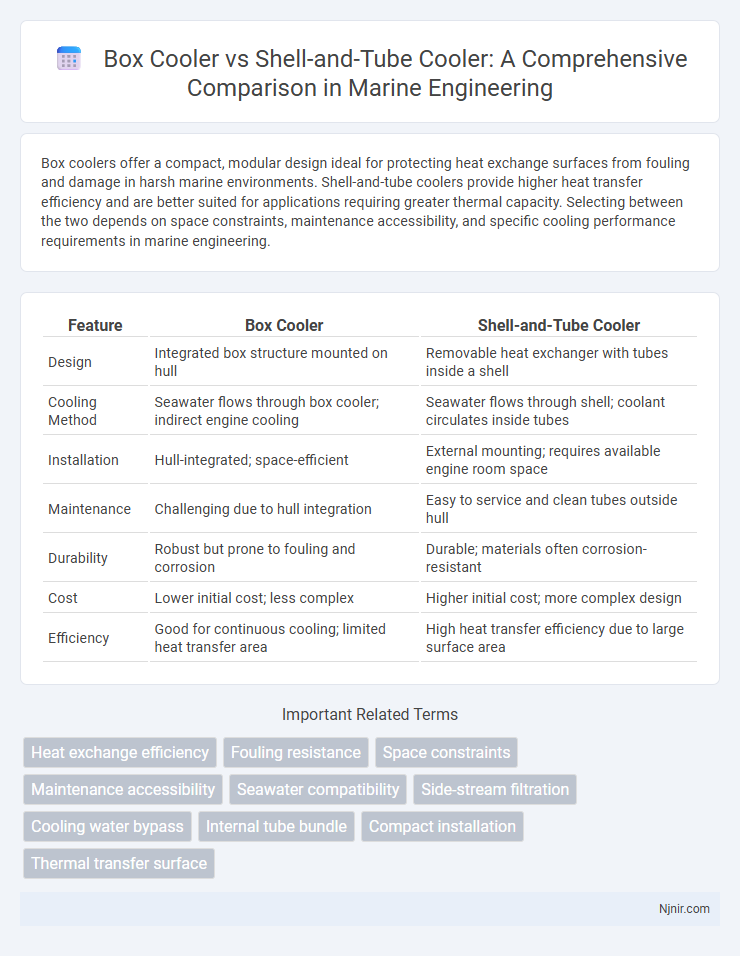

Box coolers offer a compact, modular design ideal for protecting heat exchange surfaces from fouling and damage in harsh marine environments. Shell-and-tube coolers provide higher heat transfer efficiency and are better suited for applications requiring greater thermal capacity. Selecting between the two depends on space constraints, maintenance accessibility, and specific cooling performance requirements in marine engineering.

Table of Comparison

| Feature | Box Cooler | Shell-and-Tube Cooler |

|---|---|---|

| Design | Integrated box structure mounted on hull | Removable heat exchanger with tubes inside a shell |

| Cooling Method | Seawater flows through box cooler; indirect engine cooling | Seawater flows through shell; coolant circulates inside tubes |

| Installation | Hull-integrated; space-efficient | External mounting; requires available engine room space |

| Maintenance | Challenging due to hull integration | Easy to service and clean tubes outside hull |

| Durability | Robust but prone to fouling and corrosion | Durable; materials often corrosion-resistant |

| Cost | Lower initial cost; less complex | Higher initial cost; more complex design |

| Efficiency | Good for continuous cooling; limited heat transfer area | High heat transfer efficiency due to large surface area |

Introduction to Marine Cooling Systems

Marine cooling systems are essential for maintaining optimal engine temperatures to prevent overheating and ensure efficient operation. Box coolers utilize seawater flowing through a box-shaped shell to cool the engine coolant indirectly, offering compact design and corrosion resistance. Shell-and-tube coolers feature a bundle of tubes within a cylindrical shell, providing higher heat transfer efficiency and easier maintenance, making them suitable for larger vessels with demanding cooling requirements.

Box Cooler: Design and Functionality

Box coolers feature a compact design with integrated water channels that maximize heat exchange efficiency by allowing seawater to flow directly through the box structure, effectively cooling fluids in marine engines and machinery. Their modular construction facilitates easy installation and maintenance, reducing downtime in maritime applications. Unlike shell-and-tube coolers, box coolers use the surrounding seawater as a heat sink without requiring additional piping, making them highly efficient for engine cooling in ship systems.

Shell-and-Tube Cooler: Design and Operation

Shell-and-tube coolers consist of a series of tubes enclosed within a cylindrical shell, where heat exchange occurs between fluids flowing inside the tubes and the fluid in the shell. This design allows efficient thermal transfer with high durability, making them ideal for high-pressure and high-temperature applications. Their operation is characterized by adjustable flow rates, ease of maintenance, and suitability for various industrial processes requiring robust and effective cooling solutions.

Efficiency Comparison in Marine Environments

Box coolers offer higher efficiency in marine environments due to their direct seawater cooling design, minimizing heat transfer resistance and allowing rapid temperature dissipation. Shell-and-tube coolers rely on a complex arrangement of tubes, which can lead to fouling and reduced thermal conductivity, lowering overall efficiency in saltwater applications. Marine vessels benefit from box coolers' compact structure and ease of maintenance, contributing to sustained thermal performance and fuel economy.

Installation and Space Requirements

Box coolers feature a compact design that simplifies installation in tight engine compartments, often mounting directly onto the engine block to save space. Shell-and-tube coolers require more room due to their larger size and need for separate mounting, making them less suitable for confined spaces. The simpler, integrated installation of box coolers reduces labor time and minimizes additional support structures compared to the more complex setup of shell-and-tube coolers.

Maintenance and Durability Considerations

Box coolers offer simpler maintenance due to accessible heat exchange surfaces and fewer complex components, reducing downtime and repair costs. Shell-and-tube coolers, while more durable under high-pressure and high-temperature conditions, require regular inspection to prevent tube corrosion and fouling, increasing maintenance complexity. Material selection and operational environment significantly impact the longevity and upkeep requirements of both cooler types.

Performance in Fouling and Corrosive Conditions

Box coolers exhibit superior resistance to fouling and corrosion compared to shell-and-tube coolers due to their simpler design and self-cleaning water flow patterns, minimizing buildup and enhancing heat transfer efficiency. Shell-and-tube coolers, while effective in controlled environments, often suffer from clogging and corrosion in harsh or contaminated waters, leading to increased maintenance and reduced thermal performance. The choice between the two hinges on operating conditions; box coolers are preferred in seawater or fouling-prone environments, whereas shell-and-tube units perform better with treated or clean fluids.

Energy Consumption and Cost Analysis

Box coolers offer lower energy consumption due to their compact design and efficient heat transfer surface, often reducing pumping power requirements compared to shell-and-tube coolers. Shell-and-tube coolers typically incur higher operational costs because of increased water usage and maintenance complexity, which affect overall lifecycle expenses. Cost analysis reveals that while box coolers have higher initial installation costs, their energy savings and reduced maintenance often lead to lower total cost of ownership in industrial cooling applications.

Suitability for Vessel Types and Applications

Box coolers are ideal for ships with limited hull space, such as small to medium-sized vessels, because they can be integrated directly into the hull, offering efficient heat exchange without requiring external piping. Shell-and-tube coolers suit larger vessels and offshore platforms where high cooling capacity and ease of maintenance are critical, as their modular design accommodates higher pressure and temperature ranges. Both coolers serve distinct marine applications, with box coolers preferred for compact installations and shell-and-tube coolers favored for heavy-duty, high-performance cooling needs.

Future Trends in Marine Cooling Technology

Future trends in marine cooling technology emphasize enhanced efficiency and durability in box cooler and shell-and-tube cooler designs, leveraging advanced materials and coatings to resist corrosion and biofouling. Integration of smart sensors and IoT-enabled monitoring systems is driving predictive maintenance and real-time performance optimization in both cooler types. Innovations in compact, energy-efficient heat exchangers support greener operations and comply with evolving maritime environmental regulations.

Heat exchange efficiency

Box coolers offer higher heat exchange efficiency in compact spaces due to direct water cooling, while shell-and-tube coolers provide superior performance for larger heat loads through extensive surface area and fluid flow optimization.

Fouling resistance

Box coolers exhibit superior fouling resistance compared to shell-and-tube coolers due to their larger flow passages and streamlined design that reduce sediment buildup and enhance maintenance access.

Space constraints

Box coolers offer a compact design ideal for tight space constraints, whereas shell-and-tube coolers require more installation space due to their larger and more complex structure.

Maintenance accessibility

Box coolers offer easier maintenance accessibility due to their compact, modular design allowing straightforward cleaning and repairs, whereas shell-and-tube coolers often require extensive disassembly and specialized tools for maintenance.

Seawater compatibility

Shell-and-tube coolers offer superior seawater compatibility due to their robust corrosion-resistant materials and ability to handle high salinity and biofouling compared to box coolers.

Side-stream filtration

Side-stream filtration in box coolers offers easier maintenance and improved contaminant removal compared to the more complex and less accessible filtration setup in shell-and-tube coolers.

Cooling water bypass

Box coolers provide efficient cooling water bypass by utilizing internal channels for direct water flow, while shell-and-tube coolers rely on external bypass valves to regulate cooling water circulation.

Internal tube bundle

Box coolers feature a compact internal tube bundle designed for efficient heat transfer and easy maintenance, whereas shell-and-tube coolers have a larger, more complex internal tube bundle optimized for higher thermal capacity and pressure tolerance.

Compact installation

Box coolers offer a more compact installation footprint compared to shell-and-tube coolers, making them ideal for space-constrained environments.

Thermal transfer surface

Box coolers provide a compact thermal transfer surface ideal for seawater cooling, while shell-and-tube coolers offer a larger, customizable surface area for more efficient heat exchange in high-demand industrial applications.

box cooler vs shell-and-tube cooler Infographic

njnir.com

njnir.com