Wireless monitoring in marine engineering offers enhanced flexibility and real-time data transmission, eliminating the need for complex cabling in harsh maritime environments. It reduces installation costs and maintenance challenges commonly associated with wired sensor systems, while enabling remote access to critical vessel performance metrics. Reliability and signal integrity remain key considerations, especially in electromagnetic interference-prone settings aboard ships.

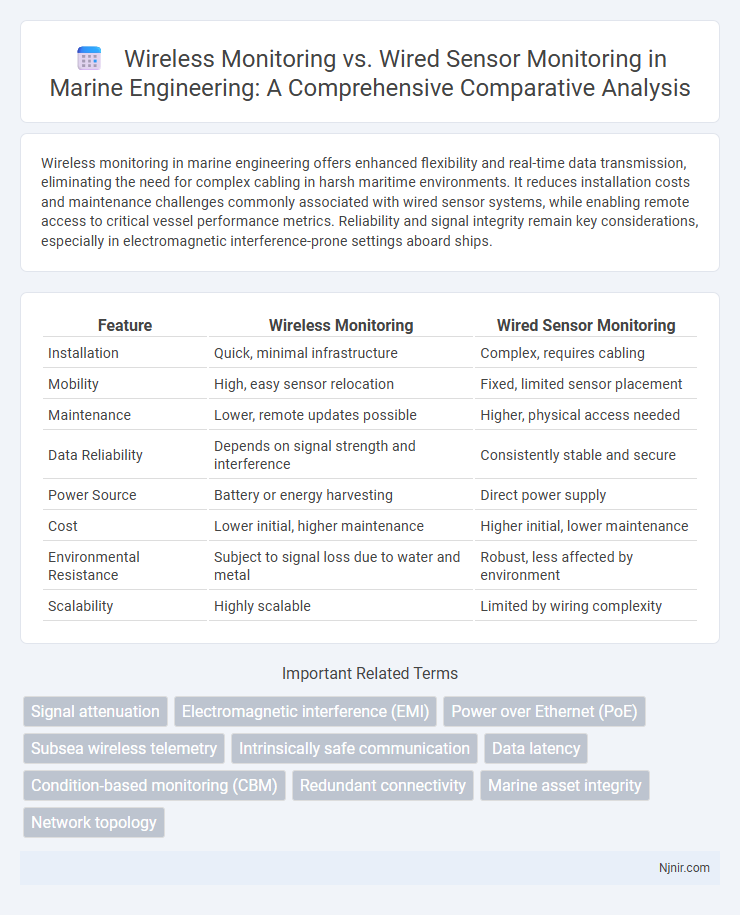

Table of Comparison

| Feature | Wireless Monitoring | Wired Sensor Monitoring |

|---|---|---|

| Installation | Quick, minimal infrastructure | Complex, requires cabling |

| Mobility | High, easy sensor relocation | Fixed, limited sensor placement |

| Maintenance | Lower, remote updates possible | Higher, physical access needed |

| Data Reliability | Depends on signal strength and interference | Consistently stable and secure |

| Power Source | Battery or energy harvesting | Direct power supply |

| Cost | Lower initial, higher maintenance | Higher initial, lower maintenance |

| Environmental Resistance | Subject to signal loss due to water and metal | Robust, less affected by environment |

| Scalability | Highly scalable | Limited by wiring complexity |

Introduction to Sensor Monitoring in Marine Engineering

Wireless monitoring systems in marine engineering offer enhanced flexibility and ease of installation compared to traditional wired sensor monitoring, enabling real-time data acquisition without extensive cabling. Wired sensor monitoring provides higher reliability and stable data transmission crucial for critical systems onboard ships. The integration of both technologies improves overall operational efficiency and safety by combining wireless adaptability with wired system robustness.

Overview of Wired Sensor Monitoring Systems

Wired sensor monitoring systems utilize physical cables to connect sensors directly to data acquisition devices, ensuring stable and reliable signal transmission with minimal interference. These systems are commonly employed in industrial environments where continuous, high-precision data collection is critical for process control and safety monitoring. Their structured cabling provides consistent power supply and secure data communication, albeit with less flexibility and higher installation costs compared to wireless alternatives.

Wireless Monitoring Technology: Fundamentals and Applications

Wireless monitoring technology enables remote data collection and real-time analysis without the constraints of physical wiring, significantly enhancing flexibility and scalability in sensor deployment. Utilizing radio frequency (RF) communication protocols such as Zigbee, LoRa, and Bluetooth Low Energy (BLE), wireless monitoring systems support seamless integration across diverse environments including industrial automation, environmental monitoring, and smart buildings. Advanced energy-efficient designs and robust encryption methods ensure reliable data transmission and extended sensor lifespan, making wireless monitoring an essential solution for dynamic and large-scale applications.

Installation and Maintenance: Wired vs Wireless Systems

Wired sensor monitoring systems require extensive cabling, making installation labor-intensive and costly, especially in large or complex environments. Wireless monitoring systems offer simplified installation with minimal infrastructure, enabling quick deployment and flexibility in sensor placement. Maintenance for wired systems often involves troubleshooting physical connections, while wireless systems require regular battery replacements and ensuring signal integrity.

Data Accuracy and Reliability in Marine Environments

Wireless monitoring systems in marine environments offer enhanced flexibility but may face challenges in maintaining consistent data accuracy due to signal interference and environmental factors like saltwater corrosion. Wired sensor monitoring provides superior reliability and stable data transmission by directly connecting sensors, minimizing data loss or corruption caused by external interferences. Optimal marine monitoring often involves hybrid solutions combining wired sensors' accuracy with wireless systems' adaptability to ensure comprehensive and reliable data collection.

Integration with Existing Marine Vessel Systems

Wireless monitoring systems offer seamless integration with existing marine vessel systems through wireless protocols like Wi-Fi and Bluetooth, reducing the need for extensive cabling and enabling real-time data transmission to onboard control units. Wired sensor monitoring relies on physical connections such as Ethernet or RS-485, ensuring stable and interference-resistant data transfer but requiring more complex installation and maintenance within the vessel's infrastructure. Both systems can interface with vessel management software, but wireless solutions provide greater flexibility for retrofitting older ships while wired systems favor new builds prioritizing reliability and continuous power supply.

Cost Comparison: Upfront and Lifecycle Expenses

Wireless monitoring systems typically incur lower upfront costs due to reduced installation expenses, as they eliminate the need for extensive cabling and trenching. However, wired sensor monitoring often presents lower long-term maintenance costs and greater reliability, which can result in more predictable lifecycle expenses. Evaluating total cost of ownership requires analyzing initial investment against ongoing operational and repair costs specific to the application environment.

Security and Data Protection Considerations

Wireless monitoring systems offer enhanced flexibility but face increased cybersecurity risks such as signal interception, hacking, and unauthorized access, requiring robust encryption protocols like AES-256 and regular firmware updates to safeguard data integrity. Wired sensor monitoring provides enhanced physical security through direct connections, minimizing exposure to wireless threats, but remains vulnerable to physical tampering and requires secure installation practices to prevent data breaches. Implementing multi-layered security strategies including end-to-end encryption, secure authentication, and network segmentation is critical for both wireless and wired systems to ensure comprehensive data protection.

Scalability and Flexibility for Future Upgrades

Wireless monitoring systems offer superior scalability by enabling easy addition or relocation of sensors without extensive cabling modifications, supporting dynamic expansion in large or evolving environments. Wired sensor monitoring provides stable performance but requires significant infrastructure changes to upgrade or scale, limiting flexibility in rapidly changing settings. Future upgrades favor wireless solutions due to their adaptability and reduced installation complexity, ensuring seamless integration of new technologies and sensor types.

Case Studies: Real-world Marine Applications and Outcomes

Case studies in marine applications reveal wireless monitoring systems offer enhanced flexibility and rapid deployment compared to traditional wired sensor monitoring, enabling real-time data acquisition in challenging offshore environments. For instance, wireless solutions have improved vessel condition monitoring by reducing installation time and maintenance costs, while maintaining data accuracy in corrosion detection and structural health assessments. Conversely, wired sensor monitoring continues to provide reliable, high-fidelity data for long-term subsea pipeline integrity monitoring, demonstrating a balance between robustness and operational efficiency.

Signal attenuation

Wireless monitoring experiences higher signal attenuation due to environmental interference compared to wired sensor monitoring, which provides more stable and consistent signal transmission.

Electromagnetic interference (EMI)

Wireless monitoring systems are more susceptible to electromagnetic interference (EMI) compared to wired sensor monitoring, which benefits from shielded cables that reduce EMI impact and ensure more reliable data transmission.

Power over Ethernet (PoE)

Power over Ethernet (PoE) enables wired sensor monitoring with reliable power and data transmission over a single cable, contrasting with wireless monitoring that offers greater installation flexibility but depends on battery life and wireless connectivity stability.

Subsea wireless telemetry

Subsea wireless telemetry offers enhanced flexibility and reduced installation costs compared to traditional wired sensor monitoring, enabling real-time data transmission in challenging underwater environments.

Intrinsically safe communication

Wireless monitoring enables intrinsically safe communication by eliminating electrical wiring that can spark in hazardous environments, unlike wired sensor monitoring which requires stringent explosion-proof barriers.

Data latency

Wireless monitoring typically experiences higher data latency compared to wired sensor monitoring due to signal transmission delays and interference.

Condition-based monitoring (CBM)

Wireless monitoring enhances condition-based monitoring (CBM) by providing real-time, flexible data acquisition and reduced installation costs compared to traditional wired sensor monitoring systems.

Redundant connectivity

Wireless monitoring systems offer enhanced redundant connectivity through multiple network paths and automatic failover compared to the limited redundancy options in wired sensor monitoring.

Marine asset integrity

Wireless monitoring enables real-time, remote marine asset integrity assessment with reduced installation costs and enhanced data flexibility compared to traditional wired sensor monitoring.

Network topology

Wireless monitoring enables flexible, easily scalable network topologies such as mesh or star, while wired sensor monitoring relies on fixed, linear or tree topologies constrained by physical cabling.

Wireless monitoring vs wired sensor monitoring Infographic

njnir.com

njnir.com