3D printing in marine engineering significantly reduces lead times and material waste compared to traditional manufacturing methods, enabling rapid prototyping and on-demand production of complex parts. This technology allows for the creation of lightweight, customized components that enhance vessel performance and fuel efficiency. Traditional manufacturing offers consistency and scalability but often lacks the flexibility and cost-effectiveness that additive manufacturing provides for intricate marine components.

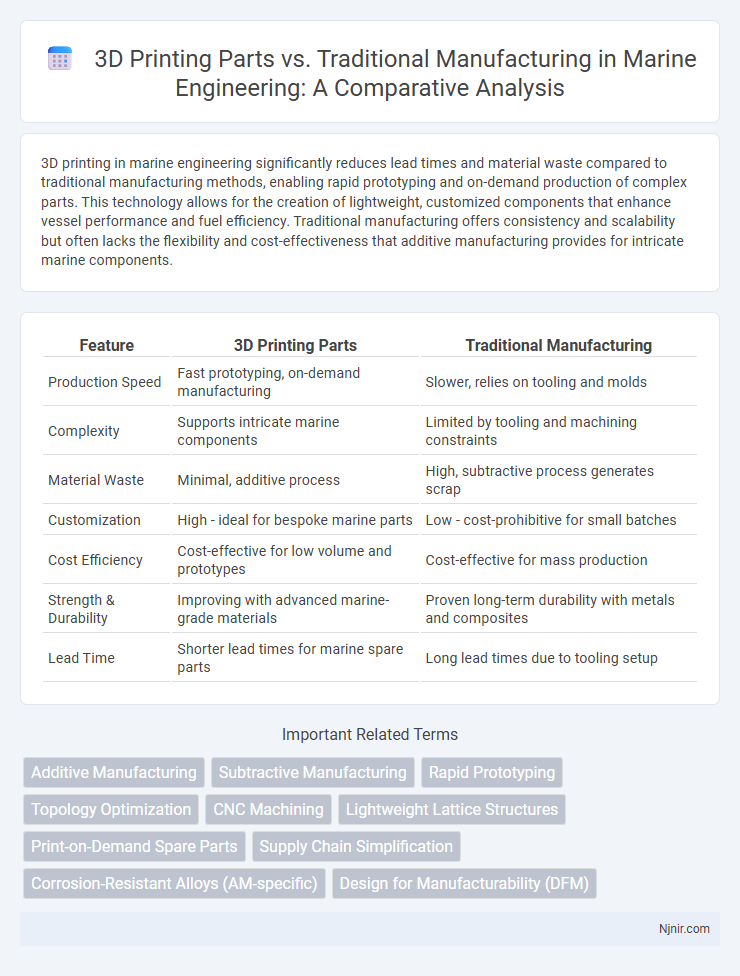

Table of Comparison

| Feature | 3D Printing Parts | Traditional Manufacturing |

|---|---|---|

| Production Speed | Fast prototyping, on-demand manufacturing | Slower, relies on tooling and molds |

| Complexity | Supports intricate marine components | Limited by tooling and machining constraints |

| Material Waste | Minimal, additive process | High, subtractive process generates scrap |

| Customization | High - ideal for bespoke marine parts | Low - cost-prohibitive for small batches |

| Cost Efficiency | Cost-effective for low volume and prototypes | Cost-effective for mass production |

| Strength & Durability | Improving with advanced marine-grade materials | Proven long-term durability with metals and composites |

| Lead Time | Shorter lead times for marine spare parts | Long lead times due to tooling setup |

Introduction to 3D Printing in Marine Engineering

3D printing in marine engineering offers rapid prototyping and on-demand production of complex, lightweight parts that traditional manufacturing struggles to achieve. This additive manufacturing process enables customization and reduces material waste by building components layer-by-layer from digital models. The integration of 3D printing accelerates component design cycles and improves maintenance efficiency for marine vessels and offshore structures.

Overview of Traditional Marine Manufacturing Methods

Traditional marine manufacturing methods rely heavily on casting, machining, and welding processes to produce metal parts with high strength and durability. These techniques are well-established in shipbuilding and offshore industries, enabling the fabrication of large-scale components like hulls, propellers, and engine parts with tight tolerances. Despite longer lead times and material wastage, traditional methods remain preferred for critical marine applications due to their proven reliability and standardized quality control.

Speed and Efficiency: 3D Printing vs Traditional Techniques

3D printing significantly reduces production time by enabling rapid prototyping and on-demand manufacturing, often completing complex parts in hours rather than days or weeks required by traditional machining or casting. Unlike conventional manufacturing, which involves multiple stages such as tooling setup and material waste, 3D printing offers streamlined workflows with minimal material usage and fewer assembly steps. This enhanced speed and efficiency make 3D printing ideal for low-volume production, customized components, and iterative design processes.

Material Choices and Marine Durability

3D printing parts utilize advanced polymer composites, titanium alloys, and corrosion-resistant plastics that offer superior resistance to saltwater and UV degradation compared to traditional steel and aluminum used in marine manufacturing. Marine durability in 3D printed components benefits from precise control over material composition and lattice structures, enhancing strength-to-weight ratios and reducing susceptibility to rust and galvanic corrosion. Traditional manufacturing methods often require protective coatings and regular maintenance to mitigate marine environment damage, whereas 3D printing enables tailored, inherently durable materials that improve longevity and performance in harsh sea conditions.

Cost Comparison: Additive vs Conventional Manufacturing

3D printing parts often reduce upfront costs by eliminating the need for expensive molds and tooling required in traditional manufacturing. Additive manufacturing minimizes material waste by building parts layer-by-layer, leading to lower raw material expenses compared to subtractive methods. However, conventional manufacturing can be more cost-effective for high-volume production due to economies of scale reducing per-unit costs.

Customization and Design Flexibility

3D printing parts offer unparalleled customization and design flexibility compared to traditional manufacturing, enabling the production of complex geometries and intricate details without additional tooling costs. Traditional manufacturing often relies on molds and subtractive processes that limit design variations and require significant setup time for each unique part. This flexibility in 3D printing accelerates prototyping, reduces material waste, and allows for rapid iteration, making it ideal for bespoke and low-volume production runs.

Weight Reduction and Performance Improvements

3D printing parts enable significant weight reduction through the use of lightweight materials and complex geometries unachievable by traditional manufacturing methods, leading to enhanced performance in sectors such as aerospace and automotive. This additive process allows for topology optimization, minimizing material usage while maintaining structural integrity, resulting in improved fuel efficiency and increased load capacity. In contrast, traditional manufacturing often involves subtractive methods that produce heavier components with less design flexibility, limiting opportunities for performance improvements.

Sustainability and Environmental Impact

3D printing parts significantly reduce material waste by utilizing additive manufacturing processes that build objects layer by layer, contrasting with traditional subtractive methods that generate excess scrap. This technology enables on-demand production, minimizing inventory and transportation emissions, which contributes to a lower carbon footprint. Moreover, 3D printing supports the use of recyclable and biodegradable materials, enhancing sustainability compared to the often non-recyclable raw materials used in conventional manufacturing.

Case Studies: Real-World Marine Applications

Case studies in real-world marine applications highlight the advantages of 3D printing parts over traditional manufacturing by demonstrating significant reductions in lead times and customizability for complex components such as propellers and engine housings. Companies like Rolls-Royce and Damen Shipyards report improved performance and maintenance efficiency through on-demand production of lightweight, corrosion-resistant parts using advanced materials like titanium alloys. These examples emphasize how additive manufacturing enables rapid prototyping and cost-effective small-batch production, transforming supply chain dynamics and operational readiness in the marine industry.

Future Trends in Marine Component Manufacturing

Future trends in marine component manufacturing emphasize the integration of 3D printing to enhance customization, reduce material waste, and accelerate production timelines compared to traditional manufacturing methods. Advanced additive manufacturing enables the creation of complex geometries and lightweight components that improve vessel performance and fuel efficiency. Ongoing developments in high-strength, corrosion-resistant materials also position 3D printing as a transformative technology for sustainable and cost-effective marine production.

Additive Manufacturing

Additive manufacturing enables cost-effective production of complex, customized 3D printed parts with reduced material waste and faster prototyping compared to traditional subtractive manufacturing methods.

Subtractive Manufacturing

Subtractive manufacturing removes material from a solid block to create parts with high precision, whereas 3D printing builds parts layer-by-layer, allowing complex geometries and reduced material waste.

Rapid Prototyping

3D printing enables rapid prototyping by significantly reducing production time and cost compared to traditional manufacturing methods, allowing faster iteration and design validation.

Topology Optimization

Topology optimization in 3D printing enables lightweight, structurally efficient parts with complex geometries unachievable by traditional manufacturing methods.

CNC Machining

CNC machining offers superior precision and material variety compared to 3D printing parts, making it ideal for high-tolerance applications in traditional manufacturing.

Lightweight Lattice Structures

Lightweight lattice structures produced by 3D printing offer superior strength-to-weight ratios and design flexibility compared to traditional manufacturing methods.

Print-on-Demand Spare Parts

Print-on-demand spare parts using 3D printing reduce inventory costs and lead times compared to traditional manufacturing by enabling rapid, on-site production of customized components.

Supply Chain Simplification

3D printing parts streamline supply chains by enabling on-demand production, reducing inventory costs, minimizing lead times, and eliminating the need for complex multi-tier sourcing compared to traditional manufacturing.

Corrosion-Resistant Alloys (AM-specific)

3D printing parts using corrosion-resistant alloys enable complex geometries with enhanced material efficiency and localized corrosion control compared to traditional manufacturing methods limited by machining and forging constraints.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) in 3D printing enables complex geometries and reduced assembly by minimizing tooling constraints, whereas traditional manufacturing requires design adaptations to accommodate tooling, machining, and material limitations.

3D printing parts vs Traditional manufacturing Infographic

njnir.com

njnir.com