Air lubrication systems reduce frictional resistance by creating a layer of bubbles between the hull and seawater, enhancing fuel efficiency and lowering emissions. Hull coatings provide a protective barrier that minimizes biofouling, maintaining smooth hull surfaces and preventing drag increase over time. Combining air lubrication with advanced hull coatings can optimize vessel performance by addressing both frictional resistance and surface roughness.

Table of Comparison

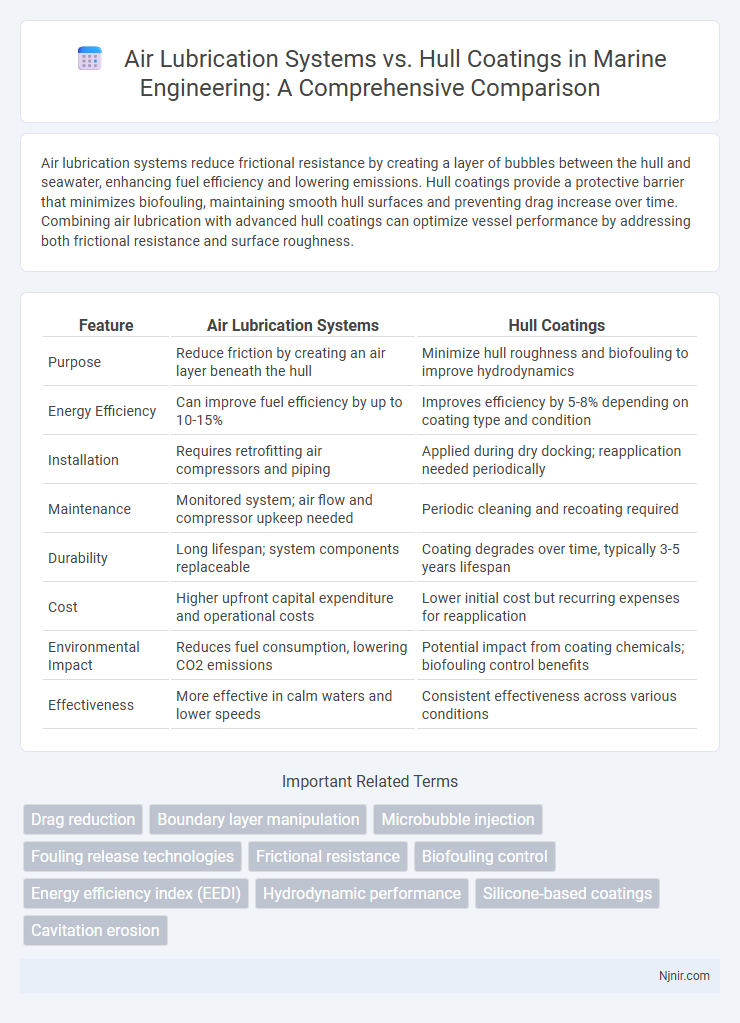

| Feature | Air Lubrication Systems | Hull Coatings |

|---|---|---|

| Purpose | Reduce friction by creating an air layer beneath the hull | Minimize hull roughness and biofouling to improve hydrodynamics |

| Energy Efficiency | Can improve fuel efficiency by up to 10-15% | Improves efficiency by 5-8% depending on coating type and condition |

| Installation | Requires retrofitting air compressors and piping | Applied during dry docking; reapplication needed periodically |

| Maintenance | Monitored system; air flow and compressor upkeep needed | Periodic cleaning and recoating required |

| Durability | Long lifespan; system components replaceable | Coating degrades over time, typically 3-5 years lifespan |

| Cost | Higher upfront capital expenditure and operational costs | Lower initial cost but recurring expenses for reapplication |

| Environmental Impact | Reduces fuel consumption, lowering CO2 emissions | Potential impact from coating chemicals; biofouling control benefits |

| Effectiveness | More effective in calm waters and lower speeds | Consistent effectiveness across various conditions |

Introduction to Air Lubrication Systems and Hull Coatings

Air lubrication systems reduce friction between the ship hull and water by generating a layer of microbubbles that decreases hydrodynamic resistance, enhancing fuel efficiency and reducing greenhouse gas emissions. Hull coatings involve applying specialized materials such as silicone-based or epoxy paints to create a smooth, anti-fouling surface that prevents marine organism attachment and lowers drag. Combining air lubrication systems with advanced hull coatings maximizes vessel performance by optimizing both physical surface conditions and hydrodynamic flow.

Principles and Mechanisms of Air Lubrication

Air lubrication systems reduce frictional resistance by creating a thin layer of air bubbles along the hull surface, which decreases the wetted surface area and hydrodynamic drag. This mechanism contrasts with hull coatings that primarily alter surface roughness and adhesion properties to minimize friction and biofouling. By continuously injecting air under the hull, air lubrication systems generate a low-viscosity air layer that significantly improves energy efficiency and lowers fuel consumption.

Advanced Hull Coating Technologies

Advanced hull coating technologies utilize nanostructured polymers and antifouling biocides to reduce drag and prevent biofouling, enhancing vessel fuel efficiency and durability. These coatings create a smoother surface that minimizes resistance and inhibits marine organism attachment without requiring additional energy input. Compared to air lubrication systems, which rely on air bubbles to reduce friction, advanced coatings offer a passive, low-maintenance solution with long-lasting performance benefits in harsh marine environments.

Comparative Fuel Efficiency and Energy Savings

Air lubrication systems reduce friction by creating a layer of air bubbles along the hull, achieving fuel savings of up to 15% compared to traditional hull coatings, which typically offer fuel efficiency improvements of around 5-10%. These systems are particularly effective for large vessels operating at steady speeds, where energy savings can translate into substantial cost reductions over time. While hull coatings improve smoothness and reduce drag by preventing biofouling, air lubrication provides a more significant reduction in hydrodynamic resistance, resulting in higher overall energy efficiency.

Impact on Vessel Hydrodynamics

Air lubrication systems reduce frictional resistance by introducing a layer of microbubbles along the hull surface, significantly improving vessel hydrodynamics and fuel efficiency. Hull coatings enhance hydrodynamics by minimizing surface roughness and preventing biofouling, thereby reducing drag and maintaining optimal flow conditions. Combining advanced air lubrication technology with specialized antifouling hull coatings maximizes drag reduction and supports sustained vessel performance.

Environmental Benefits and Challenges

Air lubrication systems reduce frictional resistance by creating a layer of air bubbles along the hull, significantly cutting fuel consumption and CO2 emissions, thus enhancing environmental sustainability in maritime transport. Hull coatings, especially those with low-friction or antifouling properties, minimize biofouling and drag, reducing fuel use and preventing the spread of invasive species, although some coatings may contain biocides harmful to marine ecosystems. While air lubrication offers a chemical-free solution with potential for widespread emission reductions, challenges include system maintenance and energy use, whereas hull coatings face regulatory restrictions and effectiveness variability depending on water conditions.

Installation and Maintenance Requirements

Air lubrication systems require complex installation involving the integration of air compressors, piping, and control systems within the vessel's hull, often necessitating dry-docking and skilled technicians. Maintenance demands regular inspection and cleaning of air diffusers and compressors to ensure consistent bubble generation and system efficiency. In contrast, hull coatings are applied during routine dry-docking using specialized paint systems with minimal disruption, offering lower ongoing maintenance primarily focused on periodic inspection and touch-ups to preserve antifouling properties.

Performance in Different Operating Conditions

Air lubrication systems improve vessel performance by reducing frictional resistance through a layer of microbubbles, enhancing fuel efficiency notably at steady cruising speeds and moderate sea states. Hull coatings decrease biofouling and surface roughness, maintaining performance across variable speeds and harsh operating conditions such as heavy marine growth or abrasive environments. Performance of air lubrication is more sensitive to speed and sea conditions, while advanced hull coatings offer consistent resistance reduction across a wider range of operating profiles.

Cost Analysis and Return on Investment

Air lubrication systems require a high initial capital investment, often ranging from $500,000 to $2 million depending on vessel size, but can reduce fuel consumption by up to 10%, leading to significant operational cost savings over time. Hull coatings generally cost between $50,000 and $200,000 per application, with effective lifespan of 3 to 5 years, and provide fuel savings of around 5% by reducing frictional resistance. Evaluating return on investment involves balancing the higher upfront costs and maintenance of air lubrication systems against the lower costs and periodic reapplication of hull coatings, with ROI timelines typically shorter for coatings but potentially greater long-term savings from air lubrication.

Future Trends in Hull Friction Reduction Technologies

Emerging trends in hull friction reduction technologies focus on integrating air lubrication systems with advanced hull coatings to maximize efficiency and fuel savings. Innovative microbubble generation and optimized coating materials are designed to work synergistically, reducing drag and minimizing biofouling under varied sea conditions. The increasing adoption of smart sensors and AI-driven control systems enables real-time monitoring and adjustment, enhancing the performance and sustainability of next-generation maritime vessels.

Drag reduction

Air lubrication systems reduce hull drag by creating a consistent layer of microbubbles that minimize water resistance, outperforming traditional hull coatings which rely primarily on surface smoothness and antifouling properties.

Boundary layer manipulation

Air lubrication systems reduce friction drag by injecting air bubbles under the hull to alter the boundary layer, while hull coatings minimize surface roughness to smooth water flow and control the boundary layer.

Microbubble injection

Microbubble injection in air lubrication systems significantly reduces ship hull friction more effectively than traditional hull coatings by creating a persistent low-resistance layer of air bubbles along the underwater surface.

Fouling release technologies

Air lubrication systems reduce drag by creating a stable bubble layer on the hull, while fouling release hull coatings minimize marine organism adhesion through smooth, low-friction surfaces, both enhancing vessel efficiency by addressing biofouling with complementary technologies.

Frictional resistance

Air lubrication systems reduce frictional resistance by creating a layer of bubbles that minimizes hull-water contact, whereas hull coatings primarily lower friction by altering the hull surface texture to prevent biofouling.

Biofouling control

Air lubrication systems reduce biofouling by minimizing hull-water contact through microbubbles, while hull coatings prevent biofouling by creating a toxic or slick surface that inhibits organism attachment.

Energy efficiency index (EEDI)

Air lubrication systems reduce hull friction by injecting air bubbles, significantly improving the Energy Efficiency Design Index (EEDI) compared to traditional hull coatings that primarily offer passive resistance reduction.

Hydrodynamic performance

Air lubrication systems reduce hull friction by generating a layer of microbubbles, significantly enhancing hydrodynamic performance compared to traditional hull coatings that rely solely on smooth surfaces to minimize drag.

Silicone-based coatings

Silicone-based hull coatings reduce friction by creating a smooth, hydrophobic surface, while air lubrication systems improve vessel efficiency by generating microbubbles to decrease drag beneath the hull.

Cavitation erosion

Air lubrication systems reduce cavitation erosion more effectively than traditional hull coatings by minimizing direct water-hull contact through a persistent air layer that dissipates bubble collapse energy.

Air lubrication systems vs Hull coatings Infographic

njnir.com

njnir.com