A sea chest is an integral marine engineering component that serves as an intake reservoir on a ship's hull, allowing seawater to enter cooling and ballast systems while protecting against debris and marine life. Strainers are installed downstream of the sea chest to filter out smaller particles and contaminants, ensuring the purity of water entering pumps and other critical machinery. Proper maintenance and selection of sea chests and strainers enhance the efficiency and longevity of propulsion and onboard systems by preventing blockages and corrosion.

Table of Comparison

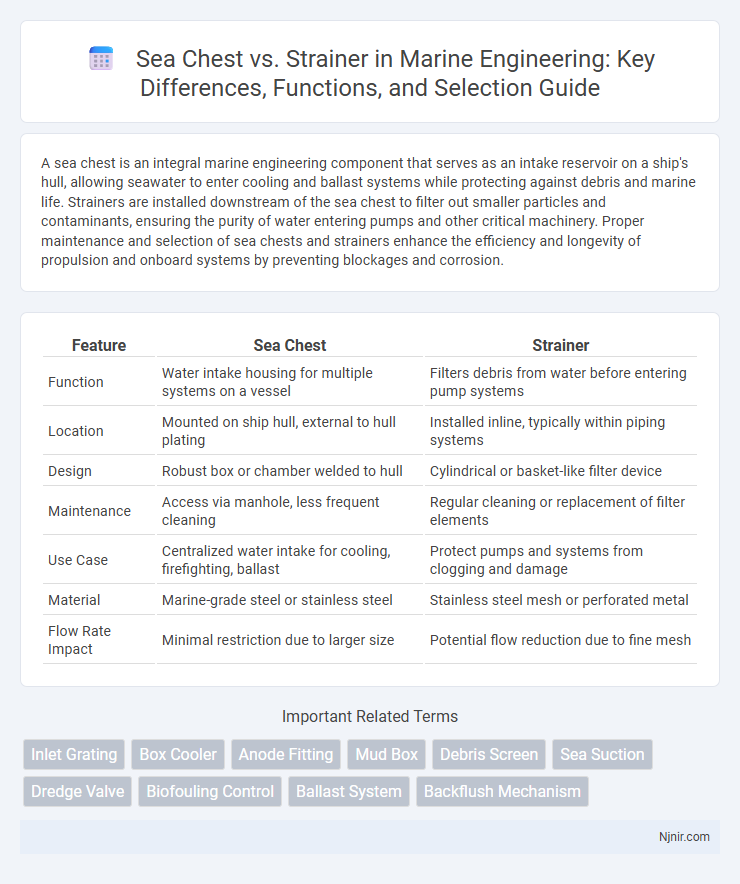

| Feature | Sea Chest | Strainer |

|---|---|---|

| Function | Water intake housing for multiple systems on a vessel | Filters debris from water before entering pump systems |

| Location | Mounted on ship hull, external to hull plating | Installed inline, typically within piping systems |

| Design | Robust box or chamber welded to hull | Cylindrical or basket-like filter device |

| Maintenance | Access via manhole, less frequent cleaning | Regular cleaning or replacement of filter elements |

| Use Case | Centralized water intake for cooling, firefighting, ballast | Protect pumps and systems from clogging and damage |

| Material | Marine-grade steel or stainless steel | Stainless steel mesh or perforated metal |

| Flow Rate Impact | Minimal restriction due to larger size | Potential flow reduction due to fine mesh |

Introduction to Sea Chests and Strainers in Marine Engineering

Sea chests and strainers are essential components in marine engineering, designed to manage seawater intake for ship systems. A sea chest serves as a recessed intake chamber in the ship's hull, providing a protected entry point for cooling water, while strainers are installed inside or near the sea chest to filter out debris and prevent damage to pumps and machinery. Understanding their distinct roles ensures efficient seawater flow management and protection of critical shipboard equipment.

Purpose and Functionality of Sea Chests

Sea chests serve as integral intake points on a ship's hull, designed to house strainers and other filtration devices that protect onboard systems from debris and marine life. Their primary function is to facilitate the controlled intake of seawater for cooling, firefighting, or ballast operations while preventing clogging and damage to critical machinery. Unlike strainers, which are filtration components, sea chests provide the structural enclosure and connection to the vessel's piping system, ensuring efficient and safe water flow.

Purpose and Functionality of Strainers

Strainers serve as essential components in marine systems, designed to filter out debris and prevent clogging within pipelines by trapping particles before they enter pumps or other equipment. Unlike sea chests, which act as intake repositories for seawater, strainers focus primarily on maintaining fluid cleanliness to ensure efficient operation and protect mechanical parts from damage. Their functionality includes removing contaminants from water flow, reducing maintenance needs, and enhancing the longevity of marine propulsion and cooling systems.

Key Design Differences Between Sea Chests and Strainers

Sea chests are large, enclosed compartments built into a vessel's hull to intake seawater for various onboard systems, featuring multiple inlet openings and internal baffles to reduce debris entry and flow turbulence. Strainers are smaller, removable devices installed inline within piping systems to filter out solids using mesh or perforated screens, designed primarily for ease of cleaning and maintenance. The key design difference lies in the sea chest's role as a primary intake structure integrated into the ship's hull, whereas strainers serve as secondary filtration components focused on protecting internal machinery by trapping particles from the incoming water.

Materials Used in Sea Chests and Strainers

Sea chests are commonly constructed from durable materials such as cast steel, cast iron, or bronze to withstand harsh marine environments and corrosion. Strainers, often made from stainless steel or bronze, focus on corrosion resistance and ease of maintenance while ensuring effective filtration of seawater or other fluids. Both components prioritize materials that balance strength, corrosion resistance, and longevity to maintain reliable operation in marine and industrial systems.

Installation and Maintenance Procedures

Sea chests require precise hull integration and watertight sealing to ensure proper water intake and system protection, often involving welding and flange installation. Strainers are installed inline within piping systems, focusing on ease of access for regular cleaning and debris removal to maintain optimal flow. Routine maintenance for sea chests includes inspection for corrosion and fouling, while strainers demand frequent mesh cleaning or replacement to prevent clogging and system strain.

Operational Challenges and Solutions

Sea chests often face operational challenges such as clogging due to marine debris and biofouling, leading to reduced water flow and potential engine cooling issues. Strainers are designed to minimize these problems by filtering out larger particles before water enters the system, but they require regular maintenance to prevent clogging that can impede performance. Implementing routine inspection protocols and using advanced anti-fouling coatings on sea chests and strainers enhances operational reliability and reduces downtime in marine vessels.

Impact on Vessel Performance and Safety

A sea chest serves as the intake structure on a vessel, housing strainers that filter out debris to protect the cooling and ballast systems, directly impacting engine efficiency and operational safety. Properly maintained strainers prevent clogging and ensure continuous seawater flow, thereby avoiding engine overheating and potential mechanical failures. The combined functionality of sea chests and strainers is critical for maintaining optimal vessel performance and minimizing the risk of safety incidents during navigation.

Regulatory Standards and Compliance

Sea chests and strainers must comply with regulatory standards such as those set by the International Maritime Organization (IMO) and classification societies like ABS and Lloyd's Register to ensure vessel safety and environmental protection. Sea chests require adherence to SOLAS (Safety of Life at Sea) regulations for structural integrity and corrosion resistance, while strainers must meet specific flow rate and filtration standards to prevent marine organism ingress and protect engine cooling systems. Both components undergo rigorous testing and certification to maintain compliance with maritime operational guidelines and pollution prevention mandates.

Choosing Between Sea Chest and Strainer: Factors to Consider

Choosing between a sea chest and a strainer hinges on factors such as vessel size, flow rate requirements, and maintenance accessibility. Sea chests offer greater capacity and protection for intake systems on larger ships, while strainers are compact and ideal for smaller vessels with lower water volumes. Evaluating environmental conditions, fouling potential, and ease of cleaning ensures optimal selection for marine water intake systems.

Inlet Grating

Inlet gratings on sea chests prevent large debris from entering the cooling system, whereas strainers further filter smaller particles to protect marine engine components.

Box Cooler

The box cooler's sea chest efficiently houses strainers to filter incoming seawater, preventing debris from entering the cooling system and ensuring optimal engine performance.

Anode Fitting

Sea chest anode fittings provide superior corrosion protection compared to strainer anode fittings by offering larger surface area coverage and enhanced seawater flow circulation.

Mud Box

A sea chest houses the mud box, a critical component that collects debris and sediment before water passes through the strainer, ensuring efficient filtration and protecting the vessel's cooling system.

Debris Screen

A Sea Chest typically houses a Debris Screen designed to prevent large particles from entering the vessel's seawater intake system, whereas a Strainer specifically filters smaller debris to protect pumps and equipment downstream.

Sea Suction

Sea suctions equipped with sea chests provide superior flow stability and debris protection compared to strainers, enhancing marine engine cooling efficiency.

Dredge Valve

The dredge valve in sea chests provides robust protection against debris and sediment compared to strainers, ensuring efficient water intake for marine and dredging operations.

Biofouling Control

Sea chests with removable strainers provide enhanced biofouling control by allowing easier cleaning and inspection compared to fixed strainers.

Ballast System

A sea chest in a ballast system acts as the seawater intake housing, while strainers protect pumps by filtering debris before water enters the ballast tanks.

Backflush Mechanism

The Sea Chest utilizes a backflush mechanism by reversing water flow to clear debris, whereas the Strainer relies mainly on manual cleaning without an integrated backflush system.

Sea Chest vs Strainer Infographic

njnir.com

njnir.com