Corrosion monitoring in marine engineering focuses on detecting and preventing material degradation caused by chemical reactions with seawater, ensuring structural integrity and extending the lifespan of vessels. Vibration monitoring, on the other hand, involves analyzing mechanical oscillations within ship machinery to identify potential failures before they escalate. Combining corrosion and vibration monitoring enhances predictive maintenance strategies, reducing downtime and improving safety at sea.

Table of Comparison

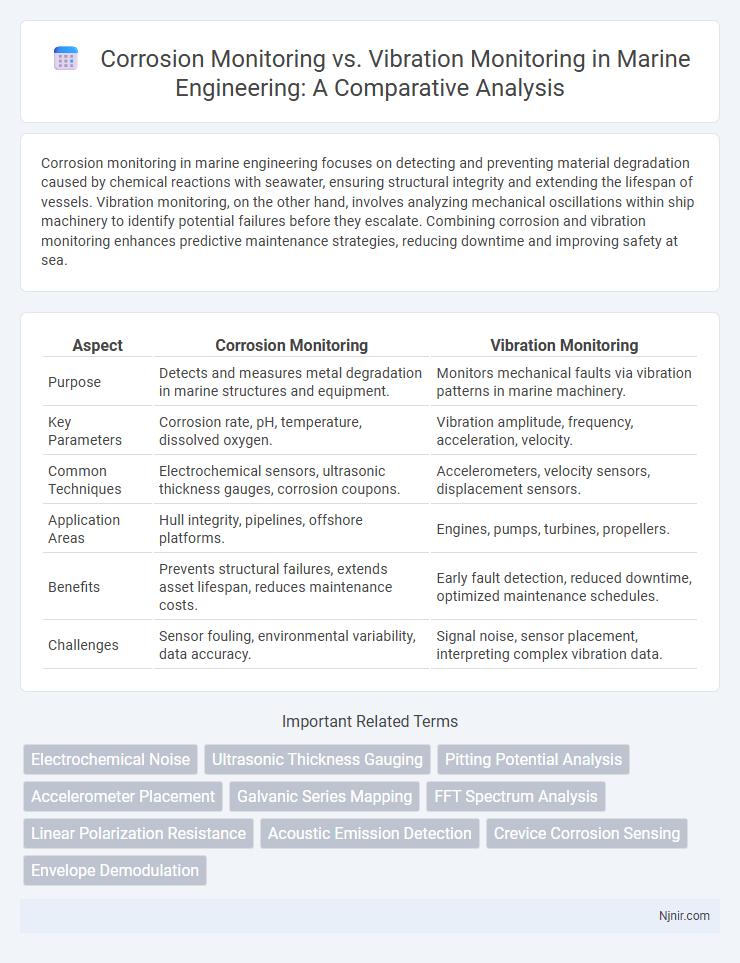

| Aspect | Corrosion Monitoring | Vibration Monitoring |

|---|---|---|

| Purpose | Detects and measures metal degradation in marine structures and equipment. | Monitors mechanical faults via vibration patterns in marine machinery. |

| Key Parameters | Corrosion rate, pH, temperature, dissolved oxygen. | Vibration amplitude, frequency, acceleration, velocity. |

| Common Techniques | Electrochemical sensors, ultrasonic thickness gauges, corrosion coupons. | Accelerometers, velocity sensors, displacement sensors. |

| Application Areas | Hull integrity, pipelines, offshore platforms. | Engines, pumps, turbines, propellers. |

| Benefits | Prevents structural failures, extends asset lifespan, reduces maintenance costs. | Early fault detection, reduced downtime, optimized maintenance schedules. |

| Challenges | Sensor fouling, environmental variability, data accuracy. | Signal noise, sensor placement, interpreting complex vibration data. |

Introduction to Marine Engineering Monitoring Systems

Corrosion monitoring and vibration monitoring are critical components of marine engineering monitoring systems, ensuring the structural integrity and operational reliability of vessels. Corrosion monitoring involves detecting and measuring the degradation of metal surfaces exposed to harsh marine environments, using sensors like corrosion probes and electrochemical techniques to prevent hull and equipment failure. Vibration monitoring tracks mechanical vibrations within engines and rotating machinery, utilizing accelerometers and signal analyzers to identify imbalances, misalignments, or bearing faults that could lead to breakdowns.

Overview of Corrosion Monitoring in Marine Environments

Corrosion monitoring in marine environments involves the continuous assessment of metal degradation due to saltwater exposure, biofouling, and oxygen concentration, which significantly impact the structural integrity of ships and offshore platforms. Techniques such as electrochemical sensors, ultrasonic thickness measurements, and corrosion coupons are employed to detect and quantify corrosion rates, enabling timely maintenance and preventing catastrophic failures. Regular corrosion monitoring reduces downtime and extends asset lifespan by providing critical data for informed decision-making in harsh marine conditions.

Fundamentals of Vibration Monitoring on Marine Vessels

Vibration monitoring on marine vessels involves measuring and analyzing the frequency, amplitude, and patterns of vibrations in machinery to detect early signs of mechanical faults such as imbalance, misalignment, or bearing failures. This method relies on sensors like accelerometers and velocity probes strategically placed on engines, propeller shafts, and auxiliary equipment to provide real-time data that helps prevent catastrophic failures and optimize maintenance schedules. Corrosion monitoring, by contrast, focuses on electrochemical techniques and visual inspections to assess material degradation, emphasizing metal loss and protective coating integrity rather than mechanical behavior.

Key Differences: Corrosion vs Vibration Monitoring

Corrosion monitoring tracks material degradation caused by chemical or electrochemical reactions, primarily focusing on metal loss and structural integrity over time. Vibration monitoring measures mechanical oscillations and frequency changes to detect imbalances, misalignments, or bearing faults in rotating equipment. The key difference lies in corrosion monitoring's emphasis on chemical wear, whereas vibration monitoring targets mechanical condition and equipment performance.

Technologies Used in Corrosion Monitoring

Corrosion monitoring technologies primarily include electrochemical sensors such as linear polarization resistance (LPR), electrochemical noise (EN), and electrical resistance (ER) probes, which provide real-time data on metal loss and corrosion rates. Ultrasonic thickness gauges and corrosion coupons are also widely utilized for assessing material degradation over time, offering non-intrusive and direct measurement methods. These technologies differ significantly from vibration monitoring, which relies on accelerometers and velocity sensors to detect mechanical faults rather than material integrity.

Technologies Used in Vibration Monitoring

Vibration monitoring primarily employs accelerometers, velocity sensors, and displacement probes to detect mechanical imbalances and machinery faults in real time. Advanced signal processing techniques such as Fast Fourier Transform (FFT) and envelope analysis enhance the accuracy of fault diagnosis by analyzing vibration frequency patterns. Wireless sensor networks and IoT-enabled devices further optimize vibration data collection and transmission for predictive maintenance in industrial applications.

Impact of Corrosion on Marine Equipment Reliability

Corrosion monitoring directly influences marine equipment reliability by detecting metal degradation that compromises structural integrity and accelerates failure rates in harsh saltwater environments. Vibration monitoring focuses on mechanical and operational anomalies but may miss early-stage corrosion that silently weakens components. Implementing corrosion monitoring enhances predictive maintenance strategies, reducing unplanned downtimes and extending marine asset lifespan.

Role of Vibration Analysis in Preventive Maintenance

Vibration analysis plays a critical role in preventive maintenance by detecting early signs of mechanical faults such as imbalance, misalignment, and bearing failures, enabling timely intervention before catastrophic failures occur. Unlike corrosion monitoring, which focuses on material degradation due to chemical reactions, vibration monitoring provides real-time insights into the dynamic behavior of rotating and reciprocating equipment. This proactive approach reduces downtime, extends equipment lifespan, and optimizes maintenance schedules in industrial operations.

Cost-Benefit Analysis: Corrosion vs Vibration Monitoring

Corrosion monitoring systems typically incur lower upfront costs but may require more frequent maintenance and replacement expenses due to material degradation, while vibration monitoring often involves higher initial investment in advanced sensor technology and signal processing. The cost-benefit analysis reveals corrosion monitoring provides substantial savings in infrastructure longevity and safety assurance, whereas vibration monitoring delivers superior predictive maintenance capabilities, reducing unexpected downtime and repair costs. Organizations must evaluate operational priorities and asset criticality to determine whether corrosion or vibration monitoring yields optimal return on investment for their specific industrial applications.

Future Trends in Marine Equipment Monitoring Systems

Future trends in marine equipment monitoring systems emphasize integrating corrosion monitoring with advanced vibration monitoring to provide comprehensive asset health insights. Emerging technologies such as AI-driven analytics and IoT-enabled sensors enhance real-time detection of both corrosion rates and vibration anomalies, improving predictive maintenance accuracy. Digital twins and machine learning models are increasingly employed to optimize lifespan predictions and reduce unplanned downtimes in marine vessels, driving a shift towards more proactive and condition-based monitoring strategies.

Electrochemical Noise

Electrochemical noise offers precise corrosion monitoring by detecting spontaneous fluctuations in corrosion processes, providing early warning signals that vibration monitoring cannot capture due to its focus on mechanical faults.

Ultrasonic Thickness Gauging

Ultrasonic Thickness Gauging provides precise corrosion monitoring by measuring material degradation, while vibration monitoring primarily detects mechanical faults without directly assessing corrosion levels.

Pitting Potential Analysis

Pitting Potential Analysis provides more precise early detection of localized corrosion compared to vibration monitoring, which primarily assesses mechanical integrity rather than electrochemical degradation.

Accelerometer Placement

Accelerometer placement in vibration monitoring is critical for detecting mechanical faults, whereas corrosion monitoring relies on strategically positioned sensors on metal surfaces to accurately track material degradation.

Galvanic Series Mapping

Galvanic Series Mapping enhances corrosion monitoring by identifying metal pairs prone to electrochemical reactions, offering a more precise assessment compared to vibration monitoring's mechanical wear detection.

FFT Spectrum Analysis

FFT spectrum analysis in vibration monitoring detects mechanical faults by identifying frequency components, while in corrosion monitoring it analyzes acoustic emissions or electrochemical signals to assess material degradation.

Linear Polarization Resistance

Linear Polarization Resistance provides precise corrosion rate measurements, offering direct electrochemical insights that complement vibration monitoring's mechanical stress analysis in predictive maintenance.

Acoustic Emission Detection

Acoustic Emission Detection in corrosion monitoring provides early crack and corrosion-related defect detection by capturing high-frequency stress waves, while vibration monitoring primarily detects mechanical faults through changes in vibration patterns.

Crevice Corrosion Sensing

Crevice corrosion sensing uses specialized corrosion monitoring techniques to detect localized metal degradation within confined spaces, while vibration monitoring primarily assesses mechanical integrity and may not effectively identify crevice corrosion issues.

Envelope Demodulation

Envelope demodulation enhances vibration monitoring by extracting failure signatures from modulated signals, while corrosion monitoring typically relies on electrochemical sensors, making envelope demodulation more critical for early fault detection in rotating machinery.

Corrosion monitoring vs Vibration monitoring Infographic

njnir.com

njnir.com