Hybrid propulsion systems in marine engineering combine internal combustion engines with electric motors, offering enhanced fuel efficiency and reduced emissions compared to direct drive propulsion, which relies solely on mechanical linkage from engine to propeller. This integration allows vessels to optimize power usage, switching between power sources based on operating conditions for improved environmental performance and operational flexibility. Direct drive propulsion, while simpler and often more reliable, typically results in higher fuel consumption and increased greenhouse gas emissions due to continuous mechanical power transmission.

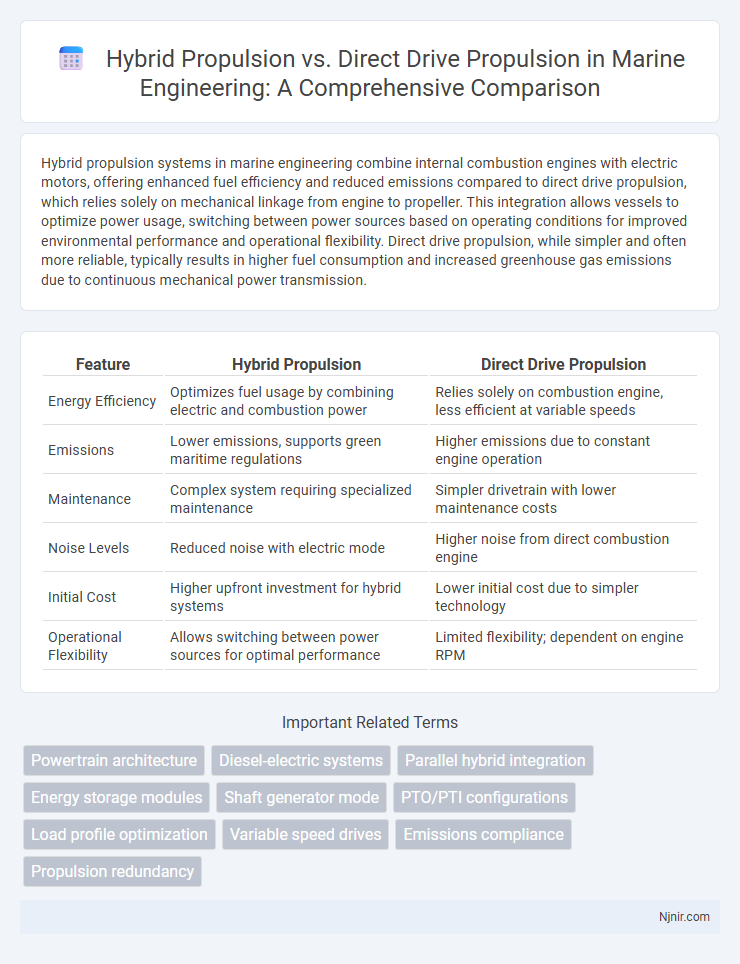

Table of Comparison

| Feature | Hybrid Propulsion | Direct Drive Propulsion |

|---|---|---|

| Energy Efficiency | Optimizes fuel usage by combining electric and combustion power | Relies solely on combustion engine, less efficient at variable speeds |

| Emissions | Lower emissions, supports green maritime regulations | Higher emissions due to constant engine operation |

| Maintenance | Complex system requiring specialized maintenance | Simpler drivetrain with lower maintenance costs |

| Noise Levels | Reduced noise with electric mode | Higher noise from direct combustion engine |

| Initial Cost | Higher upfront investment for hybrid systems | Lower initial cost due to simpler technology |

| Operational Flexibility | Allows switching between power sources for optimal performance | Limited flexibility; dependent on engine RPM |

Introduction to Marine Propulsion Technologies

Hybrid propulsion systems in marine applications combine traditional internal combustion engines with electric motors to enhance fuel efficiency and reduce emissions, making them increasingly popular for eco-friendly vessels. Direct drive propulsion directly connects the engine to the propeller shaft, offering mechanical simplicity, reliability, and high power transfer efficiency, favored in high-performance or heavy-duty marine vessels. Emerging marine propulsion technologies focus on optimizing energy consumption, improving environmental compliance, and integrating advanced control systems for enhanced vessel performance.

Overview of Hybrid Propulsion Systems

Hybrid propulsion systems combine traditional internal combustion engines with electric motors, optimizing fuel efficiency and reducing emissions. These systems enable seamless switching or simultaneous use of both power sources, enhancing performance in various driving conditions. Energy recovery technologies, such as regenerative braking, are integral in maximizing battery charge and overall system effectiveness in hybrid configurations.

Overview of Direct Drive Propulsion Systems

Direct drive propulsion systems eliminate the need for intermediate mechanical components by connecting the motor directly to the driven load, enhancing efficiency and reducing maintenance requirements. These systems offer higher torque density and improved reliability compared to hybrid propulsion, which combines multiple power sources but incurs complexity and energy losses. Direct drive technology is widely adopted in electric vehicles and industrial applications for its streamlined design and superior energy transfer.

Energy Efficiency Comparison

Hybrid propulsion systems combine electric motors with internal combustion engines, optimizing fuel consumption by using electric power during low-speed operations and engine power for higher speeds, resulting in significant energy savings compared to direct drive propulsion. Direct drive propulsion delivers power directly from the engine to the propeller, which can lead to higher energy losses due to less flexible speed control and increased fuel consumption under variable load conditions. Studies show hybrid systems achieve up to 25% greater energy efficiency in marine vessels and automotive applications by reducing emissions and maximizing fuel economy during stop-and-go and cruise phases.

Environmental Impact and Emissions

Hybrid propulsion systems significantly reduce environmental impact by combining internal combustion engines with electric motors, resulting in lower greenhouse gas emissions and improved fuel efficiency compared to direct drive propulsion. Direct drive propulsion typically relies solely on combustion engines, producing higher carbon dioxide and nitrogen oxides emissions due to continuous fuel consumption. The integration of electric power in hybrid systems enables regenerative braking and reduced idling, further minimizing pollutants and contributing to cleaner air quality.

Operational Flexibility and Performance

Hybrid propulsion systems combine electric motors with traditional engines, offering superior operational flexibility by enabling seamless switching between power sources for optimized fuel efficiency and reduced emissions. Direct drive propulsion provides a more straightforward mechanical setup, delivering consistent high performance with minimal energy loss due to fewer moving parts. Hybrid systems excel in variable load conditions and stop-and-go operations, while direct drive is favored for continuous high-speed performance and lower maintenance demands.

Maintenance and Lifecycle Costs

Hybrid propulsion systems typically incur higher initial maintenance costs due to complex components like generators, batteries, and power electronics, yet they often achieve lower lifecycle costs by improving fuel efficiency and reducing engine wear. Direct drive propulsion, characterized by simpler mechanical setups with fewer moving parts, generally requires less routine maintenance but may experience higher fuel consumption and increased wear over time, leading to elevated long-term expenses. Evaluating total cost of ownership involves balancing hybrid systems' upfront investments against potential savings in fuel and reduced engine overhauls over the vessel's operational life.

Space and Weight Considerations

Hybrid propulsion systems in spacecraft balance chemical and electric thrusters to optimize fuel efficiency and reduce overall mass, resulting in significant weight savings compared to traditional direct drive propulsion. Direct drive propulsion relies solely on one propulsion method, often leading to increased fuel mass and larger storage tanks, which significantly impact spacecraft weight and volume constraints. Hybrid systems enable more compact design by minimizing propellant requirements, directly influencing launch costs and mission payload capacity.

Application Suitability in Vessel Types

Hybrid propulsion systems excel in vessels requiring fuel efficiency and reduced emissions, such as ferries, offshore support vessels, and recreational yachts, where operational flexibility and environmental regulations are critical. Direct drive propulsion is more suited for high-speed vessels and large cargo ships that demand robust, continuous power delivery with minimal maintenance. The choice depends on vessel type, operational profile, and regulatory compliance, with hybrid systems favoring variable speed and fuel savings, while direct drive systems optimize reliability and simplicity for heavy-duty maritime applications.

Future Trends in Marine Propulsion

Future trends in marine propulsion indicate a significant shift toward hybrid propulsion systems, which combine internal combustion engines with electric motors to optimize fuel efficiency and reduce emissions. Direct drive propulsion remains favored for its mechanical simplicity and reliability in large vessels, but hybrid systems are increasingly integrated for enhanced environmental compliance and operational flexibility. Advances in energy storage technology and digital control systems are expected to accelerate the adoption of hybrid propulsion in commercial and recreational marine applications.

Powertrain architecture

Hybrid propulsion powertrain architectures combine internal combustion engines with electric motors for enhanced efficiency, while direct drive propulsion systems utilize a single motor directly connected to the wheels, reducing mechanical complexity and improving energy transfer.

Diesel-electric systems

Diesel-electric hybrid propulsion systems optimize fuel efficiency and reduce emissions compared to direct drive propulsion by combining diesel engines with electric motors for variable power demands.

Parallel hybrid integration

Parallel hybrid propulsion integrates an internal combustion engine and electric motor to optimize fuel efficiency and performance by allowing both power sources to simultaneously drive the vehicle.

Energy storage modules

Hybrid propulsion systems utilize energy storage modules combining batteries and fuel cells for enhanced energy density, while direct drive propulsion relies primarily on high-capacity batteries alone for energy storage.

Shaft generator mode

Hybrid propulsion's shaft generator mode optimizes fuel efficiency by generating electricity from the main engine shaft, reducing reliance on auxiliary generators compared to direct drive propulsion systems.

PTO/PTI configurations

Hybrid propulsion systems with Power Take-Off (PTO) and Power Take-In (PTI) configurations offer enhanced fuel efficiency and operational flexibility compared to direct drive propulsion by enabling selective electric motor assistance and regenerative energy recovery.

Load profile optimization

Hybrid propulsion systems optimize load profiles by dynamically balancing engine and electric motor output, improving fuel efficiency and reducing emissions compared to direct drive propulsion.

Variable speed drives

Variable speed drives in hybrid propulsion systems optimize energy efficiency and torque control compared to the fixed-speed operation of direct drive propulsion.

Emissions compliance

Hybrid propulsion systems significantly reduce emissions by combining electric and combustion power, enabling better compliance with stringent environmental regulations compared to conventional direct drive propulsion.

Propulsion redundancy

Hybrid propulsion systems provide greater propulsion redundancy by combining multiple independent power sources, whereas direct drive propulsion relies on a single powertrain, increasing vulnerability to complete propulsion failure.

hybrid propulsion vs direct drive propulsion Infographic

njnir.com

njnir.com