Hybrid propulsion systems in marine engineering combine traditional fuel engines with electric power, offering enhanced fuel efficiency and reduced emissions compared to conventional propulsion. These systems provide greater operational flexibility, allowing vessels to switch between power sources based on energy demands and environmental conditions. While conventional propulsion relies solely on fossil fuels, hybrid technologies support sustainable maritime operations and compliance with stricter environmental regulations.

Table of Comparison

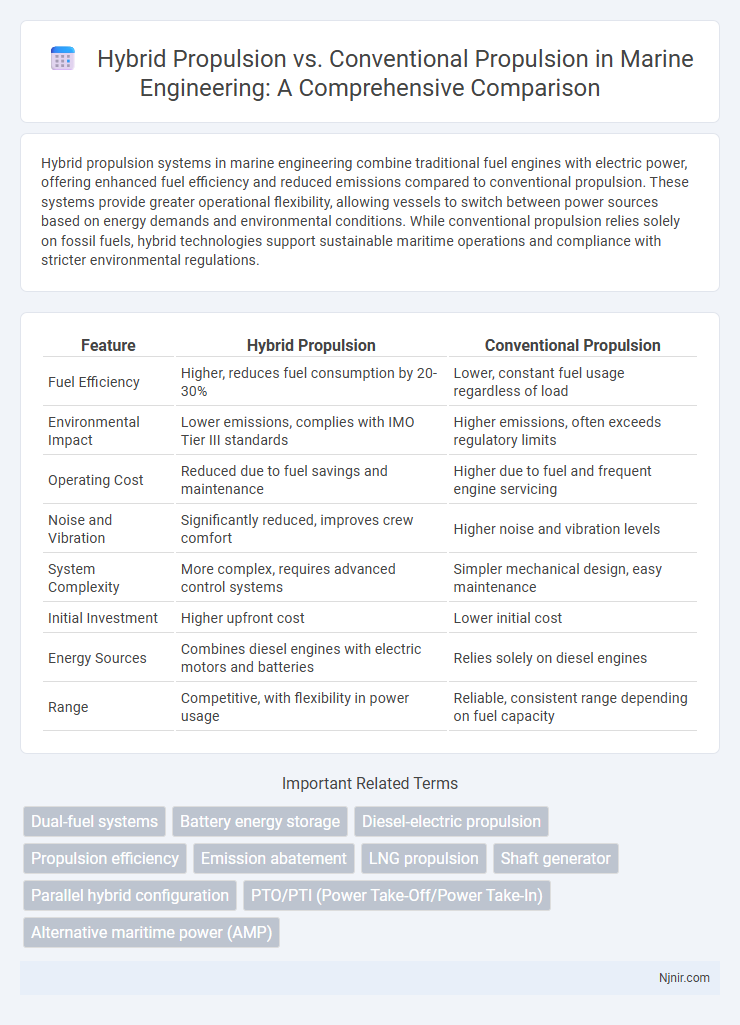

| Feature | Hybrid Propulsion | Conventional Propulsion |

|---|---|---|

| Fuel Efficiency | Higher, reduces fuel consumption by 20-30% | Lower, constant fuel usage regardless of load |

| Environmental Impact | Lower emissions, complies with IMO Tier III standards | Higher emissions, often exceeds regulatory limits |

| Operating Cost | Reduced due to fuel savings and maintenance | Higher due to fuel and frequent engine servicing |

| Noise and Vibration | Significantly reduced, improves crew comfort | Higher noise and vibration levels |

| System Complexity | More complex, requires advanced control systems | Simpler mechanical design, easy maintenance |

| Initial Investment | Higher upfront cost | Lower initial cost |

| Energy Sources | Combines diesel engines with electric motors and batteries | Relies solely on diesel engines |

| Range | Competitive, with flexibility in power usage | Reliable, consistent range depending on fuel capacity |

Introduction to Marine Propulsion Systems

Hybrid propulsion systems in marine vessels combine internal combustion engines with electric motors, optimizing fuel efficiency and reducing emissions compared to conventional propulsion that solely relies on diesel or gas engines. Marine propulsion technologies focus on maximizing thrust, minimizing fuel consumption, and meeting environmental regulations, with hybrids offering enhanced flexibility in power management and operational modes. Recent advancements in battery energy density and control systems have accelerated hybrid adoption, positioning it as a sustainable alternative to traditional marine propulsion methods.

Overview of Conventional Propulsion Technologies

Conventional propulsion technologies primarily rely on internal combustion engines that use fossil fuels such as gasoline or diesel to generate power through combustion processes. These systems deliver consistent power output and well-established infrastructure for fueling and maintenance, making them dominant in automotive and heavy-duty transportation sectors. Despite their efficiency and reliability, they contribute significantly to greenhouse gas emissions and face increasing regulatory pressure for reduced environmental impact.

Fundamentals of Hybrid Propulsion in Marine Vessels

Hybrid propulsion in marine vessels combines internal combustion engines with electric motors, optimizing fuel efficiency and reducing emissions compared to conventional propulsion systems that rely solely on diesel or gas engines. Energy recovery systems and battery storage play crucial roles in hybrid propulsion, enabling power management that adapts to variable operational demands and enhances overall system performance. This integration supports compliance with increasingly stringent environmental regulations while maintaining vessel speed and operational flexibility in diverse maritime conditions.

Key Components of Hybrid vs Conventional Systems

Hybrid propulsion systems integrate an internal combustion engine with an electric motor, battery pack, and power control unit, enabling energy regeneration and improved fuel efficiency. Conventional propulsion relies solely on an internal combustion engine with a fuel tank and transmission, lacking energy recovery mechanisms. The presence of electric components in hybrids allows for reduced emissions and enhanced performance compared to traditional engines.

Energy Efficiency and Fuel Consumption Comparison

Hybrid propulsion systems combine internal combustion engines with electric motors to optimize energy efficiency by recapturing and reusing energy during operation, significantly reducing fuel consumption compared to conventional propulsion. Conventional propulsion relies solely on fossil fuel engines that typically convert only a portion of fuel energy into useful work, resulting in higher fuel consumption and greater emissions. Studies indicate hybrid propulsion can improve fuel efficiency by 20-30%, making it a sustainable alternative for reducing operational costs and environmental impact.

Emissions and Environmental Impact Analysis

Hybrid propulsion systems significantly reduce greenhouse gas emissions compared to conventional propulsion by combining internal combustion engines with electric motors, leading to lower fuel consumption and decreased carbon dioxide output. Lifecycle analysis shows hybrid vehicles produce fewer pollutants like nitrogen oxides and particulate matter, mitigating urban air quality issues. Reduced reliance on fossil fuels in hybrids contributes to the overall decrease in environmental impact, supporting climate change mitigation efforts more effectively than conventional propulsion alone.

Operational Flexibility and Performance Considerations

Hybrid propulsion systems offer enhanced operational flexibility by combining internal combustion engines with electric motors, enabling quieter, low-emission operation during maneuvering and port activities while maintaining high power output for cruising. Conventional propulsion relies solely on internal combustion engines, which provide consistent and well-understood performance but lack the adaptability for varied power demands and environmental benefits. Performance considerations for hybrid systems include improved fuel efficiency and reduced emissions, whereas conventional propulsion often delivers higher peak power and simpler maintenance protocols.

Lifecycle Costs and Maintenance Requirements

Hybrid propulsion systems typically incur lower lifecycle costs due to improved fuel efficiency and reduced emissions compared to conventional propulsion, which often faces higher fuel and environmental compliance expenses. Maintenance requirements for hybrid systems are generally less intensive because electric components experience less wear, whereas conventional engines demand frequent servicing of mechanical parts. Over the vehicle's lifespan, hybrid propulsion offers long-term cost savings despite higher upfront investment, driven by decreased fuel consumption and maintenance frequency.

Case Studies: Real-World Applications and Success Stories

Hybrid propulsion systems, integrating electric motors with traditional internal combustion engines, have demonstrated significant efficiency improvements in case studies such as the Toyota Prius, which achieved a 35-40% increase in fuel economy compared to conventional vehicles. In maritime applications, hybrid propulsion has reduced fuel consumption by up to 30% and lowered emissions, as evidenced by the MV Viking Grace ferry operating in the Baltic Sea. Case studies in aviation also reveal that hybrid-electric prototypes like the Zunum Aero project aim to cut carbon emissions by up to 50%, showcasing the transformative potential of hybrid propulsion across transportation sectors.

Future Trends and Innovations in Marine Propulsion

Hybrid propulsion systems in marine vessels integrate electric motors with traditional engines, significantly reducing fuel consumption and emissions compared to conventional propulsion. Emerging innovations such as advanced battery technologies, hydrogen fuel cells, and AI-driven energy management are accelerating the shift towards sustainable and efficient hybrid marine propulsion. Future trends indicate a growing adoption of hybrid systems powered by renewable energy sources, enhancing operational flexibility and meeting stringent environmental regulations.

Dual-fuel systems

Dual-fuel hybrid propulsion systems significantly reduce emissions and fuel consumption by seamlessly alternating between conventional fuels and alternative energy sources, optimizing efficiency and environmental performance.

Battery energy storage

Hybrid propulsion systems use advanced battery energy storage to increase efficiency and reduce emissions compared to conventional propulsion relying solely on fossil fuels.

Diesel-electric propulsion

Diesel-electric hybrid propulsion systems combine diesel engines with electric motors to enhance fuel efficiency, reduce emissions, and improve maneuverability compared to conventional diesel-only propulsion systems.

Propulsion efficiency

Hybrid propulsion systems achieve higher propulsion efficiency than conventional propulsion by combining electric motors with internal combustion engines to optimize power use and reduce fuel consumption.

Emission abatement

Hybrid propulsion systems reduce emissions by combining electric motors with conventional engines, significantly lowering carbon dioxide and nitrogen oxide output compared to traditional solely fuel-based propulsion.

LNG propulsion

Hybrid propulsion systems combining LNG with conventional fuels significantly reduce emissions and enhance fuel efficiency compared to traditional LNG-only propulsion in maritime vessels.

Shaft generator

Hybrid propulsion with integrated shaft generators enhances fuel efficiency and reduces emissions compared to conventional propulsion by enabling optimized energy management and load sharing.

Parallel hybrid configuration

Parallel hybrid propulsion systems combine an internal combustion engine and electric motor connected to the drivetrain, optimizing fuel efficiency and reducing emissions compared to conventional propulsion by enabling simultaneous or independent power delivery.

PTO/PTI (Power Take-Off/Power Take-In)

Hybrid propulsion systems with PTO/PTI functionality enable efficient energy recovery and auxiliary power generation, outperforming conventional propulsion by reducing fuel consumption and emissions through regenerative braking and electric motor integration.

Alternative maritime power (AMP)

Hybrid propulsion systems with Alternative Maritime Power (AMP) significantly reduce emissions and fuel consumption compared to conventional propulsion by enabling ships to plug into shore power while docked.

Hybrid propulsion vs Conventional propulsion Infographic

njnir.com

njnir.com