Exhaust gas recirculation (EGR) reduces nitrogen oxide emissions by recirculating a portion of the engine's exhaust gas back into the combustion chamber, lowering combustion temperatures and improving fuel efficiency. Wet scrubbers remove sulfur oxides and particulate matter from exhaust gases by using a liquid spray, effectively reducing air pollution in marine engines. Both systems are essential for meeting stringent marine emission regulations and enhancing environmental sustainability.

Table of Comparison

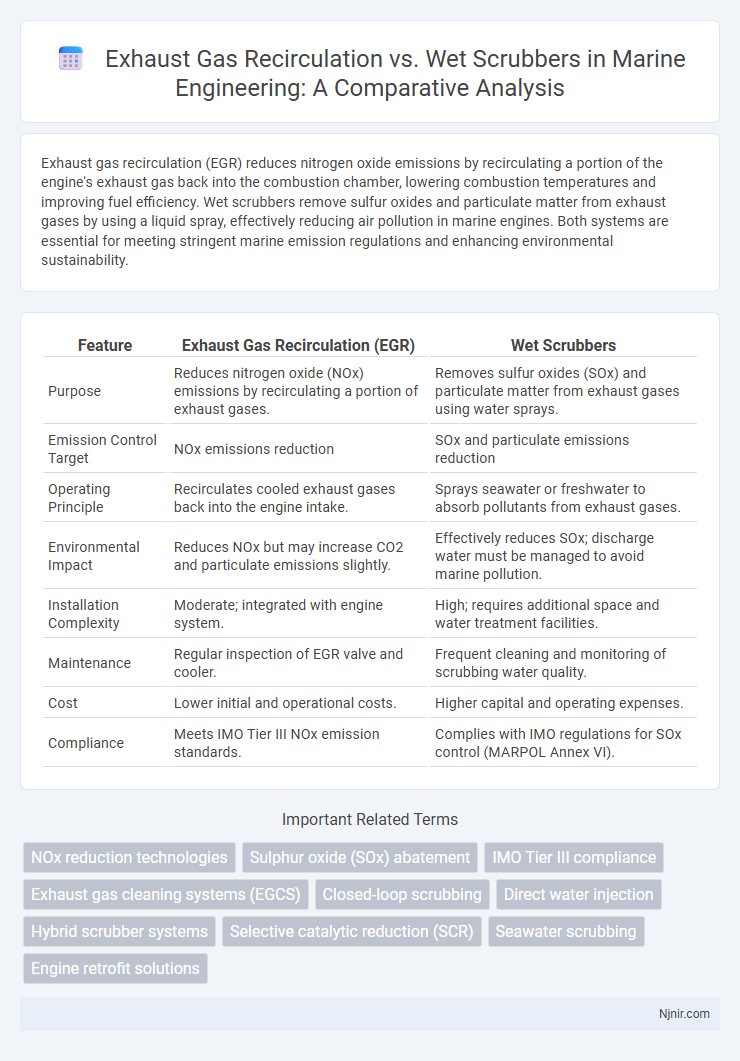

| Feature | Exhaust Gas Recirculation (EGR) | Wet Scrubbers |

|---|---|---|

| Purpose | Reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases. | Removes sulfur oxides (SOx) and particulate matter from exhaust gases using water sprays. |

| Emission Control Target | NOx emissions reduction | SOx and particulate emissions reduction |

| Operating Principle | Recirculates cooled exhaust gases back into the engine intake. | Sprays seawater or freshwater to absorb pollutants from exhaust gases. |

| Environmental Impact | Reduces NOx but may increase CO2 and particulate emissions slightly. | Effectively reduces SOx; discharge water must be managed to avoid marine pollution. |

| Installation Complexity | Moderate; integrated with engine system. | High; requires additional space and water treatment facilities. |

| Maintenance | Regular inspection of EGR valve and cooler. | Frequent cleaning and monitoring of scrubbing water quality. |

| Cost | Lower initial and operational costs. | Higher capital and operating expenses. |

| Compliance | Meets IMO Tier III NOx emission standards. | Complies with IMO regulations for SOx control (MARPOL Annex VI). |

Introduction to Marine Emission Control Technologies

Exhaust gas recirculation (EGR) and wet scrubbers are critical marine emission control technologies designed to reduce harmful pollutants from ship exhaust. EGR systems lower nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine combustion chamber, thereby reducing combustion temperatures. Wet scrubbers, or exhaust gas cleaning systems, remove sulfur oxides (SOx) and particulate matter by spraying seawater or freshwater to neutralize and capture pollutants before release into the atmosphere.

Overview of Exhaust Gas Recirculation (EGR)

Exhaust Gas Recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of an engine's exhaust gas back to the engine cylinders, lowering combustion temperatures and oxygen levels. EGR systems are widely used in internal combustion engines, especially in diesel and gasoline engines, to enhance emission control and comply with environmental regulations. Unlike wet scrubbers, which physically remove pollutants through liquid absorption, EGR focuses on reducing pollutant formation at the source during the combustion process.

Overview of Wet Scrubber Systems

Wet scrubber systems utilize liquid solutions, typically water, to capture pollutants and particulate matter from exhaust gases by means of direct contact and absorption. These systems effectively remove sulfur dioxide (SO2), hydrogen chloride (HCl), and particulate pollutants, making them suitable for industrial applications such as power plants and chemical manufacturing. Compared to Exhaust Gas Recirculation (EGR), which reduces nitrogen oxides (NOx) by recirculating a portion of exhaust gases back into the combustion chamber, wet scrubbers excel in controlling acidic gases and particulate emissions in flue gas streams.

Regulatory Compliance: EGR vs Wet Scrubbers

Exhaust Gas Recirculation (EGR) systems reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine combustion chamber, effectively lowering combustion temperatures and meeting stringent emission standards such as Euro 6 and EPA Tier 4. Wet scrubbers, utilized predominantly in industrial and marine applications, remove particulate matter and sulfur oxides (SOx) from exhaust streams by using liquid spray, enabling compliance with regulations like the IMO 2020 sulfur cap and local air quality standards. While EGR targets NOx emissions primarily in internal combustion engines, wet scrubbers provide a broader pollutant removal solution aligned with varied industrial emission regulations.

Operational Efficiency and Performance Comparison

Exhaust gas recirculation (EGR) improves operational efficiency by reducing nitrogen oxide (NOx) emissions through internal combustion modifications, leading to lower fuel consumption and enhanced engine performance. Wet scrubbers excel at removing particulate matter and sulfur dioxide (SO2) from exhaust gases by using liquid solutions, but they require higher maintenance and energy input. Comparing performance, EGR offers more efficient fuel use and direct emission reduction, while wet scrubbers provide extensive pollutant removal with increased operational complexity and cost.

Environmental Impact Assessment

Exhaust gas recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of engine exhaust gases back into the combustion chamber, thereby lowering combustion temperatures and minimizing the formation of pollutants. Wet scrubbers effectively remove particulate matter, sulfur dioxide (SO2), and other acidic gases from industrial exhaust streams by using liquid sprays, resulting in significant reductions in air pollutants that contribute to acid rain and respiratory issues. Environmental impact assessments highlight that EGR primarily targets combustion-related NOx emissions, while wet scrubbers provide broader remediation of multiple pollutants, making both systems complementary for comprehensive emission control strategies.

Installation and Maintenance Considerations

Exhaust gas recirculation (EGR) systems require precise integration with engine components, involving complex installation to ensure optimal emission control and engine performance. Maintenance of EGR systems demands regular cleaning to prevent soot buildup and component wear, increasing operational costs and downtime. Wet scrubbers, by contrast, involve simpler installation with external units that treat exhaust gases, and their maintenance centers on periodic replacement of scrubbing liquid and handling of collected pollutants.

Cost-Benefit Analysis: EGR and Wet Scrubbers

Exhaust Gas Recirculation (EGR) systems typically offer lower operational costs by reducing nitrogen oxide emissions through internal engine modifications without adding significant external hardware. Wet scrubbers, although more expensive in installation and maintenance due to their complex water treatment and disposal requirements, provide comprehensive removal of particulate matter and sulfur dioxide, making them cost-effective in industries with high sulfur fuel usage. The cost-benefit analysis favors EGR for vehicles and smaller engines due to fuel efficiency and reduced emissions, while wet scrubbers deliver superior pollutant removal for large-scale industrial applications despite higher upfront and ongoing expenses.

Case Studies and Industry Applications

Case studies in automotive manufacturing reveal that Exhaust Gas Recirculation (EGR) systems effectively reduce nitrogen oxide emissions by recirculating a portion of exhaust gases back into the engine cylinders, enhancing combustion efficiency. In contrast, wet scrubbers are widely applied in the chemical and power generation industries to remove particulate matter and acidic gases from industrial exhaust streams through liquid absorption. Industry applications demonstrate that EGR is optimal for internal combustion engines targeting emission compliance, whereas wet scrubbers excel in large-scale industrial pollution control where multi-pollutant removal is required.

Future Trends in Marine Emission Reduction Technologies

Exhaust gas recirculation (EGR) and wet scrubbers represent critical technologies in the future of marine emission reduction, targeting nitrogen oxides (NOx) and sulfur oxides (SOx) respectively. Emerging trends emphasize integrating advanced EGR systems with optimized wet scrubber designs to meet stringent International Maritime Organization (IMO) regulations, reducing greenhouse gas emissions and particulate matter from shipping vessels. Innovations in real-time emission monitoring and hybrid technologies combining EGR and scrubbers enhance operational efficiency and environmental compliance in the evolving maritime industry.

NOx reduction technologies

Exhaust gas recirculation (EGR) reduces NOx emissions by recirculating a portion of exhaust gases to lower combustion temperatures, while wet scrubbers eliminate NOx through chemical absorption using alkaline solutions.

Sulphur oxide (SOx) abatement

Exhaust gas recirculation reduces nitrogen oxides but is less effective than wet scrubbers, which achieve up to 95% removal of sulphur oxides (SOx) in industrial emissions.

IMO Tier III compliance

Exhaust gas recirculation (EGR) and wet scrubbers both enable IMO Tier III compliance by effectively reducing NOx and SOx emissions, with EGR targeting NOx reduction through recirculated exhaust gases and wet scrubbers removing SOx via chemical absorption in a liquid medium.

Exhaust gas cleaning systems (EGCS)

Exhaust gas recirculation (EGR) reduces nitrogen oxide emissions by recirculating a portion of exhaust gases back to the engine, while wet scrubbers in Exhaust Gas Cleaning Systems (EGCS) use seawater to remove sulfur oxides and particulate matter from ship emissions, providing complementary approaches to marine pollution control.

Closed-loop scrubbing

Closed-loop scrubbing in wet scrubbers offers superior exhaust gas recirculation by efficiently removing pollutants through chemical reactions without releasing contaminated wash water, unlike traditional EGR systems that recirculate exhaust gases but may increase particulate and NOx emissions.

Direct water injection

Direct water injection in exhaust gas recirculation (EGR) systems enhances emission control efficiency by reducing nitrogen oxide (NOx) formation, whereas wet scrubbers primarily focus on removing particulate matter and acid gases through liquid absorption.

Hybrid scrubber systems

Hybrid scrubber systems combine exhaust gas recirculation with wet scrubbers to optimize emissions reduction by simultaneously lowering nitrogen oxides and particulate matter in marine and industrial exhaust streams.

Selective catalytic reduction (SCR)

Selective catalytic reduction (SCR) achieves higher nitrogen oxide (NOx) reduction efficiency than exhaust gas recirculation (EGR) and wet scrubbers by chemically converting NOx into nitrogen and water using a catalyst and reductant such as ammonia or urea.

Seawater scrubbing

Seawater scrubbing in exhaust gas recirculation systems effectively reduces sulfur oxides emissions by utilizing natural alkalinity, offering an environmentally friendly alternative to traditional wet scrubbers.

Engine retrofit solutions

Exhaust gas recirculation (EGR) systems retrofit engines by recirculating a portion of exhaust gases to reduce NOx emissions, while wet scrubbers retrofit involves adding liquid spray technology to capture particulate matter and sulfur oxides from exhaust streams for enhanced pollution control.

Exhaust gas recirculation vs Wet scrubbers Infographic

njnir.com

njnir.com