Controllable Pitch Propellers (CPP) offer superior maneuverability and fuel efficiency compared to Fixed Pitch Propellers (FPP) by allowing precise adjustment of blade angles to match varying operating conditions. CPP systems enhance vessel performance during low-speed operations and improve reverse thrust capabilities, reducing the need for engine speed changes. Fixed Pitch Propellers, while simpler and more robust, lack flexibility in blade pitch adjustments, resulting in less optimal efficiency across diverse sailing speeds and load conditions.

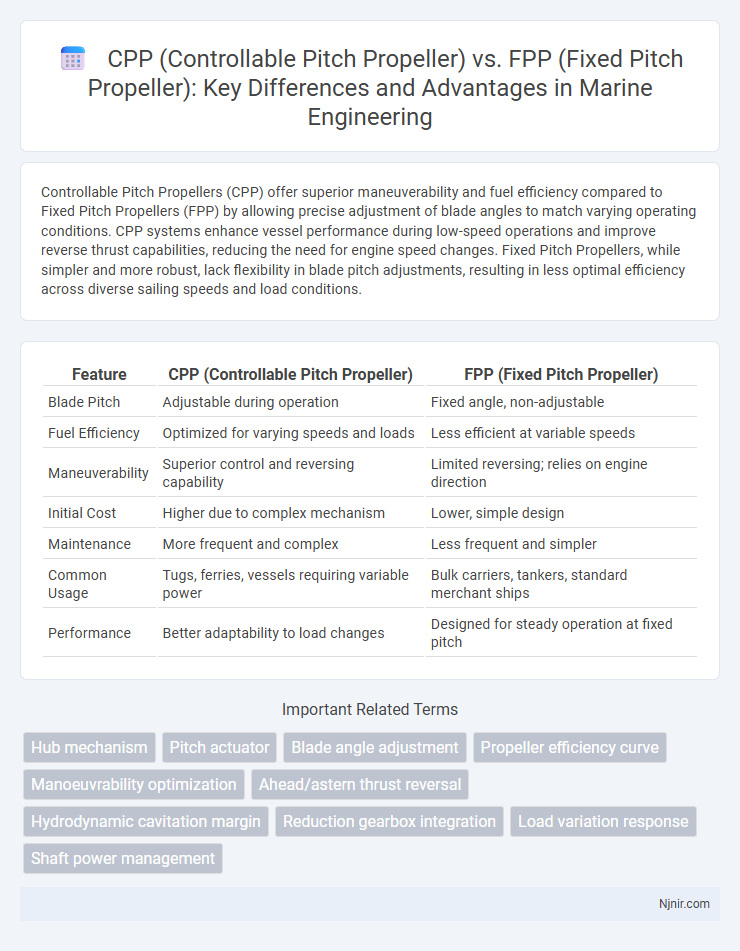

Table of Comparison

| Feature | CPP (Controllable Pitch Propeller) | FPP (Fixed Pitch Propeller) |

|---|---|---|

| Blade Pitch | Adjustable during operation | Fixed angle, non-adjustable |

| Fuel Efficiency | Optimized for varying speeds and loads | Less efficient at variable speeds |

| Maneuverability | Superior control and reversing capability | Limited reversing; relies on engine direction |

| Initial Cost | Higher due to complex mechanism | Lower, simple design |

| Maintenance | More frequent and complex | Less frequent and simpler |

| Common Usage | Tugs, ferries, vessels requiring variable power | Bulk carriers, tankers, standard merchant ships |

| Performance | Better adaptability to load changes | Designed for steady operation at fixed pitch |

Introduction to Marine Propeller Systems

Controllable Pitch Propellers (CPP) enable variable blade angles for optimal thrust and fuel efficiency across diverse operating conditions, enhancing vessel maneuverability and performance. Fixed Pitch Propellers (FPP) have a fixed blade angle designed for a specific speed and load, offering simplicity, lower initial cost, and reliability in steady-state operations. Marine propulsion systems benefit from CPP when frequent speed and directional changes occur, while FPP suits applications with consistent sailing profiles and reduced maintenance complexity.

Overview of Controllable Pitch Propellers (CPP)

Controllable Pitch Propellers (CPP) offer adjustable blade angles, enabling precise thrust control and improved fuel efficiency across varying engine loads and vessel speeds. Unlike Fixed Pitch Propellers (FPP), CPP systems allow reversing thrust without changing engine rotation, enhancing maneuverability in ships like tugs, ferries, and offshore vessels. This adaptability reduces drivetrain stress and optimizes performance, making CPP a preferred choice for vessels requiring frequent speed and directional changes.

Overview of Fixed Pitch Propellers (FPP)

Fixed Pitch Propellers (FPP) feature blades with a fixed angle that cannot be altered during operation, providing simplicity, durability, and lower maintenance costs compared to Controllable Pitch Propellers (CPP). FPPs are highly efficient at a constant design speed and load, making them ideal for vessels with steady operating profiles such as cargo ships and tankers. The rigidity in blade pitch delivers reliable thrust and propulsion efficiency but limits maneuverability and fuel optimization under varying conditions.

Key Differences Between CPP and FPP

Controllable Pitch Propellers (CPP) enable adjustment of blade angles during operation, allowing for improved maneuverability, fuel efficiency, and optimized performance across varying speeds and loads. Fixed Pitch Propellers (FPP) have blades set at a fixed angle, offering simplicity, lower initial cost, and robustness but lack the flexibility to adapt to different operating conditions. CPP systems require more complex mechanical components and maintenance compared to the simpler and more durable design of FPP systems.

Efficiency and Performance Comparison

Controllable Pitch Propellers (CPP) offer superior efficiency across varying speeds and load conditions by allowing blade pitch adjustments, optimizing thrust and fuel consumption compared to Fixed Pitch Propellers (FPP), which operate efficiently only at a specific design point. CPP systems enhance vessel maneuverability and reduce engine wear due to flexible power control, making them ideal for applications requiring frequent speed changes or precise handling. In contrast, FPPs deliver simpler maintenance and lower initial costs but sacrifice performance adaptability and overall fuel efficiency in diverse operating conditions.

Operational Flexibility and Maneuverability

Controllable Pitch Propellers (CPP) offer superior operational flexibility by allowing real-time adjustment of blade angles, enabling precise thrust modulation without changing engine speed, ideal for varied marine conditions. Fixed Pitch Propellers (FPP) have a constant blade angle, resulting in less adaptability during speed and load changes, which limits maneuverability especially in tight or complex navigational environments. CPP systems enhance maneuverability by facilitating quick reverse thrust and fine-tuned speed control, crucial for docking and complex vessel operations.

Maintenance and Lifecycle Costs

Controllable Pitch Propellers (CPP) generally incur higher maintenance costs due to their complex pitch-changing mechanisms, including hydraulic systems and bearing assemblies that require regular inspection and servicing. Fixed Pitch Propellers (FPP) have simpler designs with fewer moving parts, resulting in lower routine maintenance and longer intervals between overhauls. Lifecycle costs of CPP can be offset by enhanced fuel efficiency and maneuverability benefits, while FPP presents lower upfront and ongoing maintenance expenditures but less operational flexibility.

Application Suitability: When to Use CPP or FPP

Controllable Pitch Propellers (CPP) are ideal for vessels requiring frequent speed adjustments and precise maneuverability, such as tugboats, ferries, and offshore supply ships. Fixed Pitch Propellers (FPP) offer superior efficiency in steady-speed operations, making them suitable for bulk carriers, tankers, and container ships with consistent cruising speeds. Selecting between CPP and FPP depends on the vessel's operational profile, with CPP favored for versatility and FPP for fuel-efficient, long-haul journeys.

Environmental Impact and Fuel Consumption

Controllable Pitch Propellers (CPP) enhance fuel efficiency by optimizing blade angles to match varying operational conditions, reducing fuel consumption and lowering greenhouse gas emissions compared to Fixed Pitch Propellers (FPP), which operate at a constant blade angle and often cause suboptimal engine loads. CPP systems enable precise thrust control, minimizing cavitation and noise pollution, thereby contributing to reduced environmental impact. In contrast, FPPs typically result in higher fuel burn and increased CO2 emissions due to less efficient propulsion under changing speeds and loads.

Future Trends in Marine Propulsion Technology

Controllable Pitch Propellers (CPP) offer enhanced fuel efficiency and maneuverability compared to Fixed Pitch Propellers (FPP), aligning with future marine propulsion trends emphasizing sustainability and operational flexibility. Innovations in smart CPP systems integrate real-time performance analytics and adaptive pitch control, reducing emissions and optimizing power use in varying sea conditions. The marine industry increasingly adopts hybrid propulsion solutions combining CPP with electric drives, supporting decarbonization goals and stricter environmental regulations.

Hub mechanism

The hub mechanism of CPP integrates adjustable blades allowing real-time pitch control for enhanced maneuverability, whereas FPP features a solid hub with fixed blades optimized for consistent efficiency and simpler maintenance.

Pitch actuator

Controllable Pitch Propellers (CPP) use hydraulic or electric pitch actuators to adjust blade angles dynamically, enhancing fuel efficiency and maneuverability, whereas Fixed Pitch Propellers (FPP) have fixed blades with no pitch actuator, limiting operational flexibility.

Blade angle adjustment

CPP (Controllable Pitch Propeller) enables real-time blade angle adjustment for optimal thrust and fuel efficiency, whereas FPP (Fixed Pitch Propeller) has a fixed blade angle limiting operational flexibility.

Propeller efficiency curve

Controllable Pitch Propellers (CPP) maintain higher propeller efficiency across a wider range of operating speeds compared to Fixed Pitch Propellers (FPP), which have peak efficiency at a single optimized point on their fixed blade angle efficiency curve.

Manoeuvrability optimization

Controllable Pitch Propellers (CPP) optimize maneuverability by allowing precise blade angle adjustments for rapid thrust changes, unlike Fixed Pitch Propellers (FPP) which have fixed blade angles limiting responsiveness and efficiency in variable operating conditions.

Ahead/astern thrust reversal

CPP offers precise ahead and astern thrust reversal by adjusting blade pitch dynamically, while FPP requires engine direction change or gearbox reversal for thrust reversal, limiting maneuverability and response time.

Hydrodynamic cavitation margin

Controllable Pitch Propellers (CPP) offer improved hydrodynamic cavitation margin compared to Fixed Pitch Propellers (FPP) by enabling pitch adjustments that optimize blade loading and minimize pressure fluctuations around the blades.

Reduction gearbox integration

Controllable Pitch Propellers (CPP) integrate with reduction gearboxes to allow variable blade angles and enhanced maneuverability, while Fixed Pitch Propellers (FPP) rely on fixed blade angles, typically resulting in simpler, more robust gearbox designs optimized for consistent RPM transmission.

Load variation response

Controllable Pitch Propellers (CPP) rapidly adjust blade angles to optimize thrust under varying load conditions, providing superior load variation response compared to Fixed Pitch Propellers (FPP) which rely on engine speed changes for thrust adjustment.

Shaft power management

Controllable Pitch Propellers (CPP) enable precise shaft power management by adjusting blade angles for optimal engine load and fuel efficiency, whereas Fixed Pitch Propellers (FPP) rely on engine speed variation, limiting shaft power control and efficiency optimization.

CPP (Controllable Pitch Propeller) vs FPP (Fixed Pitch Propeller) Infographic

njnir.com

njnir.com