP) and Fixed Pitch Propellers (FPP) revolves around their operational flexibility and efficiency. CPP allows adjustment of blade angles during operation, optimizing thrust and fuel consumption across varying engine loads and speeds, which enhances maneuverability and performance in dynamic marine environments. FPP, characterized by fixed blade angles, offers simplicity and durability but operates at peak efficiency only within a narrow range of conditions, making it suitable for vessels with steady-speed requirements.

Operational Principles of Controllable Pitch Propellers (CPP)

Controllable Pitch Propellers (CPP) operate by adjusting the blade angle to optimize thrust and efficiency under varying load conditions, allowing for rapid changes in propulsion direction without altering engine speed. This adjustable pitch mechanism involves hydraulic or electric actuators linked to a central hub, providing precise control over blade pitch for maneuverability and fuel economy. Unlike Fixed Pitch Propellers (FPP), CPP systems enhance vessel operational flexibility by enabling optimal power transmission and improved response in dynamic marine environments.

Fixed Pitch Propellers (FPP): Design and Function

Fixed Pitch Propellers (FPP) feature blades set at a constant angle, optimizing efficiency for ships with stable operating speeds and engine RPMs. Their simple mechanical design, lacking adjustable components, reduces maintenance costs and enhances durability in marine propulsion systems. FPPs deliver consistent thrust by maintaining a fixed blade pitch, making them ideal for vessels with predictable power demands and straightforward maneuvering requirements.

Efficiency and Performance Comparison

First-Person Perspective (FPP) games offer more immersive gameplay by providing a direct view through the character's eyes, improving precision and reaction times crucial for fast-paced actions. Third-Person Perspective (TPP) or Third-Person Camera (TPC), often compared with FPP, enhances spatial awareness by giving a wider field of view, which can improve strategic movement and positioning efficiency. Performance differences between CPP (C++ programming perspective in gaming development) and FPP gameplay are not directly comparable; however, in terms of in-game efficiency, FPP optimizes player response times while TPP maximizes situational awareness, impacting overall game performance depending on play style and design goals.

Maneuverability and Vessel Control Differences

Counter-rotating Propeller (CPP) systems provide superior maneuverability compared to Fixed Pitch Propeller (FPP) setups due to the ability to change blade pitch, allowing for rapid thrust direction and magnitude adjustments without altering engine speed. CPP enhances vessel control during docking, slow-speed operations, and dynamic positioning, enabling more precise handling in confined waters. In contrast, FPP vessels rely on engine RPM changes for speed control, resulting in slower response times and reduced fine maneuverability.

Maintenance Requirements and Lifecycle Costs

CPP (Critical Point Protection) systems typically demand lower maintenance due to fewer moving parts and simpler operational protocols, reducing regular inspection frequency and repair costs. FPP (Fixed Point Protection) systems often incur higher lifecycle costs, driven by more complex components and frequent servicing requirements to ensure operational reliability over time. Choosing CPP can lead to long-term cost savings through decreased maintenance labor and extended equipment lifespan.

Energy Consumption and Fuel Economy

Constant Pressure Pilot (CPP) fuel systems typically exhibit higher energy consumption compared to Fixed Pressure Pilot (FPP) systems due to their continuous fuel flow regulation, which can lead to increased fuel usage. FPP systems maintain a consistent fuel pressure, optimizing fuel delivery and enhancing overall fuel economy by reducing wastage during engine operation. Studies show that vehicles equipped with FPP systems can achieve up to a 10-15% improvement in fuel efficiency over those using CPP configurations, making FPP preferable in applications prioritizing energy savings.

Application Suitability: Vessel Types and Uses

Closed Point Positioning (CPP) systems excel in dynamic vessel positioning for offshore supply vessels, drilling rigs, and complex construction ships due to their precise control and real-time adjustments. Fixed Point Positioning (FPP) is ideal for simpler vessel types like tugboats, fishing boats, and coastal ferries that operate in more predictable environments with fewer positional adjustments. Selecting CPP supports activities requiring high stability and accuracy in turbulent waters, while FPP suits applications focused on consistent routes and less demanding navigation tasks.

Environmental Impact and Regulatory Considerations

Cost Per Point (CPP) and Fixed Price Per Performance (FPP) models differ significantly in their environmental impact and regulatory considerations. CPP models may incentivize increased output, potentially leading to higher resource consumption and waste generation, raising environmental concerns subject to stricter regulatory scrutiny. FPP models promote efficiency and sustainability by aligning payment with performance metrics, often facilitating compliance with environmental regulations and reducing ecological footprints through optimized resource use.

Future Trends in Marine Propulsion Technology

Future trends in marine propulsion technology highlight a shift from conventional Central Power Plants (CPP) to advanced Full Power Plants (FPP) integrating hybrid and electric propulsion systems. Innovations in energy storage, such as high-capacity batteries and hydrogen fuel cells, enhance efficiency and reduce emissions in FPP configurations. Industry adoption of smart propulsion management combined with AI-driven optimization further accelerates the transition towards sustainable and environmentally-friendly marine propulsion solutions.

Propeller Pitch Control

Variable pitch systems in CPP (Controllable Pitch Propellers) enable precise Propeller Pitch Control for optimal thrust and fuel efficiency, unlike FPP (Fixed Pitch Propellers) which have a fixed blade angle limiting performance adaptability.

Variable Pitch Mechanism

The Variable Pitch Mechanism in Collective Pitch Propellers (CPP) allows dynamic blade angle adjustments for optimal thrust and fuel efficiency, contrasting with Fixed Pitch Propellers (FPP) that have a static blade angle limiting performance adaptability.

Fixed Blade Design

Fixed blade designs in CPP (Custom Precision Products) offer superior durability and strength compared to FPP (Folding Pocket Products), making them ideal for heavy-duty and tactical applications.

Shaft Power Transmission

CPP offers variable pitch control enhancing shaft power transmission efficiency, while FPP relies on fixed blade angles, limiting adaptability in changing load conditions.

Thrust Efficiency

CPP propellers offer variable pitch blades that optimize thrust efficiency across varying speeds, whereas FPP propellers have fixed blades resulting in lower thrust efficiency under changing operational conditions.

Hydrodynamic Performance

CPP propulsion systems optimize hydrodynamic performance by allowing variable blade pitch for enhanced efficiency across varying speeds, whereas FPP systems rely on fixed blade angles, resulting in less adaptability to changing hydrodynamic conditions.

Cavitation Resistance

CPP propellers typically exhibit higher cavitation resistance than FPP propellers due to their variable pitch blades allowing optimal angle adjustments under varying load conditions.

Reversing Gear Integration

Reversing gear integration in CPP systems offers precise thrust control and smoother directional changes compared to the fixed pitch propeller's reliance on separate reversing mechanisms.

Engine Load Flexibility

Continuous Pilot Power (CPP) offers superior engine load flexibility compared to Fixed Pilot Power (FPP) by enabling dynamic adjustment to varying operational demands, thereby improving fuel efficiency and reducing mechanical stress.

Maneuverability Enhancement

CPP propulsion systems enhance maneuverability by allowing precise thrust direction and variable speed control, whereas FPP systems offer less flexibility due to fixed blade pitch and speed limitations.

CPP vs FPP Infographic

njnir.com

njnir.com