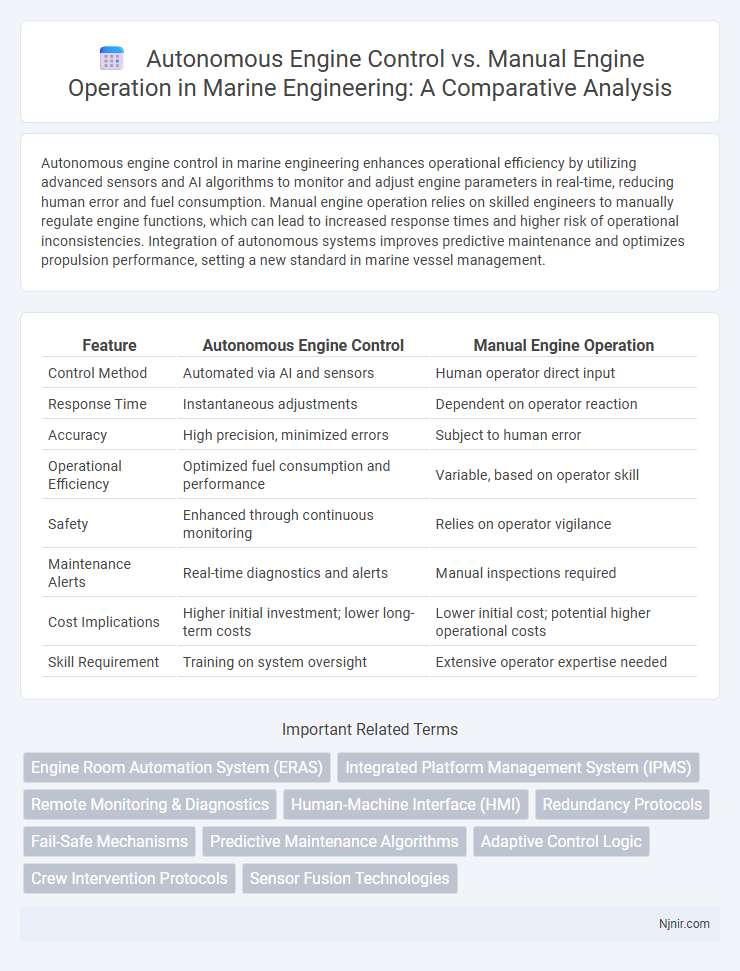

Autonomous engine control in marine engineering enhances operational efficiency by utilizing advanced sensors and AI algorithms to monitor and adjust engine parameters in real-time, reducing human error and fuel consumption. Manual engine operation relies on skilled engineers to manually regulate engine functions, which can lead to increased response times and higher risk of operational inconsistencies. Integration of autonomous systems improves predictive maintenance and optimizes propulsion performance, setting a new standard in marine vessel management.

Table of Comparison

| Feature | Autonomous Engine Control | Manual Engine Operation |

|---|---|---|

| Control Method | Automated via AI and sensors | Human operator direct input |

| Response Time | Instantaneous adjustments | Dependent on operator reaction |

| Accuracy | High precision, minimized errors | Subject to human error |

| Operational Efficiency | Optimized fuel consumption and performance | Variable, based on operator skill |

| Safety | Enhanced through continuous monitoring | Relies on operator vigilance |

| Maintenance Alerts | Real-time diagnostics and alerts | Manual inspections required |

| Cost Implications | Higher initial investment; lower long-term costs | Lower initial cost; potential higher operational costs |

| Skill Requirement | Training on system oversight | Extensive operator expertise needed |

Introduction to Engine Control Systems in Marine Engineering

Autonomous engine control systems in marine engineering leverage advanced sensors and real-time data processing to optimize performance, fuel efficiency, and emission standards while reducing human error. Manual engine operation relies heavily on skilled personnel for adjustments and monitoring, which can lead to inconsistencies and slower response times during critical maneuvers. Integration of electronic control units (ECUs) and automated feedback loops in autonomous systems ensures precise management of engine parameters, enhancing vessel safety and operational efficiency.

Fundamentals of Manual Engine Operation

Manual engine operation involves direct human intervention to control engine parameters such as throttle, fuel injection, and ignition timing, requiring skilled understanding of mechanical and thermodynamic principles. Operators must continuously monitor engine performance indicators like RPM, temperature, and pressure to optimize efficiency and prevent damage. This hands-on approach allows for immediate adjustments based on real-time feedback but demands consistent attention and expertise to maintain optimal engine functionality.

Overview of Autonomous Engine Control Systems

Autonomous engine control systems utilize advanced sensors, machine learning algorithms, and real-time data processing to optimize engine performance, fuel efficiency, and emissions reduction without human intervention. These systems continuously monitor parameters such as temperature, pressure, and combustion efficiency, allowing precise adjustments to fuel injection and ignition timing. Compared to manual engine operation, autonomous controls enhance reliability and adaptability under varying driving conditions, resulting in improved engine longevity and reduced maintenance costs.

Key Technologies Enabling Autonomy in Marine Engines

Autonomous engine control in marine engines relies heavily on advanced sensor integration, real-time data analytics, and machine learning algorithms to optimize performance and predict maintenance needs, contrasting with manual engine operation that depends on human intervention and routine checks. Key technologies enabling this autonomy include Internet of Things (IoT) devices for continuous monitoring, adaptive control systems that adjust parameters dynamically, and digital twin models simulating engine behavior for proactive decision-making. These innovations significantly enhance fuel efficiency, reduce emissions, and improve operational safety in marine vessels.

Operational Efficiency: Manual vs Autonomous Control

Autonomous engine control systems optimize fuel consumption and reduce operational errors by continuously adjusting parameters based on real-time data, leading to increased efficiency and lower maintenance costs compared to manual engine operation. Manual control relies heavily on operator skill and experience, which can result in inconsistent performance and higher fuel usage due to human error and delayed response times. Advanced sensor integration and AI-driven optimization enable autonomous engines to maintain optimal operational conditions, enhancing overall system reliability and productivity.

Safety and Reliability Considerations

Autonomous engine control systems enhance safety by continuously monitoring performance parameters and adjusting operations in real-time to prevent malfunctions and reduce human error. These systems improve reliability through predictive maintenance algorithms that detect potential failures before they occur, minimizing downtime and extending engine lifespan. Manual engine operation relies heavily on operator skill and vigilance, increasing the risk of inconsistent performance and delayed response to critical issues.

Human Factors and Crew Involvement

Autonomous engine control systems reduce human error by continuously monitoring performance metrics and adjusting parameters with precision beyond manual capabilities, enhancing overall safety and efficiency. However, reduced crew involvement may lead to skill degradation and reduced situational awareness, potentially impacting decision-making during unexpected events. Effective integration of autonomous controls requires balanced human-machine interaction protocols to maintain crew engagement while leveraging automation benefits.

Maintenance and Troubleshooting: Challenges and Solutions

Autonomous engine control systems enhance maintenance efficiency by continuously monitoring engine parameters through advanced sensors and predictive analytics, enabling early fault detection and reducing downtime compared to manual engine operation. Manual engine operation often requires intensive human intervention for troubleshooting, leading to increased risk of human error and longer diagnosis times. Implementing machine learning algorithms within autonomous systems addresses these challenges by offering real-time diagnostics and automated corrective actions, improving overall engine reliability and performance.

Regulatory and Compliance Implications

Autonomous engine control systems must adhere to stringent regulatory standards, including real-time monitoring, fail-safe mechanisms, and cybersecurity protocols mandated by agencies such as the U.S. EPA and the European Union's Emission Trading System (ETS). Manual engine operation allows for direct human intervention, often simplifying compliance with existing safety and emission regulations but limiting the integration of advanced diagnostics required for modern environmental standards. Compliance frameworks increasingly favor autonomous controls due to their ability to maintain continuous regulatory data reporting, reduce human error, and optimize engine performance for lower emissions and enhanced safety certifications.

Future Trends in Marine Engine Control Systems

Future trends in marine engine control systems emphasize the shift from manual engine operation to autonomous engine control, improving efficiency, safety, and environmental compliance. Advanced algorithms, machine learning integration, and real-time data analytics enable predictive maintenance and optimal performance adjustments in autonomous systems. Increasing adoption of IoT-enabled sensors and cloud-based monitoring supports remote diagnostics and decision-making, driving the evolution of smart marine propulsion technologies.

Engine Room Automation System (ERAS)

Engine Room Automation System (ERAS) enhances operational efficiency and safety by enabling autonomous engine control through real-time monitoring, predictive diagnostics, and automated adjustments compared to manual engine operation.

Integrated Platform Management System (IPMS)

Integrated Platform Management Systems (IPMS) enhance autonomous engine control by optimizing real-time monitoring, diagnostics, and automated adjustments compared to manual engine operation, resulting in improved efficiency, reduced human error, and increased system reliability.

Remote Monitoring & Diagnostics

Autonomous engine control integrates advanced remote monitoring and diagnostics systems to enable real-time performance analysis and predictive maintenance, significantly outperforming manual engine operation in efficiency and reliability.

Human-Machine Interface (HMI)

Autonomous engine control enhances Human-Machine Interface (HMI) by providing intuitive real-time feedback and adaptive control systems, reducing operator error compared to manual engine operation.

Redundancy Protocols

Autonomous engine control systems implement advanced redundancy protocols such as triple modular redundancy (TMR) and fail-operational fail-safe mechanisms to ensure continuous, error-free performance, whereas manual engine operation relies primarily on human intervention with limited real-time redundancy safeguards.

Fail-Safe Mechanisms

Autonomous engine control integrates advanced fail-safe mechanisms such as real-time diagnostics, automatic shutdown protocols, and redundant sensor systems, significantly reducing the risk of catastrophic failure compared to manual engine operation.

Predictive Maintenance Algorithms

Autonomous engine control leverages predictive maintenance algorithms, using real-time sensor data and machine learning to anticipate failures and optimize performance, whereas manual engine operation relies on scheduled inspections and reactive repairs, limiting efficiency and increasing downtime.

Adaptive Control Logic

Adaptive Control Logic in autonomous engine control dynamically adjusts performance parameters in real-time, enhancing fuel efficiency and engine durability compared to manual engine operation.

Crew Intervention Protocols

Autonomous engine control systems reduce the need for crew intervention by utilizing real-time sensor data and AI algorithms to optimize performance while manual engine operation relies heavily on defined crew intervention protocols to manage engine parameters and respond to anomalies.

Sensor Fusion Technologies

Sensor fusion technologies in autonomous engine control integrate data from multiple sensors to optimize performance, enhance safety, and reduce human error compared to manual engine operation.

Autonomous engine control vs manual engine operation Infographic

njnir.com

njnir.com