Single screw propulsion systems offer simplicity, lower initial cost, and reduced maintenance compared to twin screw arrangements. Twin screw configurations provide enhanced maneuverability, improved redundancy, and better efficiency at high speeds, making them ideal for larger vessels or those requiring precise handling. Choosing between single and twin screw arrangements depends on vessel size, operational requirements, and performance priorities.

Table of Comparison

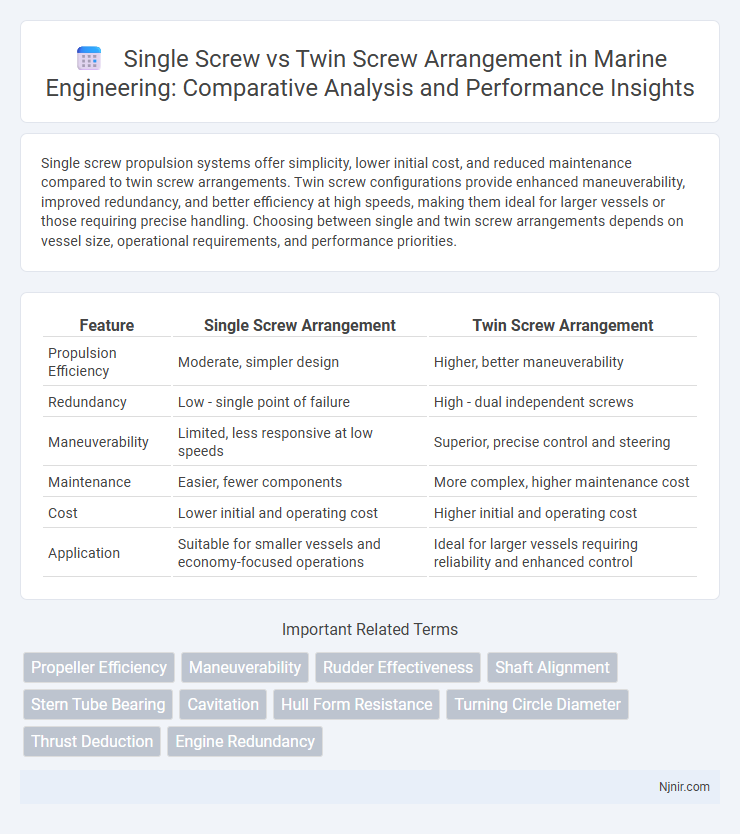

| Feature | Single Screw Arrangement | Twin Screw Arrangement |

|---|---|---|

| Propulsion Efficiency | Moderate, simpler design | Higher, better maneuverability |

| Redundancy | Low - single point of failure | High - dual independent screws |

| Maneuverability | Limited, less responsive at low speeds | Superior, precise control and steering |

| Maintenance | Easier, fewer components | More complex, higher maintenance cost |

| Cost | Lower initial and operating cost | Higher initial and operating cost |

| Application | Suitable for smaller vessels and economy-focused operations | Ideal for larger vessels requiring reliability and enhanced control |

Introduction to Marine Propulsion Systems

Single screw marine propulsion systems utilize one propeller connected to the engine, offering simplicity, lower initial cost, and easier maintenance for small to medium-sized vessels. Twin screw arrangements feature two propellers powered by separate engines or a split power source, providing enhanced maneuverability, redundancy, and greater thrust efficiency for larger ships or vessels operating in challenging conditions. The choice between single screw and twin screw configurations depends on vessel size, required power, maneuverability needs, and operational environment.

Overview of Single Screw Arrangement

Single screw arrangements involve one rotating screw that transports material through a barrel, commonly used in extrusion and injection molding processes. This design offers simpler construction, lower cost, and ease of maintenance compared to twin screw systems but may have limitations in mixing efficiency and handling complex materials. Ideal for processing homogeneous materials, single screw extruders provide consistent output and straightforward operation in plastic and food industries.

Overview of Twin Screw Arrangement

Twin screw arrangements involve two intermeshing screws rotating in opposite directions, enhancing material mixing and conveying efficiency compared to single screw systems. This configuration provides superior shear and elongational flow, making it ideal for processing polymers, food products, and chemicals requiring consistent blending and heat transfer. Twin screw designs enable better control over residence time and pressure, reducing the risk of degradation and improving overall product quality.

Comparative Efficiency: Single vs Twin Screw

Twin screw arrangements offer higher mechanical efficiency due to better synchronization and reduced slippage compared to single screw setups. Single screw systems often experience increased friction losses and lower volumetric efficiency, impacting overall performance in material conveyance or extrusion processes. The enhanced intermeshing design of twin screws provides improved mixing, consistent output, and energy savings, making them preferable for applications demanding precision and reliability.

Maneuverability Differences

Twin screw arrangements offer superior maneuverability compared to single screw systems due to independent control of propellers, allowing for precise steering, quicker turning, and effective counter-rotational thrust. Single screw vessels rely on rudder adjustments behind a single propeller, which limits directional control and slows response during low-speed maneuvers. The enhanced handling of twin screws is especially advantageous in confined waterways, docking, and dynamic positioning scenarios.

Installation and Maintenance Considerations

Single screw arrangements typically require simpler installation due to fewer components and reduced alignment challenges, resulting in lower initial setup time. Twin screw configurations demand precise alignment and more complex foundation requirements to ensure proper meshing and bearing support, influencing both installation complexity and cost. Maintenance of single screw systems is generally easier with fewer moving parts, whereas twin screw setups require more frequent inspection and lubrication to manage increased mechanical complexity and prevent premature wear.

Fuel Consumption and Operational Costs

A twin screw arrangement generally offers better fuel efficiency compared to a single screw system due to improved propulsion efficiency and maneuverability, which reduces fuel consumption during operation. Operational costs tend to be higher for twin screw configurations because of increased maintenance requirements and more complex engineering components. However, the fuel savings and enhanced performance can offset these costs, especially in vessels requiring high maneuverability and redundancy.

Applications in Vessel Types

Single screw arrangements are commonly used in smaller vessels such as fishing boats, workboats, and patrol vessels due to their simplicity, cost-effectiveness, and ease of maintenance. Twin screw configurations are preferred in larger ships like ferries, tugs, and naval vessels, offering enhanced maneuverability, higher propulsion efficiency, and improved redundancy. The choice between single and twin screw propulsion directly affects vessel performance in specific maritime applications, including speed requirements and operational environments.

Reliability and Redundancy Aspects

Twin screw arrangements offer enhanced reliability and redundancy compared to single screw systems due to the presence of two intermeshing screws that provide continuous operation even if one screw encounters issues. In single screw configurations, a failure or wear in the screw often leads to complete system downtime, whereas twin screws share the load, reducing wear and risk of catastrophic failure. This redundancy in twin screw designs translates to improved operational stability and less maintenance-related interruptions.

Conclusion: Choosing the Optimal Screw Arrangement

Selecting the optimal screw arrangement depends on application-specific requirements such as torque transmission, load capacity, and space constraints. Single screw systems offer simplicity, lower cost, and ease of maintenance, making them suitable for lighter loads and less demanding environments. Twin screw arrangements provide enhanced torque capacity, improved load distribution, and greater stability, ideal for high-performance applications requiring precision and durability.

Propeller Efficiency

Twin screw arrangements generally offer higher propeller efficiency than single screw setups by reducing hull resistance and improving maneuverability.

Maneuverability

Twin screw arrangements significantly enhance maneuverability by providing independent propeller control, allowing for tighter turns and improved handling compared to single screw systems.

Rudder Effectiveness

Twin screw arrangements significantly enhance rudder effectiveness by generating more balanced and increased water flow across the rudder surfaces compared to single screw setups.

Shaft Alignment

Twin screw arrangements offer superior shaft alignment stability compared to single screw setups, minimizing vibration and wear for enhanced machinery performance.

Stern Tube Bearing

Twin screw arrangements in Stern Tube Bearings provide enhanced alignment and reduced vibration compared to single screw configurations, optimizing durability and operational efficiency in marine propulsion systems.

Cavitation

Twin screw arrangements reduce cavitation risks more effectively than single screw setups by promoting smoother fluid flow and minimizing pressure fluctuations.

Hull Form Resistance

Twin screw arrangements typically reduce hull form resistance by improving wake flow and distributing thrust more evenly compared to single screw configurations, enhancing propulsion efficiency.

Turning Circle Diameter

Twin screw arrangements typically offer a smaller turning circle diameter compared to single screw configurations, enhancing maneuverability.

Thrust Deduction

Twin screw arrangements typically exhibit lower thrust deduction compared to single screw configurations, resulting in improved propulsion efficiency and reduced hull resistance.

Engine Redundancy

Twin screw arrangements enhance engine redundancy by providing each propeller with independent power sources, reducing the risk of total propulsion failure compared to single screw systems.

single screw vs twin screw arrangement Infographic

njnir.com

njnir.com